Dissolvable Frac Plug Experimental Test: Performance Validation Under Harsh Conditions

In modern multi-stage fracturing operations for oil and gas wells, dissolvable frac plugs have become the preferred choice in many downhole tool solutions due to their ability to eliminate milling operations, reduce operation time, and lower overall risk.

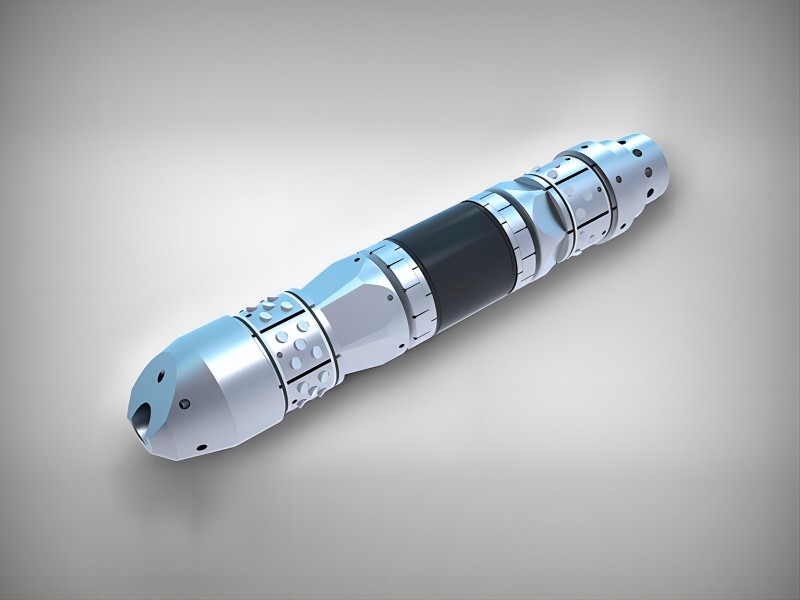

To ensure product stability and control under actual field conditions, we carried out a comprehensive experimental test on our single-slip elastomer dissolvable frac plug.

Below is a detailed overview of the testing procedure and key results. Let’s take a closer look.

1. Experimental Preparation

To ensure safety and data accuracy throughout the testing process, a dedicated explosion-proof test bay was set up and equipped with the following essential devices and materials:

- Liquid Storage Tank: Used for preparing high-salinity solutions

- Electronic Scale: For precise measurement of the frac plug and any remaining residues

- Measuring Cup: To control the volume of reagents and liquids

- Casing Model: Inner diameter of 114 mm, steel grade TP140

- KCl Solution: Used to simulate downhole salinity levels (up to 60,000 PPM)

Before testing, we measured outer diameter of the frac plug (maximum OD: 102 mm) to ensure compatibility with the test casing.

①Liquid Storage Tank ② Electronic Scale ③ Measuring Cup ④ Casing ⑤ KCI

Explosion-proof Test Bay

Frac Plug Dimension Measurement

Experimental Test Requirements:

