Automatic Dosing System: How It Can Boost Efficiency?

In modern industrial production, whether for water treatment, chemicals, food processing, or the pharmaceutical industry, precise dosing of chemicals is a major concern in ensuring product quality and process stability.

Manual dosing, which is the traditional practice, has some disadvantages, including enormous operating errors, chemical waste, high labor cost, and unstable reactions.

Accordingly, more companies are adopting automatic dosing system that contain smart control to achieve enhanced precision, safety, and efficiency.

Part 1. What is an Advanced Dosing System?

Advanced dosing system is a blend and automatic chemical dispenser device that achieves precise and real-time chemical dosing through synchronized operation of sensors, controllers, and high-precision metering pumps.

The hardware is made up mainly of the following components:

- Chemical Tank: Stores the chemicals to be dosed.

- Dosing Pump: Controls the flow rate of chemicals and dosing volume.

- Sensors: Monitor in real-time the concentration of chemicals, flow rate, or pH value.

- Controller/PLC: Automatically calculates dosing parameters and accordingly adjusts them.

- Piping and Safety Valve System: Ensures safety and stability during dosing.

With these components working in cooperation, the system can adjust the dosing rate automatically according to process requirements and achieve unattended and precise chemical dosing regulation.

Part 2. Working Principle of an Automatic Chemical Dosing System

The basic working principle of an automatic chemical dosing system is closed-loop control.

Here, sensors are constantly monitoring significant process parameters such as water quality, chemical concentration, or pH level. These real-time readings are then sent to the controller, which cross-completes these real-time readings with the set target value. In the event of a deviation, the controller directly varies the dosing pump speed, stroke length, or duty cycle to precisely control the chemical feed rate to provide optimum process balance.

This dynamic feedback system ensures accuracy of dosing, minimizes chemical waste to practically zero, and maintains system stability even at changing process conditions.

In more sophisticated setups, the system can include IoT-based remote monitoring and data logging. The real-time operating status, dosing trend, and performance reports can be accessed on mobile phones or computers, enabling predictive maintenance, historical trend analysis, and completely digitalized chemical management.

Part 3. Key Features of Advanced Dosing Systems

Smart dosing systems are designed to deliver precise, safe, and efficient chemical dosing through smart automation and rugged engineering. The systems offer real-time monitoring, adaptive control, and high chemical compatibility in meeting the stringent requirements of modern industrial processes. The following are the key features that make them vital in most applications:

High Precision and Consistency

By the use of sensor feedback and self-tuning adjustment schemes, advanced dosing systems can achieve dosing accuracy of ±1%, which provides constant and consistent chemical concentration at any given time. It minimizes over-dosing and under-dosing risks, ensures constant product quality and optimum process performance irrespective of varying operating conditions.

Automation and Intelligence

Through PLC or IoT-control-based dosing units, it is entirely possible to do away with manual intervention. They continuously monitor data and real-time information and automatically make adjustments to the dosing ratio in accordance with changes in the process parameters such as flow rate or chemical concentration.

Trends in the consumption of chemicals can even be predicted using smart algorithms, thus optimizing dosing schedules and reducing manual intervention to near zero.

Safety and Reliability

Advanced dosing systems are built with multiple layers of protection, including leak detection, dry-run protection, pressure relief valves, and alarm systems. These provide safety for people and equipment while traceability of chemicals and compliance with regulations is ensured. Upon detection of abnormal operation, the system automatically shuts down or alarms operators, minimizing potential hazards.

Energy Efficiency and Cost Savings

With optimized motor control, flow paths, and regimes, the system is energy-efficient in use with continuous dosing accuracy. Reduced wear and tear, longer component life, and fewer servicing periods represent significant long-term cost savings for industrial use.

Tough Chemical Compatibility

With a wide range of materials available for use and corrosion-resistant parts, the system supports a large number of chemicals such as acids, alkalis, oxidizers, coagulants, and disinfectants. With its high degree of flexibility, the system is suited to numerous industries such as water treatment, chemical processing, food production, and pharmaceuticals.

