How to Dissolve a Frac Ball? – Solved

In modern oil and gas multi-stage fracturing operations, frac balls play a critical role by temporarily isolating specific stages and directing the fracturing sequence. However, as the number of stages increases, well depths grow, and reservoir conditions become more complex, whether a frac ball can dissolve as expected directly affects wellbore clean-up efficiency, production recovery speed, and overall operational cost.

Today, we will provide a comprehensive answer to the common industry question: “How to dissolve a frac ball?” It also offers an in-depth introduction to the latest dissolvable frac ball technologies, helping you optimize fracturing performance, minimize unnecessary milling operations, and reduce operational expenses.

Part 1. Why Must a Frac Ball Dissolve?

Frac balls serve several essential functions during multi-stage fracturing:

- Temporarily isolate specific well sections

- Direct fracturing fluid into targeted reservoir zones

- Control the fracturing sequence and pumping rate

Once the fracturing operation is completed, the frac ball must be removed or dissolved. If it fails to dissolve properly, several issues may arise:

- Wellbore blockage, preventing the well from flowing normally

- Additional coiled tubing milling, which is costly, time-consuming, and introduces operational risks

- Incomplete removal of stage plugs, reducing reservoir connectivity and overall production

- Longer intervention time and higher safety risks

Therefore, having frac balls with controlled and predictable dissolvability is crucial in modern fracturing operations to ensure smooth post-frac clean-up and efficient production recovery.

Part 2. Types of Frac Balls and Their Dissolution Mechanisms

1. Composite Frac Balls

Composite frac balls have been widely used in early multi-stage fracturing systems. They are typically made from resin-based composites or fiber-reinforced materials.

Key characteristics:

- Non-dissolvable by nature — the material does not react with downhole fluids.

- Require milling for removal, usually via coiled tubing.

- Milling increases operational time and introduces risks such as tool sticking or incomplete debris cleanout.

- Because they cannot dissolve on their own, composite balls are becoming less favorable in deeper or high-stage-count wells.

2. Metallic Frac Balls (Aluminum & Magnesium Alloys)

Metallic frac balls can exhibit partial dissolvability depending on their alloy composition and downhole environment.

Their dissolution behavior depends on:

- Temperature — higher temperatures accelerate corrosion and reaction rates.

- Salinity and fluid composition — high-salinity brines promote dissolution for Mg-based alloys.

- Material reactivity — different alloy formulations determine the dissolution speed.

- In high-temperature or high-salinity wells, metallic balls dissolve more effectively, reducing—but not eliminating—the need for intervention.

3. Dissolvable Frac Balls

Dissolvable frac balls represent the most advanced and cost-efficient solution currently available. These balls are made from engineered dissolvable metals (such as high-reactivity magnesium alloys) or dissolvable polymers, designed to automatically degrade under specific downhole conditions.

Core advantages include:

- Fully automatic dissolution, eliminating milling entirely

- Predictable dissolution time, engineered according to well temperature, fluid chemistry, and operational requirements

- High compatibility with extreme conditions, including high pressure, high temperature, and high salinity

- Reduced operational risks, shorter intervention time, and significantly lower overall cost

As unconventional oil and gas wells continue to increase in complexity and stage counts, dissolvable frac balls are rapidly becoming the mainstream choice for efficient and low-risk fracturing operations.

Part 3. How Does a Frac Ball Dissolve?

To answer “how to dissolve a frac ball”, you need to understand the variables that control frac ball dissolution rate and completeness. Below are the primary influencing factors and how each affects dissolvability:

- Temperature

Temperature is the single most important control on chemical reaction rates.

Higher downhole temperatures accelerate dissolution, so deep, hot wells typically see faster breakdown of dissolvable materials.

Different dissolvable materials are engineered for different temperature windows — selecting a material matched to the expected well temperature is essential for predictable timing.

- Salinity / Fluid Mineralization

Many dissolvable metals and polymers dissolve via electrochemical or hydrolytic mechanisms that depend on ionic strength.

Higher salinity (greater mineral content) generally increases dissolution rate, because ions in the fluid facilitate corrosion/electrochemical reactions.

Designing a dissolution profile often requires knowledge of formation and fracture fluid salinity to predict when the ball will disappear.

- Flow and Pressure Conditions

Liquid flow across the ball’s surface promotes mechanical erosion and removes reaction products, both of which speed overall dissolution.

Pressure differentials and transient flows during operations (e.g., post-frac cleanup flows) can significantly influence how quickly a ball degrades.

Stagnant zones or low-flow segments may experience markedly slower dissolution.

- Material Composition

The base material and alloy/formulation determine inherent reactivity: for example, magnesium-based dissolvable metals are highly reactive, while some engineered polymers dissolve by hydrolysis.

Additives and composite structures (e.g., fiber reinforcements, corrosion inhibitors, or porogens) are used to tailor initial strength, collapse behavior, and dissolution kinetics.

Proper matching of mechanical strength (to survive pumping) and reactivity (to dissolve on schedule) is the core materials engineering challenge.

- Downhole Environmental Variability

Real wells seldom match laboratory conditions: temperature gradients, variable salinity between stages, and fluctuating pressure/flow can all introduce deviations from predicted dissolution times.

Heterogeneous fluids, unexpected brine pockets, or differential heating can cause some balls to dissolve sooner or later than designed.

Therefore, selecting dissolvable balls with robust, well-characterized performance across plausible environmental ranges reduces operational uncertainty.

Part 4. Common Reasons a Frac Ball Fails to Dissolve

If a frac ball does not dissolve as expected, the usual causes include:

- Insufficient downhole temperature — reaction rates slow at lower temperatures.

