Multiphase Pump Oil and Gas: How It Improve Fluid Transfer?

In the current oil and gas industry, transporting oil, gas, and water in three-phase flow has always been a huge issue during the production process. With conventional transportation, the oil, gas, and water are generally separated initially, and single-phase pumps are utilized to transport each phase independently.

This not only saves the investment in equipment and maintenance costs but also occupies much space. Multiphase pump oil and gas have been designed as an efficient and reliable system, which can transport water, gas, and oil in a simultaneous and non-separation mode.

Part 1. What is a Multiphase Pump?

A multiphase pump is a specialized pump with the capability to handle a mixture of water, oil, and gas without preprocessing. On the basis of their design principles, multiphase pumps are mainly divided into progressive cavity (screw) multiphase pumps and centrifugal multiphase pumps.

Multiphase pumps, unlike conventional single-phase pumps, not only prevent the need for intermediate separation gear but also deliver constant flow rates and react well to well production changes.

Part 2. How Multiphase Pumps Can Help in the Oil and Gas Industry?

Multiphase pumps are vital to modern oil and gas production since they transport oil, gas, and water combinations effectively. Multiphase pumps help the operators improve production efficiency, conserve infrastructure investment, extend well life, and react to dynamic field conditions, thus making them a key component of onshore and offshore production.

Successful Transportation of Unseparated Fluids

Multiphase pumps may pump a mixture of gas, oil, and water in a single pass without pre-treatment separation. This reduces tremendous amounts of complexity and space in the oilfield facilities and reduces both equipment investment and maintenance expenses.

In offshore platforms or remote onshore oilfields, where the accessibility and space are restricted, this benefit is particularly valuable. With the removal of intermediate separation steps, operators can streamline the process of production and attain smoother fluid handling.

Improved Production Efficiency

In oil and gas production, gas-liquid ratio in wells can vary. With constant flow under variable gas-liquid conditions, multiphase pumps assist in continuous production and minimizing losses from equipment downtime or varying flow rates.

It is particularly beneficial for marginal wells or highly fluctuating oilfields to allow operators to sustain production and maximize overall field performance.

Reduced Infrastructure Costs

Use of multiphase pumps minimizes reliance on single-phase pumps, separators, and other pipelines, thus simplifying system design. In long-distance transportation need or areas in tough terrain, multiphase pumps can save capital expenditure (CAPEX) in addition to operating expenditure (OPEX) substantially. Not just that, it improves project economics and increases oilfield infrastructure layout and operation efficiency.

Extended Well Life

Multiphase pumps can process high gas-liquid ratio blends, enabling marginal or decreasing wells to economically produce comparatively high rates. In enabling continuous production, the pumps are used for extending the economic well lives, thereby helping in enhanced overall oilfield capacity and profitability. This makes multiphase pumping a strategic choice for maximizing recovery from mature oilfields.

Flexible Adaptation to Several Operating Conditions

Multiphase pumps are flexible to both offshore and onshore oilfields, including those with limited space or extreme conditions. They are able to handle fluctuating mixture composition and flow rates, adapting to the dynamics of well production.

Offering superior reliability and operating flexibility, multiphase pumps ensure stable operation across a broad spectrum of field conditions, making them an all-around choice for today’s oil and gas production.

Part 3. Applications of Multiphase Pumps in the Oil and Gas Industry

Multiphase pumps play a crucial role in the oil and gas industry, transporting oils, gases, and water with high efficiency. They are adaptable and are able to handle a variety of challenging applications, from transporting at the end-of-well to offshore platforms, thus facilitating operators to optimize production efficiency, reduce costs, and minimize infrastructure.

End-of-Well Oilfield Transportation

Multiphase pumps can pump unseparated fluids directly from the wellhead to production and transmission pipelines. This minimizes the need for midstream separation facilities, simplifies production process, and reduces capital and operating costs.

Raised Production in Marginal Oilfields

For aging wells or unstable oilfields with varying production, multiphase pumps provide effective production by allowing varying flow rates as well as varying gas-liquid ratios. This produces a stable output and enhances the productive life of the oilfield.

Pipeline Transportation Systems

Multiphase pumps excel in conveying an oil-gas-water continuum across considerable distances by partially or wholly dispensing with separate degassing and dewatering units along the pipeline. This capability simplifies the architecture of the transport system, diminishes the frequency of mechanical upkeep, and, crucially, stabilizes hydraulic continuity and mechanical loading within the pipeline.

Offshore Oil Platforms

The constrained accommodation space typical of offshore platforms, compounded by the corrosive and dynamically variable environment, renders the application of multiphase pumps highly beneficial. It lowers the cumulative cost of mechanical servicing, and are engineered for persistent performance under severe marine conditions, with a capacity to track fluid compositional and pressure excursions.

Part 4. How to Choose the Right Multiphase Pump?

Choosing the right multiphase pump demands keen consideration of various aspects in order to achieve best performance, reliability, and cost-effectiveness in oil and gas operations. Some of the key considerations are:

Flow Rate and Pressure Requirements

The pump must be capable of handling the greatest expected production from the field or well. Measurement of peak and average flow rates and discharge pressure required aids in maintaining the pump stable under varying production conditions without overloading.

