5 Essential Ways to Ensure Pipe Integrity Testing Success

In industries such as oil and gas, chemicals, power generation, and water treatment, pipelines serve as the core carriers for transporting fluids. However, over time, pipelines may face risks such as corrosion, cracks, and leaks. Without timely inspection and maintenance, these issues can at best reduce operational efficiency, and at worst, lead to major safety incidents.

Pipe integrity testing is the primary method of ensuring safe pipeline operation, fulfilling regulatory demands, and increasing service life.

In this article, we will outline in detail pipe integrity testing. The aim is to enable businesses to reach a greater level of pipeline management within intricate industrial settings.

Part 1. What is Pipe Integrity Testing?

Pipe integrity testing is a systematic process of establishing the physical condition of a pipeline, tightness of closure, and pressure-carrying capacity through the utilization of various technical techniques. Unlike common pipeline inspection, which is focused on surface checks, integrity testing consists of more scientific and comprehensive testing.

The level of testing typically includes leak detection, weld flaw detection, measurement of corrosive concentrations, and verification of maximum pressure limits. Advanced techniques such as non-destructive testing (NDT), hydrostatic or pneumatic pressure test, and smart monitoring systems are typically combined to create accurate results.

The ultimate goal of pipe integrity testing is to avoid accidents, meet industrial regulations, and have reduced long-term operating expenses and a greater safe service life for pipelines.

Part 2. Why Pipeline Testing is Important?

Pipelines are business vertical assets such as oil & gas, chemicals, power, and water treatment but are under adverse conditions, which contribute to deterioration over time. Pipe integrity testing plays a critical role in identifying hidden threats, regulatory compliance, and ensuring operations remain safe and cost-effective. The following are the main reasons why it is inevitable:

Ensuring Safety

Piping leakage or bursting can cause fire, explosion, or serious environmental pollution, and in extreme cases, result in casualties. Integrity testing helps identify hidden dangers such as corrosion, wall thinning, stress crack, and weld flaw at an early level.

With the identification of these issues before they become severe, operators are able to take control actions such as isolation, repair, or replacement, mitigating risks and safeguarding personnel, facilities, and the environment.

Industry Regulations and Standards Compliance

Oils & gas, chemicals, and power industries are governed by standards like API, ASME, and ISO, combined with local laws. Periodic integrity testing confirms compliance with these standards, supports audits and inspections, and provides documented evidence of pipeline safety. This not only reduces regulatory and legal liabilities but also improves company credibility and reputation.

Reducing Operational Expenses

Early detection and targeted maintenance avoid costly emergency shutdowns, overhaul repairs, or full pipeline replacement. By transitioning from reactive to predictive maintenance, organizations are able to schedule repairs more efficiently, optimize spare part management, reduce unplanned downtime, and lower lifecycle costs overall.

Extending Service Life and Optimizing Asset Management

Integrity testing provides data on corrosion rates, fatigue accumulation, and remaining strength. Operators can use this data to implement localized reinforcement, cathodic protection, or protective coatings to extend pipeline life. It also provides a scientific foundation for asset retirement decision-making, reinforcement, or upgrade, enabling smarter capital expenditure (CAPEX) spending.

Part 3. 5 Typical Pipe Integrity Testing Methods

Pipe integrity testing involves a variety of methods, with each well suited for application in various environments, pipeline material, and service conditions. Discussed below are five widely used techniques elaborated further:

1. Hydrostatic Testing

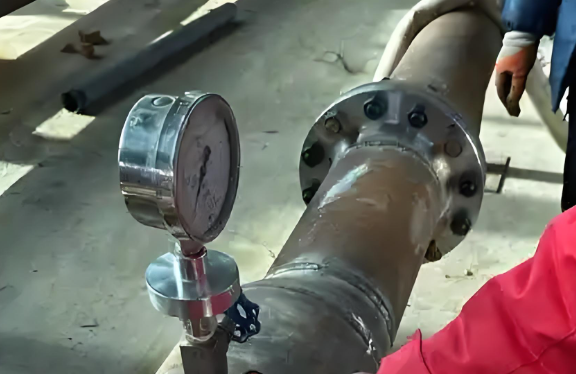

Hydrostatic testing is one of the oldest and most reliable methods of verifying pipeline integrity and leak tightness. In this process, the pipeline is filled with water and then pressurized to a pressure that is higher than its operating pressure. The examiners monitor for pressure drops, leakage, or structural failure to verify the system’s integrity.

