1. What problems are there conventional gas wells and shale gas wells in their mid-to-late production stages?

Through extensive field visits and research across domestic oil and gas fields, Chongqing Weiyun (Wingoil) has observed that conventional gas wells and shale gas wells in their mid-to-late production stages commonly face challenges such as low wellhead pressure, severe liquid and decreaced production. Thus after several years’ research and development, our company designed multiphase pumping system specialized for this kind of wells. Up to now, the equipment were successfully applied to many gas-oil well clusters and help increase the gas production.

2. CASE and SOLUTION

Case location: Yongchuan disctrict in Chongqing city

End user: Yongchuan Gas Production and Transportation Operation Site of Chongqing Gas Mine

Well No.: Huang Platform

2.1 BACKGROUND of Shale Gas Well of Huang Platform:

Huang Platform is one of the main shale gas production areas in the the West of Chongqing Area. The platform comprises four wells, namely Huang, which were successively put into production between October and November 2020. After over one year of production, each well gradually faces difficulties in carrying liquid. Measures such as gas-well deliquification by casing-tubing pressure equalization and foam drainage assistance were frequently employed, but these could only sustain short-term production. Subsequently, the wells were forced to shut off for pressure buildup as the tubing pressure increased to match the output pressure. Consequently, the gas production rate and liquid-carrying capacity of all wells on the platform were severely constrained.

In August 2022, Chongqing Gas Mine organized relevant units, including Chongqing WeiYun Technology Development Co., Ltd. and the Survey and Design Institute, for on-site meetings, specialized analysis, and in-depth argumentation. It was decided to adopt the oil and gas well multiphase pumping system with mixed gas-fluid production and transportation technology, and an implementation plan was formulated.

2.2 The designed parameters of Multiphase Pump

The model and parameter designed for Multiphase Pump

| Multiphase Pumping System Model | H500/140 | ||

| Main Parameters for Pump | Flow Rate Regulated Range | % | 25~100 |

| Flow Rate Regulated Mode | Variable frequency adjustment | ||

| Compressor suction temperature | ℃ | 25-40℃ | |

| Min. inlet pressure | MPa(G) | 0.15 (designed Pressure) | |

| Max. Outlet Pressure | MPa(G) | 6.3 | |

| Intellegent Hydraulic Station | Power Source | Motor | |

| Continuous Power / Speed | 75kW/1480rpm | ||

| Rated Frequency | 50Hz | ||

| Insulation Grade | F | ||

| Protection Level | IP54 | ||

| Explosion-proof Grade | Ex dⅡBT4 | ||

| Hydraulic Output Pressure | MPa(G) | 20 | |

| Flow Rate | L/min | 340 | |

| Cooling Mode | Mandatory Air Cooling | ||

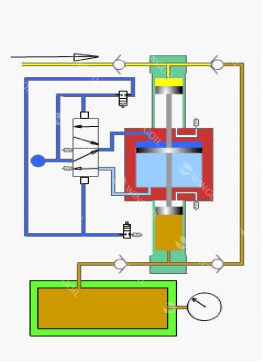

| Mounting Location | Multiphase Pumping System can be directly installed at the wellhead to handle, boost, and transport mixed gaseous, liquid, and minor fine solid components. | ||

2.3 Complete and Delivery of Multiphase Pump System

2.4 On-site Mounting of Multiphase Pumping System

The Oilfield Company Conducts an On-site Process Review

PC Monitoring on Multiphase Pumps Running

Mobile Monitoring on Multiphase Pumps Running

2.5 Trial Operation

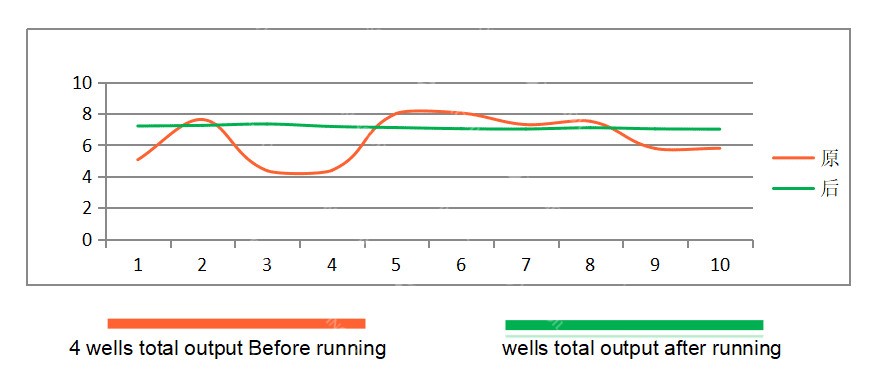

Wellhead Pressure ( Inlet Pressure ) Curve Chart

After 5 phases from preparation, equipment trial operation, each of the 4 wells operation, 4 wells simultaneously to formally production operation since Oct. 12th., 2022, the gas production increased and its data as below.

Production Increase Report

| Metric | Before Equipment Operation | After Equipment Operation | Change/Observation |

| Average Daily Production | 50,000 – 60,000 m³/day | 60,000 – 80,000 m³/day | Increase of 10,000 – 20,000 m³/day |

| Wellhead Pressure | Decreased by 0.3 – 0.8 MPa | Pessure differential increased |

After the mutiphase pumping system equipment is supplied with stable power, it is expected to further reduce the wellhead pressure, enhance liquid-carrying capacity, and increase production.

Conclusion: Operating at 45% power has achieved production increase and stabilization, and a further power boost can elevate output again.

2.6 The features of the Multiphase Pump:

- Linear motion

- No need lubrication

- No need separators at well head

- Multistage series and parallel connection

- Directly connect with wellhead

- Low speed running and low vibration

2.7 The Application Analysis of Multiphase Pumping On Sites

Technical Specification of Our Equipment: The technical roadmap of our equipment is centered on a booster plunger pump characterized by: (1) large diameter, (2) long stroke, and (3) low frequency.

This pump delivers a high suction force, enabling it to handle, boost, and transport 100% of the medium, whether in liquid, gaseous, or mixed-phase states.This core capability provides unique technical advantages in the following application scenarios:

1. Single-well Mixed-phase Transport: In many gas or oil wells, especially those without installed three-phase separators, reservoir energy declines, leading to reduced wellhead pressure. This makes long-distance transport challenging. Our pump meets the need for direct boosting and mixed-phase (oil, gas, water) transportat the wellhead, eliminating the prerequisite for pre-separation

2. Enhanced Liquid Carrying Capacity for Production Stabilization: When water production in oil or gas wells increases and the reservoir’s energy is insufficient to effectively carry the liquids to the surface, a liquid column builds up in the wellbore, restricting production and causing decline. This pump enhances the liquid-carrying capacity, helping to mitigate liquid loading and thereby maintain stable production

3. Inter-well Boosting on Production Platforms: On platforms with multiple wells, significant pressure differences between wells can cause some lower-pressure wells to be constrained or cease production. The high-displacement suctionof this pump can temporarily balance the pressuresacross multiple wells connected in parallel. This action releases downhole pressurein the lower-pressure wells, achieving the goals of production enhancement and dewatering