Fluid Composition

Understanding the fluid composition of oil, water, and gas is crucial in selecting the optimum pump type. Centrifugal multiphase pumps would generally suit the condition of high flow and low gas-liquid ratio, while progressive cavity (screw) pumps would better perform in high gas content wells or variable gas-liquid ratio wells. Analysis of fluid composition correctly prevents issues such as gas locking or cavitation.

Operating Environment

Environmental conditions, including temperature, altitude, and offshore or onshore installation, influence the choice of materials and protection levels. Offshore platform pumps may require materials resistant to corrosion, higher protection ratings, and streamlined design to accommodate restricted space and harsh marine conditions.

Reliability and Maintenance Costs

Long-term reliability operation and maintenance ease are of prime importance. Selection of pumps based on proven reliability, availability of spare parts, and ease of maintenance is critical. Minimizing downtime and ease of maintenance helps ensure low operating costs and uninterrupted production.

Supplier Expertise and OEM Solutions

Choosing a good supplier or OEM vendor can become a performance-determining and after-sales-support-issue. Experienced manufacturers are able to offer bespoke solutions to accommodate specific well conditions, technical support, and assured installation and commissioning.

Part 5. Recommended: Wingoil Hydraulic Multiphase Transfer Pump System

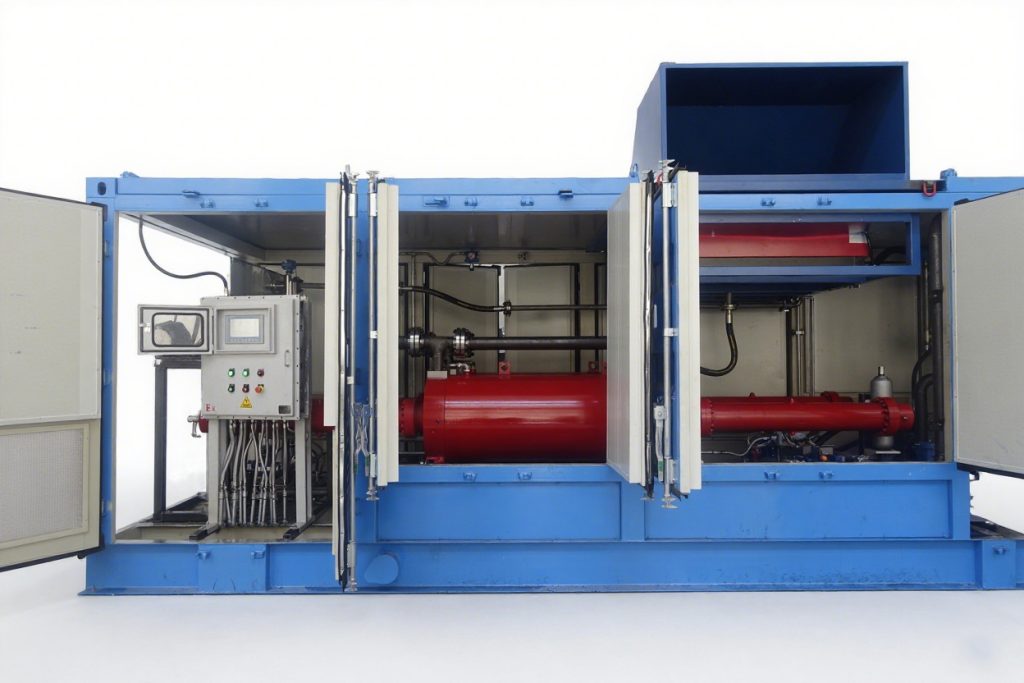

Wingoil Hydraulic Multiphase Transfer Pump System is an intelligent and very efficient oil and gas boost and compression system consisting of an intelligent hydraulic system, multiphase pump, and optional electric or gas-fueled generator (with optional gas-lift device). The system can transport and produce mixtures of oil, gas, water, and trace amounts of solids without a three-phase separator, which is ideal for gas wells and mixed oil-gas wells.

Key Specifications and Benefits:

Reduced Wellhead Pressure and Increased Production: The system has the capability to significantly lower the wellhead pressure of gas wells or well groups, increasing oil and gas production as well as the production cycle.

Concurrent Transportation Without Three-Phase Separation: The multiphase pump inlet can be directly connected to pipes without suffering a pressure loss of approximately 0.2 MPa caused by three-phase separation.

Energy Saving: Under the same conditions of gas production and pressure difference, the power consumption is approximately 50% of traditional pumps.

Intelligent Automated Control: The hydraulic station system employs PLC control and intelligent, explosion-proof, and convenient maintenance operation with remote monitoring support.

Compact Structure for Easy Transportation and Installation: The skid-mounted type is convenient to transport and install, and several units can be mounted in series for increased pressure or in parallel for increased flow rate.

Application of Self-Produced Gas as Gas-Lift Fluid: Saves on the costs of gas lift while conserving plenty of energy.

The system can be applied not only to single-well gas lift but also multi-well circulation gas lift operations, giving oil and gas companies a most efficient, smart, and cost-saving solution.

Summary

Multiphase pumps are increasingly playing a crucial role in the oil and gas industry. Multiphase pumps boost the efficiency of unseparated fluid transportation, enhance production efficiency in the oilfield, reduce infrastructure costs, and improve productive well life.

For companies seeking new oilfield management strategies, multiphase pumps are a critical piece of equipment. If you are looking for reliable multiphase pumps, Wingoil can be your trustworthy choice!