- Typical Use: Primarily used in new pipes or pipes that have been extensively repaired.

- Advantages: Provides a direct measurement of the pressure-carrying capacity of a pipeline; ensures welds and piping material are stress-weldable.

- Limitations: Requires large amounts of water, which can be stressful in desert regions; water disposal after test must comply with environmental laws.

2. Pneumatic Testing

Pneumatic testing uses compressed air, nitrogen, or other inert gases instead of water to impose pressure on the pipeline. It is often used where the injection of water would cause contamination, freezing, or corrosion.

- Typical Use: Applied in dry, water-sensitive situations, or where draining and drying a system after hydro testing is not practical.

- Advantages: Less preparation and cleanup are necessary than with hydrostatic testing.

- Limitations: Because gases are compressible, an equipment failure during pneumatic testing releases much greater stored energy than in water, and explosion is more likely. Strictly controlled safeguards, including barricades and controlled pressurization, are required.

3. Ultrasonic Testing (UT)

Ultrasonic testing is a non-destructive technique using high-frequency sound waves to measure pipe wall thickness and detect corrosion or cracks. Hand-held UT devices allow inspectors to take point measurements in key positions along the pipeline.

- Typical Use: Most commonly used on operating pipelines to check the corrosion and wall thinning rate over time.

- Advantages: Non-invasive, accurate, and provides real-time data; can detect localized thinning that is not evident on the surface.

- Limitations: Requires specialized technicians; only at fixed points unless automated test equipment is employed.

4. Magnetic Particle & Radiographic Testing

Both the methods are used mainly for weld testing, a common weak link in pipelines.

Magnetic Particle Testing (MT): Includes magnetizing a section of the pipe and passing iron particles that accumulate at surface or near-surface imperfections, showing cracks or discontinuities.

Radiographic Testing (RT): Uses X-rays or gamma rays to create an image of the weld’s internal structure, so that it can detect porosity, slag inclusions, and other defects that cannot be seen with the naked eye.

- Typical Use: Required for weld integrity during construction and repair.

- Advantages: Highly sensitive to defects; provides permanent inspection records (in the case of RT).

- Limitations: MT is limited to ferromagnetic material; RT is costlier and involves the need for radiation protection controls and is time-consuming.

5. Smart Pigging (Intelligent Pigging)

Smart pigging employs pipeline inspection gauges (usually referred to as “pigs”) that are outfitted with advanced sensors such as magnetic flux leakage (MFL) or ultrasonic transducers. As the pig travels along the pipeline, it examines and records internal conditions continuously.

- Typical Use: Long-distance transmission pipelines in oil, gas, and water industries.

- Capabilities: Identifies corrosion, pitting, metal loss, cracking, weld flaw, and even deposition or blockage.

- Advantages: Provides comprehensive, full-line information for the entire pipeline; enables predictive maintenance and long-term integrity management.

- Limitations: Pipelines should be piggable (i.e., have launch and receive facilities); initial cost and operating costs are relatively high.

Part 4. Applications of Pipe Integrity Testing

Pipe integrity testing is widely applied across industries whose safe and reliable flow of fluids is of critical concern. Below is a more detailed description of its key applications:

1. Chemical Industry

Chemical plants tend to handle highly corrosive or hazardous chemicals such as acids, solvents, and reactive chemicals. Pipelines in such environments are prone to chemical attack, erosion, and stress corrosion cracking.

Periodicity of integrity test is required to prevent leaks, protect employees and the environment, and provide uninterrupted production. Methods like ultrasonic testing and radiographic weld inspection are commonly used for proper assessment.

2. Oil & Gas Industry

In the gas and oil sector, pipelines can stretch several hundred kilometers to transport crude oil, natural gas, and processed products. Breakage or leakage can result in catastrophic fires, environmental pollution, and significant financial losses.

Ongoing integrity testing—smart pigging, hydrostatic testing, and ultrasonic testing—facilitates ongoing safe operation, the early identification of corrosion or fissures, and compliance with high industry standards.

3. Water Treatment and Municipal Engineering

Water supply systems and sewage pipes are essential for public health and municipal infrastructure. Testing for integrity keeps the pipes leak-free and in good structural condition, avoiding contamination, outages, or widespread water loss. Hydrostatic testing and in-line inspection equipment are frequently employed to track aging infrastructure and enhance maintenance planning.