- Test Temperature: 120 ℃

- Test Pressure Difference:70 Mpa

- Pressure Holding Time: 24 H

- Salinity: 60,000 PPM

- Max. OD of Frac Plug: 102 mm

- Casing Inner Diameter: 114 mm

- Casing Grade: TP140

2. Frac Plug Setting Test

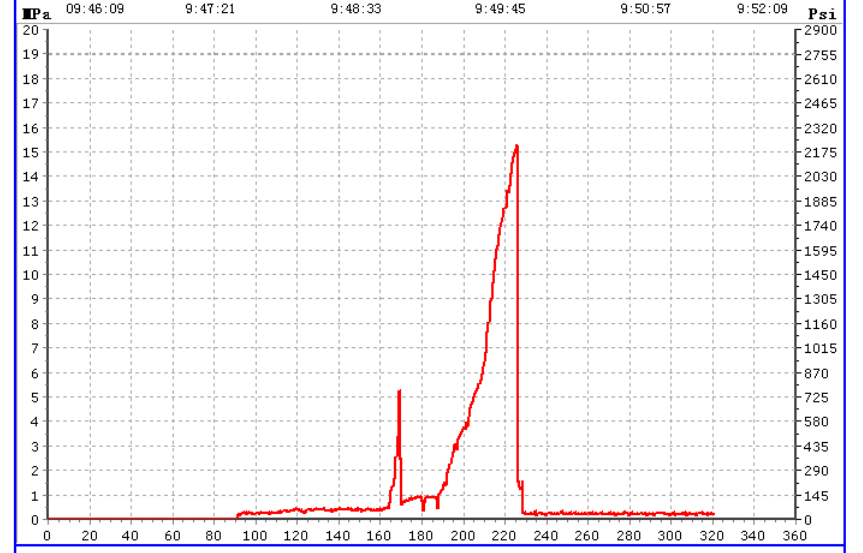

After preparing all necessary equipment and materials, we proceeded with the frac plug setting test. This phase aimed to simulate the actual downhole setting process and evaluate the structural stability and setting reliability of the plug.

Using a pressure-displacement sensing system, we captured and recorded the complete setting curve. The test results demonstrated that the frac plug could deploy smoothly, firmly contact the inner wall of the casing, and secure anchoring, demonstrating its excellent setting response and mechanical performance.

Setting Curve

3. Normal-Temperature Sealing Performance Test

Next, we conducted a sealing performance test under normal temperature conditions:

- Test Pressures: 50 MPa and 70 MPa

- Pressure Holding Time: 15 minutes for each pressure level

- Observation: Monitoring for any leakage around the frac plug

| Normal-temperature Sealing Data table | ||

| Pressure:MPa | 50 | 70 |

| Pressure value at 15 minutes: MPa | 50 | 70 |

| Observe leakage condition | 49 | 70 |

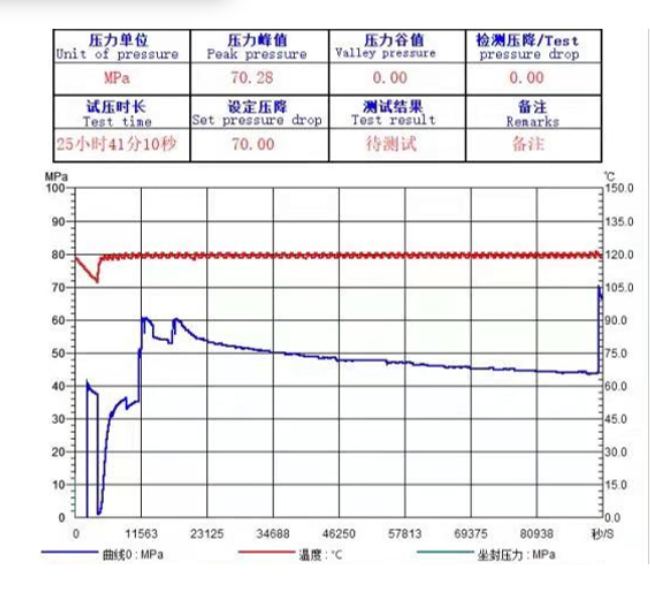

4. High-Temperature Sealing Performance Test

After testing under normal temperature conditions, the frac plug was placed in a high-temperature environment at 120 °C, subjected to a pressure of 70 MPa, and maintained for 24 hours.

During the test, the frac plug showed no structural abnormalities or pressure leakage, confirming its long-term stable sealing performance in downhole high-temperature fracturing environments.

5. Dissolution Performance Test (High-Temperature, High-Salinity Environment)

To simulate the natural degradation process of the frac plug downhole, we conducted a continuous dissolution test over 4 days in a 100 °C environment using a highly mineralized KCl solution with a salinity of 60,000 PPM.

