Basics about gas-liquid booster pump: The principle, characteristics, and advantages

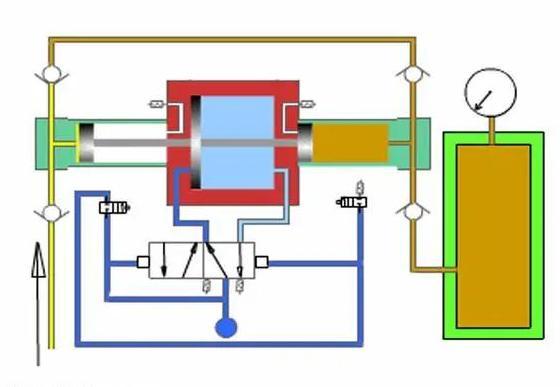

The gas-liquid booster pump is an air-powered pump. The hydraulic oil is continually output at a fixed pressure ratio and utilized to drive the hydraulic actuator to work based on the area difference concept. The automatic gas-liquid pump operates. What are the benefits of a gas-liquid booster pump and how is it used? I’ll walk you through it.

Principle of gas-liquid booster pump

The gas-liquid booster pump serves as a standard liquid delivery pump at the beginning of the connecting process. Currently, the output liquid flow is substantial and the circulation speed is rapid. The resistance that the piston must overcome grows stronger and stronger as the output pressure gradually rises, while the pump’s circulation speed slows down.

The pump will shut off automatically when the reaction force of the output pressure and the pneumatic driving force are equal. The pump is not using any energy at this time because it is in a state of sustaining pressure.

Due to the pump’s low friction resistance, it will automatically start to adjust the pressure when the output pressure decreases or the air supply pressure rises as a result of a leak or another factor. This ensures the output pressure’s dependability.

Characteristics of gas-liquid booster pump

1. High output pressure, which can reach 400MPa for huge output pressure.

2. It has numerous applications. Hydraulic oil, water, and the majority of chemically corrosive liquids (where suitable corrosion-resistant materials are sealed) can all be used as the working medium. It has a long service life, high dependability, and requires no maintenance.

3. It is simple to modify. Steplessly alters the input air pressure within the pump’s operating range by adjusting the pressure regulating valve, and you may do the same for the output hydraulic pressure.

4. Automatic pressure maintenance: Regardless of what causes the pressure in the circuit to drop, the pump will automatically turn on to make up for the leaking pressure and maintain the circuit pressure.

5. Safe operation, gas driven, no arc and spark, can be used in dangerous places.

Advantages of gas-liquid booster pump

1. The pump automatically shuts off upon reaching the desired pressure level, reducing noise, energy use, and environmental impact.

2. The working medium’s temperature does not increase.

3. It does not require a power source and can be used in situations where there is no power source or explosion protection.

4. Compact size, portability, flexible design, with a built-in oil tank or a remote oil source, and less installation area required

5. The output pressure may exceed several hundred MPa.

6. The pressure has no effect, is safer, and does not harm the machinery or its components.

7. The pneumatic drive does not require an additional online lubrication system, which reduces operating costs and prevents oil mist pollution of the environment and human health.

8. Maintenance is easy to do. Threaded connections are used on the pump body. Every worn component is a standard component, making installation and disassembly simple. The reversing valve is mounted externally, making it simple to maintain and replace and giving it a longer lifespan.

9. The pump is unaffected by frequent starting and stopping.

10. The seal leakage overflow hole is set aside to safeguard the pump body and quickly identify any problems with the pump.

11. By modifying the input air pressure, the output liquid pressure can be changed within the pump’s operating pressure range.

12. It can be tailored to the needs of the customer, ranging from straightforward manual operation to totally automatic management.

13. The pressurizing medium is diverse, and water, oil, coolant, lubricating oil, and corrosive fluid can be used.

Gas-liquid booster pump vs ordinary hydraulic station

The gas-liquid booster pump is what kind of machinery? The gas-liquid booster pump is a type of pump product that uses compressed air as the source of power and, using the area difference principle continually produces hydraulic oil in accordance with a predetermined pressurization ratio in order to operate a hydraulic actuator. What distinguishes it from regular hydraulic stations?

1. It saves energy since it can maintain pressure for an extended period of time without using extra energy.

2. Because there is no oil temperature rise, it is appropriate for use in hot, humid environments without ventilation.

3. Gas-liquid – Multi-season Ventanpak in a stuffy, unventilated area.

4. It is adaptable in terms of configuration and modest in size. It can be mounted on the machine tool or come with its own oil tank. To conserve production space, it makes advantage of the machine bed’s space.

5. There is no environmental pollution.

Furthermore, there is no issue with the booster cylinder’s stroke limiting oil flow, as there is with the gas-liquid booster pump, which can automatically and continuously deliver oil.