Problems

In the past, a cementing truck must be equipped at the well site to complete the pressure test.

- 1/2 discharge pipe 28 meters high pipe string + control head + cable to quickly complete the pressure test;

- The well site has no power;

- Rapid injection of methanol or ethylene glycol must occur when ice is blocked

How to deal with it?

Technical Difficulties:

- The flow rate of the pressure test pump should meet the requirements(the customer requires the pressure test to be completed within 15 minutes)

- The size and weight should not be too large.

- The upper part of the nozzle is connected to the control head with a cable and a sealed flow tube. How is the air in the tubing string discharged?

- There is no water source on the website, and the equipment must have a water storage tank.

Design ideas:

- Use an air-driven hydraulic piston pump.

- Diesel air compressor as the power source (no use electricity)

- Pressure test and unblocking, multi-function

- Dimension and weight are suitable for website requirements (separate, armored + modular)

- Remote automatic control, on-site test pressure map

Technical solutions:

The large flow automatic mobile pressure testing equipment is produced to meet the needs of field testing of various good control equipment in the oil field.

Features

① Using water as the pressure test medium, it can pressurize the hydraulic test from 5MPa-105MPa.

② The max. flow rate is 240L/min, which greatly shortens the test pressure time. It can test pressure on various Christmas trees, blowout preventers, anti-nozzle, various manifolds, downhole tools, and other good control equipment.

③ The whole test process is automatically controlled remotely by the laptop. All test settings can be operated in the automatic console. (If necessary, each valve can also be manually controlled separately) to realize the whole process of pressure tests without the need for people on site. When the system pressure is greater than 5Mpa, the sound and light alarm system starts to work, prompting the site personnel to stay away from the high-pressure area, making the field operation safer.

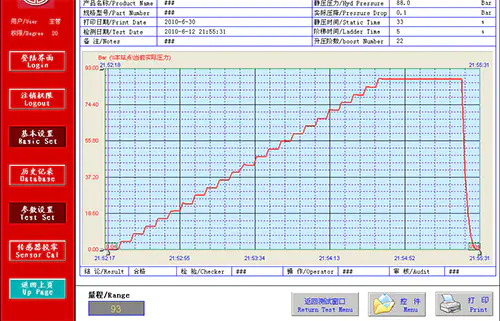

④ The computer automatically generates pressure and time curves, displays them in real-time, and stores various data, and can print out Chinese and English test reports at any time.

⑤ Double pressure relief device – computer automatic pressure relief and manual pressure relief, more safe and reliable; in the event of electrical failure, the system automatically relieves pressure; electric and manual presetting pressure test upper limit, no overpressure, high pressure boosting speed can be controlled.

Performance Data:

- Test medium: clear water

- Air-driven piston pump model: G100+GX60

- Pressure ratio: 1:113

- Max flow: 24L/min

- Max flow of pneumatic diaphragm pump: 878L/min

- Working pressure: 300-1050 bar

- Test workpiece: 1 station output

- Air supply: pressure 8 bar

- Flow rate: 3000 LN/min

- High-pressure water pressure test bench (MHU105KB/WILDEN-T)

- Drive air inlet (PL): Rc1/2″

- Drive air inlet (PL): Rc1/2″

- High-pressure outlet (PA): G1/2 Female

- Water filling outlet (PB): Rc1.5-2″

- High-pressure relief port (PC): G1/2 Female

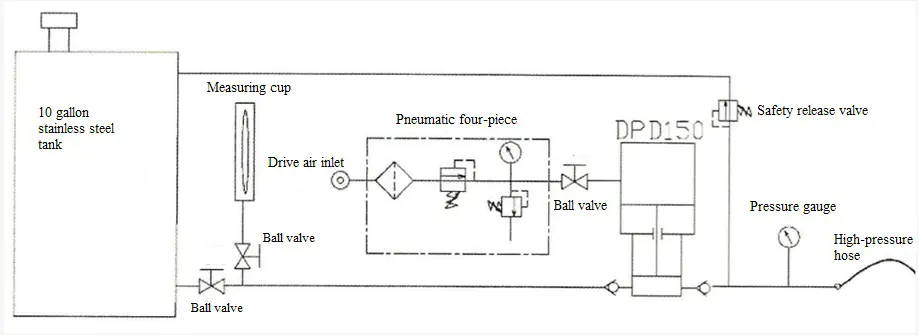

System Schematic Diagram

Major Equipment Configuration

Test Report

Wireless (wired) remote control and alarm system

A wireless transmitting antenna and an alarm are installed on the top of the trailer. The wireless remote control system can be operated remotely within 50 meters. At the same time, the wired control is also installed in the trailer, and can be enabled at any time.

Chemical Injection System

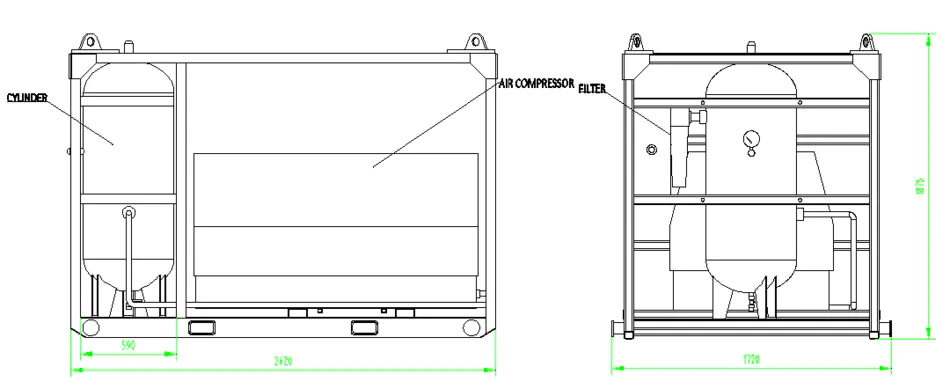

General layout drawing

The system is used for injecting methanol or ethylene glycol into the fluid upstream of the nozzle pipe to prevent the formation fluid from freezing due to the pressure drop, which is one of the most effective means for plugging the wellhead.

The system uses a high-pressure pump that is originally imported from MAXIMATONR Germany. The internal structure of the pump is made of special materials and is suitable for chemical reagents.

- Model: GSF-150

- Max output pressure: 20000 PSI

- Max flow: 100L/H

All equipment and accessories are mounted on the trailer

Reference Size:

- Air compressor unit: 1700mm (L) ×1500mm (W) ×1450 mm (H)

- Weight: 1400kg

- Pressure test unit: 1300mm (L) ×1200mm (W) ×1200 mm (H)

- Weight: 500kg ( no water is added)

(Slightly different internal structure and size according to different configurations)