Initial Weight: 2250 grams

Dissolution Time Points: 0, 24, 48, 72, and 96 hours

| Dissolution Temperature(℃) | 100℃ | Cl-% | 60,000PPM |

| Initial Weight(g) | 2250g |

| Dissolution Time(Hour) | 0 | 24 | 48 | 72 | 96 |

| Residual Weight(g) | 2250g | 1100g | 408g | 71.8g | 0kg |

Initial State of Frac Plug

24-hour Test

48-hour Test

72-hour Test

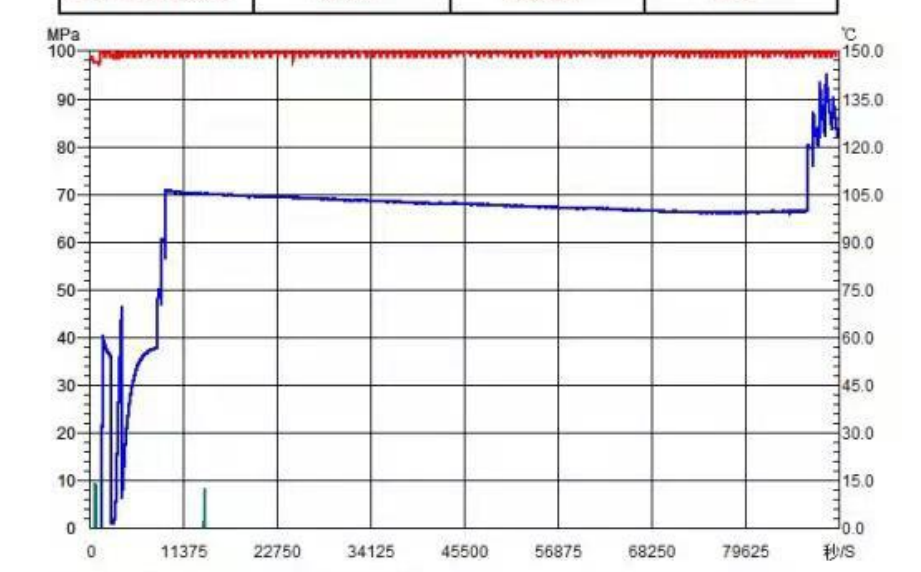

6. High-Temperature Pressure Bearing Test

Subsequently, the frac plug was subjected to continuous high pressure of 70.28 MPa in a 120 °C high-temperature environment to simulate the actual downhole conditions during high-pressure fracturing operations. The pressure was maintained for 25 hours and 41 minutes.

During the test, the frac plug showed no deformation, cracking, or sealing failure, demonstrating its excellent structural load-bearing capacity.

7. Dissolution Experiment of Dissolvable Frac Plug(20000PPM, 120℃)

We further evaluated the dissolution performance of the frac plug in a solution with a salinity of 20,000 PPM to assess its degradation ability under varying field salinity conditions. The test results showed that although the dissolution rate slowed slightly, the material continued to degrade steadily, demonstrating good environmental adaptability and controllability. This provides technical support for use across diverse geological conditions.

8. Dissolvable Frac Plug in Construction Site and Decomposition Observation

This model of dissolvable frac plug has been deployed in an actual fracturing operation at an oil and gas well site. Following deployment, the plug successfully completed the setting and multiple-stage fracturing tasks without issues.

After 20 days, on-site observations were conducted with downhole video inspection and sampling. Confirmations were made that the frac plug had fully degraded with no residual solids detected, which ensured there were no obstacles to subsequent well cleanup operations.

The Photos of 20 Days after Decomposition

The entire operation process, including the downhole images, was thoroughly documented and archived as solid proof of product reliability and effectiveness under actual field conditions.

The photos of on-site operation

Summary and Technical Outlook

This series of tests comprehensively verified the core performance of Wingoil’s dissolvable frac plug:

- Smooth and reliable setting process

- Leak-free sealing under high-temperature and high-pressure conditions

- Rapid and controllable dissolution (within 96 hours)

- Adaptability to varying salinity environments

- Successful field application with complete degradation

Successful field testing of Wingoil’s dissolvable frac plug verifies its tremendous advantages in saving operation time, reducing risks, and improving efficiency. It is ideally designed for use in conventional horizontal wells, long-stage completions, and multi-stage fracturing operations under different conditions.

If you are looking for reliable dissolvable frac plug, Wingoil is definitely your trustworthy choice!