Problems

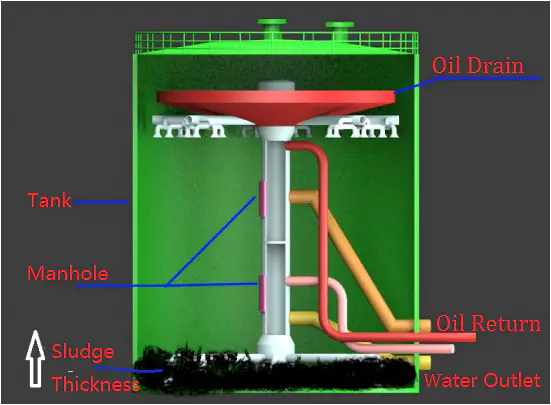

① The polymer injected during the drilling process will be withdrawn from the well with the gel as the well is mined. When these gels and polymers are put into the reverse phase demulsifier, they are precipitated from the sewage and settled to the bottom of the settling tank. However, these things do not settle in liquid form, but adhere to sewage oil and sediment, and settle in a solid state in a tank. The discharge is extremely difficult, and the production has to be stopped every year to clean up, which is very expensive.

② The inner wall of the oil pipeline is gradually corroded to form rust during long-term transportation, and the rust will also settle at the bottom of the tank with the transportation of crude oil.

③ Crude oil contains a large amount of organic matter, and various bacteria are hidden in the sludge environment.

④ After the sediment has accumulated to a certain height, it may flow into the filtration system with the sedimentation water, which will greatly damage the water quality of the system, and may also form a vicious circle, affecting the normal use and function of other equipment.

Solutions

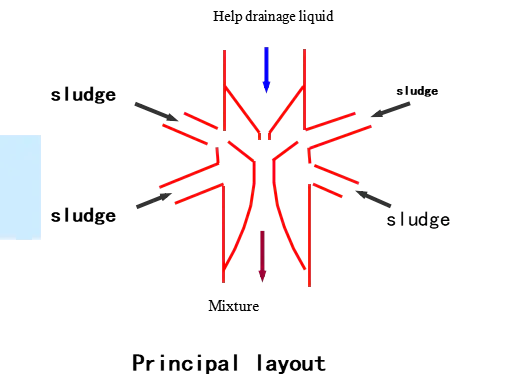

① Principal

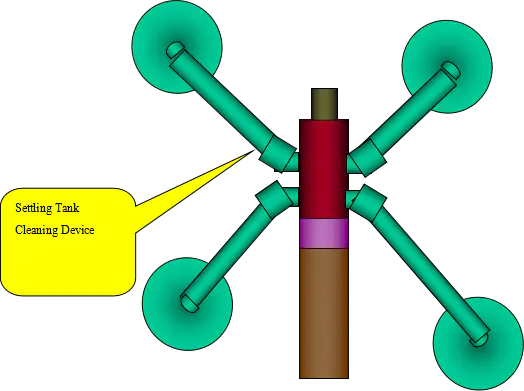

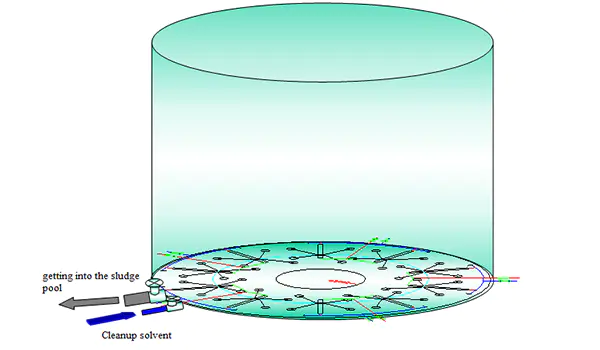

The high-pressure mud discharging technology is to form a large number of suction cup spaces in the bottom of the tank through the layout of the pipeline, and the liquid is moved to form a vacuum at the suction cup position, thereby discharging the sludge from the tank body.

② On-site Operation

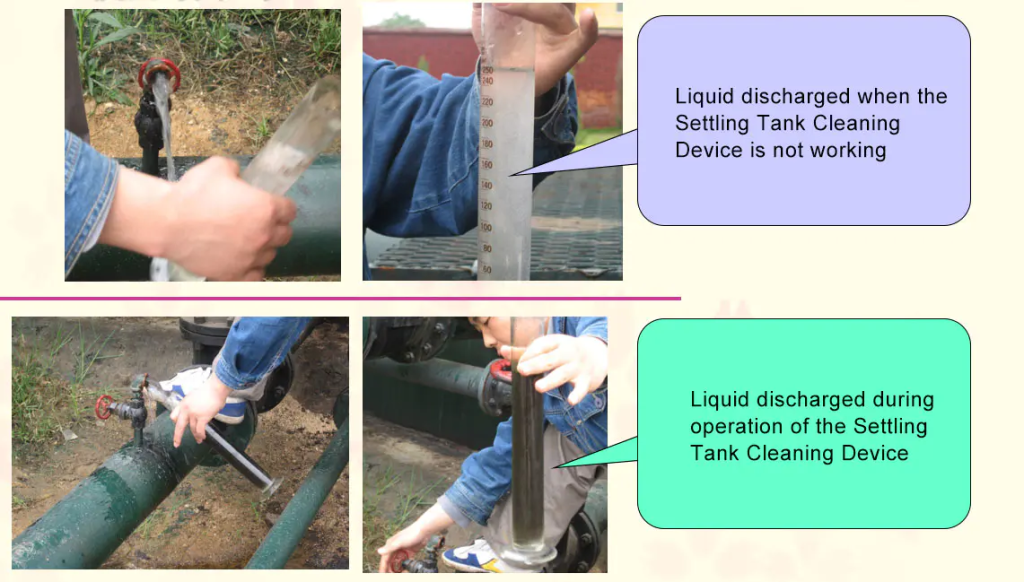

By using the Settling Tank Cleaning Device, the discharge liquid has significant changes.

Features

① Reduce the frequency of manual tank cleaning to one time per 3 years, saving the cost of manual tank cleaning;

② Reducing the working load of the filter tank and saving the filter material cost;

③ Reduce the frequency of filter washing and clearing, and save water resources;

④ Improve the quality of sewage treatment and reduce pollution to reservoirs;

⑤ Solved the problem of pollution of the environment caused by high oily sludge piled up in the past during manual tank cleaning, which reduced the labor load of the workers, reduced the production time, reduced the operating load of the filtering equipment, and prolonged the service life of the equipment.