Part 4. Wide Range of Industrial Applications

Sophisticated automatic dosing equipment has evolved into a critical element of modern industrial processes, offering precise chemical control in numerous types of industries. Their ability to offer consistent quality, enhance safety, and reduce operating costs makes them extremely beneficial in large-volume and specialty markets too.

Municipal and Industrial Water Treatment

These systems are used in water treatment plants for precise dosing of coagulants, disinfectants, and pH control chemical agents. Automatically responding to real-time water quality data to regulate chemical feed rates, they help keep water parameters stable, improve filtration efficiency, and offer safe, compliant water output.

Automation also helps prevent wastage of chemicals and minimizes manual intervention in what might otherwise be hazardous situations.

Chemical and Pharmaceutical Industries

In chemical processing and pharmaceutical manufacturing, dosing equipment plays a critical role in controlling reaction rates, pH control, and dispensing catalysts, solvents, or neutralizers with very high accuracy. Accurate dosing avoids the consumption of excessive quantities of costly and hazardous reagents, maintains product quality, and optimizes yield. Integration into PLC or SCADA systems facilitates total process traceability and GMP and ISO compliance.

Food and Beverage Processing

In the food and beverage industry, advanced dosing systems are applied for disinfectant injection, mixing of additives, flavoring, and dosing of nutrients. Their food-grade materials and sanitary design enable them to satisfy sanitation standards. Automated chemical dosing also ensures consistent taste and product quality and reducing human error as well as contamination risks.

Agriculture and Greenhouse Irrigation

In modern farming, dosing systems are used for computerized mixing and dispensing of fertilizers, pest control chemicals, and nutrient solutions. By incorporating sensors with software controls, the system adjusts the proportion of chemicals as per soil condition or plant growth stages. This ensures optimum utilization of nutrients, reduces wastage of resources, and ensures sustainable, precision agriculture.

Electronics and Electroplating Industry

Stabilization of chemical concentration in etching baths or tanks is critical in the situation of reproducible product performance in electroplating and electronics manufacturing processes. Chemicals are re-made-up correctly with automatic dosing systems continuously monitoring solution parameters, offering high-quality coatings, reducing defects, and improving process reproducibility.

In all of these industries, Automatic Chemical Dispensing Systems improve production efficiency, promote safety, conservation of the environment, and sustainable operation, allowing companies to achieve more intelligent and more responsible industrial control.

Part 5. Key Benefits of Using High-Tech Dosing Systems

With a sophisticated dosing system, the benefits of automatic dosing systems go beyond simple automation, they offer precision, productivity, and safety at every stage of chemical handling. Such systems are becoming increasingly a driving force for industrial digitalization and environmentally friendly production.

Enhanced Accuracy

Advanced dosing systems ensure chemicals are accurately dosed when and where necessary, according to real-time process feedback. Demand-based, accurate dosing minimizes chemical waste and maintains stable concentration levels, which improves process stability and product quality. This high accuracy also enables regulatory compliance and reduces environmental discharge.

Lower Labor Costs

Once configured, the system can operate automatically 24 hours a day with minimal human supervision. Automated dosing eliminates the need for manual measurement, adjustment, and monitoring, freeing up operators to focus on higher-value tasks. Over time, this significantly reduces labor intensity and long-term staffing expenses.

Improved Safety

By automation of chemical delivery and monitoring, the system minimizes direct human contact with possibly hazardous chemicals. Overpressure protection, leak detection, and remote operation are other benefits that further reduce exposure risks to chemicals or accidents during work, which makes the working place more secure for employees.

Enhanced Efficiency in Production

Automated dose systems ensure continuous and stable operation through constant chemical levels during the process. Changes are avoided, which can result in equipment shutdown or quality issues, thereby improving production efficiency and throughput as a whole. Integration with PLC or IoT also makes predictive maintenance possible, reducing unplanned downtime.