- Low salinity / inadequate mineralization — ionic strength too low to drive electrochemical or hydrolytic dissolution.

- Material mismatched to local conditions — the ball’s formulation isn’t suitable for the well’s temperature, chemistry, or pressure.

- Ball deformation from mechanical stress — crushed or deformed balls can get lodged and shield reactive surfaces.

- Use of non-dissolvable materials — composite or conventional metallic balls that aren’t engineered to dissolve.

- Lack of pressure/flow cycling in the interval — stagnant conditions impede removal of reaction products and slow dissolution.

These failure modes are a major reason dissolvable frac balls have rapidly gained adoption in modern fracturing operations.

Part 5. Solutions When a Frac Ball Won’t Dissolve

When dissolution is slower than planned, operators can consider these mitigation steps:

Increase downhole temperature (if operationally feasible) — e.g., by adjusting fluid temperatures or delaying until thermal equilibration.

Enhance fluid circulation and flow rates — increased flow promotes surface erosion and removes corrosion products.

Introduce salts or chemical accelerants — compatible additives can raise ionic strength or catalyze hydrolysis (must be vetted for formation compatibility).

Switch to a higher-reactivity dissolvable material — select a formulation engineered for faster breakdown in the well’s conditions.

Mechanical intervention as last resort — coiled-tubing milling or spot milling if dissolution fails, though it increases cost and risk.

Best long-term approach: use a proven dissolvable frac ball — choosing a ball with well-characterized performance across the expected temperature, salinity, and flow ranges minimizes the chance of non-dissolution and reduces the need for intervention.

Choosing materials and operational parameters that match the well’s real conditions is the most effective way to avoid non-dissolution and the costs associated with milling interventions.

Part 6. Why Dissolvable Frac Balls Are the Optimal Solution?

Compared to conventional frac balls, dissolvable frac balls offer unmatched advantages:

- Fully automatic dissolution, requiring no manual intervention

- Reduce milling costs by over 80%

- Safer and more efficient stage isolation during fracturing

- Compatible with multi-stage fracturing, deep wells, and long horizontal laterals

- Minimized risk of ball sticking, ensuring higher fracturing success rates

For operators and oil companies aiming to maximize efficiency and lower operational costs, dissolvable frac balls provide the highest return on investment (ROI).

Part 7. Wingoil Dissolvable Frac Ball: Why Its Your Best Choice?

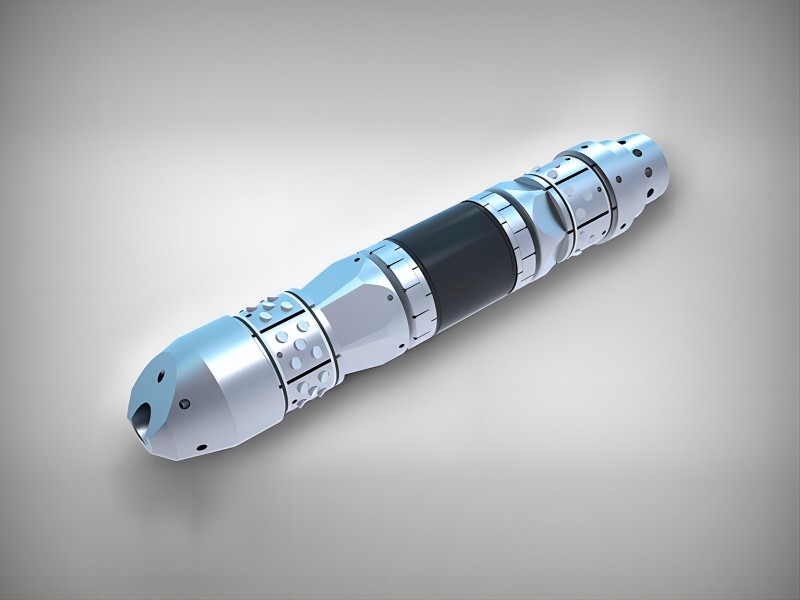

Wingoil Dissolvable Frac Ball is made from dissolvable magnesium alloy with a protective coating, designed to withstand extreme downhole pressures and temperatures while providing reliable stage isolation. After fracturing, it dissolves automatically, eliminating costly and time-consuming milling operations.

Key Features and Advantages:

Controlled Acid Resistance: Lab tests at 70°C in 20% HCl solution show the coating remains intact within 24 hours. Small corrosion holes appear 24–48 hours, gaps enlarge 48–60 hours, and deepen by 60–72 hours, ensuring predictable dissolution timing.

Durable yet Dissolvable: Magnesium-aluminum alloy provides mechanical strength for placement, while the coating delays corrosion until the desired time.

Eliminates Milling Operations: Automatic dissolution reduces operational costs and downtime.

Adaptable to Extreme Conditions: Suitable for high pressure, high temperature, high salinity, deep wells, long horizontals, and multi-stage fracturing.

Reliable Stage Isolation: Strength, coating, and controlled dissolution minimize sticking risk and improve fracturing efficiency.

In short, Wingoil Dissolvable Frac Balls combine mechanical reliability, predictable dissolvability, and operational safety, offering a cost-effective solution for modern fracturing operations.

Final Thoughts

Understanding how to dissolve a frac ball is key to improving fracturing success, minimizing milling operations, and reducing operational costs.

With the advancement of dissolvable material technology, Dissolvable Frac Balls have become the most reliable, efficient, and cost-effective solution for stage isolation in fracturing operations.

If you are looking for a safer, more stable, and controllable dissolvable frac ball solution, Wingoil provides proven products and professional support. Contact us today to learn more.