4. Power Generation Industry

High-pressure steam and cooling water piping in thermal, nuclear, and combined-cycle power plants operate under severe conditions. Integrity testing is necessary to guarantee safe operation and prevent accidents that would halt power generation. Regular inspections are conducted on high-pressure piping systems by methods such as ultrasonic thickness measurement, hydrostatic testing, and weld examination.

Pipe integrity testing is a requirement wherever fluid transportation under pressure exists. By detecting potential failures early, it does not just assure safety and compliance but also conserves downtime and maintenance expense in all industries.

Part 5. Pipe Integrity Testing Challenges

While indispensable, pipe integrity testing has a few challenges it has to deal with, rendering effective utilization tricky and expensive.

1. Complete Coverage of Long-Distance Pipelines

Long-distance pipelines, such as those in the petrochemical and gas sector, are usually several hundred or even thousands of kilometers long through mountainous and sparsely populated terrain.

Inspection and maintenance over such great distances may be logistically demanding, requiring sophisticated equipment and at times the use of mobile inspection teams or inline inspection units such as smart pigs. The sheer length of such systems makes it difficult to monitor in a thorough manner and to respond in a timely fashion.

2. Severe Operating Conditions

Pipes usually carry high-pressure, inflammable, or toxic media. Testing or inspection work in such conditions is risky, calling for stringent safety precautions and trained personnel.

For instance, pneumatic testing can be highly perilous due to the retained energy in compressed gases, and hydrostatic testing requires maximum caution while handling huge amounts of water to avert overpressure accidents. Safety considerations usually limit the rate and severity of testing.

3. Interpretation of Complex Data

Newly developed test techniques such as intelligent pigging and ultrasonic testing create huge volumes of data from hundreds of sensors. Proper interpretation requires advanced highly specialized skills and complex software tools.

Misinterpretation can lead to missed defects or unjustified maintenance, placing technical challenges upon companies with no in-house expertise.

4. Cost and Time Limitations

Long or high-pressure pipelines require extensive integrity testing, which is time-consuming and expensive. Hydrostatic or smart pigging tests require temporary shutdowns of production, impacting schedule and leading to potential lost revenue.

In addition to this, mobilizing men and equipment for remote inspection adds to the total expense. Merging exhaustive testing with operations efficiency remains a strong challenge for pipeline companies.

Part 6. How Wingoil Can Support Pipe Integrity Testing?

As an expert testing equipment and total solution supplier, Wingoil Diesel Engined Air Compressor Pipe Pressure Testing Equipment helps companies to provide the reliability, safety, and conformity of their pipeline network.

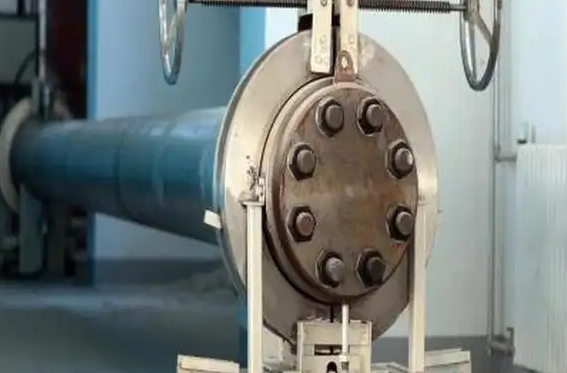

Its pipe pressure test equipment uses a heavy-duty diesel engine powering a screw air compressor to generate high-pressure airflow for efficient pipeline testing. Its diesel-driven skid integrates a diesel engine, air compressor, gas storage tank, and gas source treatment device, making it most appropriate for areas where external power supply is limited.

Key features are:

- Stable flow output rate for consistent test results

- Portable frame construction for simple transport and hoisting

- Multi-outlet output, suitable for testing multiple pipelines or pipeline sections simultaneously

- Closed-loop system, releasing pressure automatically and conserving energy

Summary

Pipe Integrity Testing is an integral part of industrial pipeline safety management. Not only does it affect working efficiency and regulatory compliance but also plays a considerable role in protecting the environment and personnel safety.

The right kind of testing techniques and capitalizing on superior technology and reliable equipment is required to ensure long-term pipeline safe operations.

For professional pipe integrity testing solutions, contact Wingoil for more information and technical support.