Lowered Maintenance Expenses

Being modular in design, advanced dosing systems facilitate quick inspection, replacement, and upgrading of components without disrupting the overall setup. High-quality and hard-wearing materials and smart design minimize wear and tear, extending service life and minimizing repair requirements, ultimately lowering maintenance costs.

With these all-encompassing advantages, high-tech dosing systems are rapidly becoming a vital part of industrial automation and eco-manufacturing, boosting business towards enhanced productivity, operation safety, and environmental sustainability.

Part 6. Wingoil Automatic Dosing Package: The Ideal Solution for Modular Automatic Chemical Dosing

When it comes to the field of automatic chemical dosing systems, the Wingoil Automatic Dosing Package is a high-end smart module for dosing designed and manufactured internally by the company. Featuring robust integration and stability, it has won universal acknowledgement and favorability from domestic and international customers.

This system is typically applied in a wide range of industries including natural gas, petrochemicals and oil, chemical processing, food, textiles, semiconductors, environmental protection, and water supply. It provides secure, efficient, and precise chemical dosing solutions to demanding processes.

Product Overview

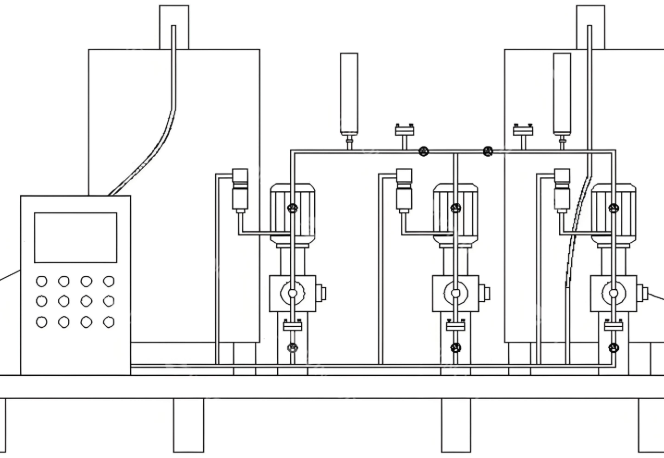

The Automatic Dosing Package by Wingoil is dedicated to high-accuracy metering pumps and features a modular structure consisting of: solution tanks, agitators, level sensors, safety valves, check valves, pressure gauges, pulsation dampeners, filters and piping systems, automatic monitoring and control units, electrical control modules, and a common base platform.

All the elements are attached to one platform according to the process order to form an “armored combination unit” which is simple to install and maintain.

Technical Specifications

| Parameter | Description |

| Recommended Media | Ammonia solution, corrosion inhibitors, sulfuric acid, hydrochloric acid, calcium hydroxide, sodium carbonate, polyacrylamide, phosphates, etc. |

| Max. Pressure | 3000 bar / 0–300 MPa |

| Max. Flow Rate | 0–50 L/min |

In case proper model supply cannot be made or there are special working conditions, Wingoil can deliver custom-made solutions to meet special requirements of diverse industrial uses.

Product Benefits

- Modular Construction: Quick installation and compact footprint.

- High Strength & Anti-Corrosion: Stable and secure operation.

- Accurate Control: Adjustable pressure level and flow rate.

- Automated Operation: Real-time monitoring and alarm functions.

- Tight Quality Control: Ensures stable and reliable equipment operation.

The Wingoil Automatic Dosing Package provides a highly effective solution for the needs of multiple chemical dosing processes and can function as a central unit in assembling smart chemical dosing systems.

Final Thoughts

Advanced dosing systems for chemical dispensing on autopilot are driving the chemical, water treatment, and allied sectors to even more automation and safety. In the future, such systems will be extensively integrated with intelligent sensors, analytics, and cloud-based control, providing businesses with more accurate, cleaner, and highly efficient production options.

If you require a professional supplier of automatic dosing systems or peristaltic dosing pumps, Wingoil is always ready to provide professional technical support and customized services to meet your needs.