How to Choose Pressure Testing Equipment for Pipes?

The pressure test is an indispensable procedure for ensuring the safety, tightness, and reliability of pipeline systems in the fields of oil & gas, municipal water systems, fire protection engineering, HVAC piping, and industrial manufacturing. In each corresponding application, proper pressure testing equipment for pipes is key to performing high-quality pressure tests.

This article covers the types of pressure testing equipment, working principles, industries in which they are used, key selection criteria, and common troubleshooting solutions, all to make the right choice. Continue reading!

Part 1. What is Pressure Testing Equipment for Pipes?

Pressure testing equipment is a special device used to generate liquid or gas pressure applied on the pipeline system in order to inspect its strength, tightness, and capability of bearing pressure.

It is used in the following instances:

- Acceptance testing after new pipeline installation

- Inspection following repair or maintenance

- Factory production quality control (QC/QA)

- Verification of safety before industrial operation

The common kinds of pressure testing include:

- Hydrostatic Test: uses water as the test medium

- Pneumatic Test: This test uses air or nitrogen as the testing medium.

The core functions of pressure testing equipment include pressurizing the system, sustaining pressure within it, monitoring changes in pressure, and detecting leaks or structural defects either visually or by using instrumentation.

Part 2. Principal Types of Pressure Testing Equipment for Pipes

Understanding these categories is an essential step before purchasing because different types of equipment have to be used in different application scenarios.

1. Pneumatic Pressure Testing Equipment

Pneumatic testers use air or nitrogen for pressurizing pipeline systems. They are ideal for systems that it is inconvenient or impossible to drain or fill the system with water. This procedure is very common in HVAC systems, in compressed air lines, and in small industrial piping.

Note: Because air is compressible and possesses potential energy, pneumatic testing is normally considered to be more hazardous than hydraulic testing and is almost exclusively used for low-pressure applications.

2. Hydrostatic Pressure Test Equipment

Hydrostatic pressure test equipment uses clean water or a water-based fluid as the medium of pressure. It is the most popular kind of pressure testing because of its very high level of safety: water is not compressible and possesses very low stored energy, which provides more stability and predictability for the process.

Hydrostatic testing finds its application in oil and gas pipelines, municipal water systems, heating networks, and other large industrial piping installations.

3. Hand-Operated Test Pumps

These pumps are manual, intended for small diameter piping, laboratory applications, and other minor on-site maintenance work. They are lightweight, inexpensive, and easily portable. Many models are still capable of pressures to 50–100 bar while being relatively compact and are, therefore, useful for many pressure-checking applications.

4. Electric or Hydraulic Pressure Test Machines

These machines are suitable for large-scale projects or factory production lines, enabling a higher automation rate, stable pressure output, and efficiency. They are ideal in situations where repeated or continuous testing, such as batch production, system commissioning, or high-volume quality control processes, is needed.

5. Digital Pressure Test Systems

Digital systems include, among other components, sensors, pressure transducers, and the ability to log data. Digital systems can maintain pressure automatically, record test curves, and report results. Such devices are essential to engineering projects in which documented and traceable test data is required by regulatory or compliance standards.

Part 3. Key Features to Consider When Picking Pressure Testing Equipment

Selection of the right equipment for pressure testing not only affects testing efficiency but also directly impacts project safety. The following are the most important criteria to evaluate before making a purchase.

1. Pressure Range

Different pipeline materials call for different pressure levels, and the same applies to the different application scenarios. Low-pressure equipment is applied for PVC and PPR pipes, while medium-pressure systems are usually adopted in HDPE pipelines.

Carbon steel and stainless-steel pipelines can fall in the medium to high-pressure range, while in some oil and gas applications, very high pressure above 100 bar can be required. The choice of appropriate pressure range ensures both accuracy and safety.

2. Pressurization Capacity and Efficiency

Your choice should reflect the scale and nature of the project. Manual pumps are normally used in small jobs or during occasional onsite maintenance, while electric or hydraulic pressure testing machines ensure much greater efficiency and consistency in an industrial environment with highly demanded pressure and large flow rates.

3. Pressure Gauge Accuracy and Monitoring System

Accuracy is indispensable in realizing valid test results. Class 1.0 and Class 1.6 are the two most widely used precisions required in most projects. When applications require detailed test data to be recorded for archiving, a digital monitor or electronic pressure logging system should be used, since it will provide stable readings and track data automatically.

4. Safety Design

Safety features are paramount, as pressure testing is rather risky. Some major precautionary measures comprise automatic relief valves, overpressure protection, and extra-sturdy high-pressure hoses. These prevent any instant breakdown during the test and reduce potential hazards.

5. Material Quality and Durability

The good build quality of the equipment directly entails longevity and good performance. Stainless steel pump bodies, valves resistant to corrosion, and high-strength seals ensure longevity, resistance to harsh environments, and multiple cycles of pressurization.

6. Automation and Data Recording Requirements

For major EPC projects, pipeline commissioning, or factory QA processes, equipment with automated pressurization, pressure-holding functions, and digital data recording can greatly enhance efficiency and regulatory compliance. Such systems provide traceable results required for formal acceptance and documentation.

Part 4. Pressure Testing Equipment: How to Use Them Properly for Pipes

Proper use of the pressure testing equipment will provide the exact result and is crucial for safety. This is a general process for most industries.

Step 1. Preparation

Ensure that the pipeline is free from debris before any test is undertaken, then seal both ends of the pipe with stoppers to avoid leakage and ensure correct pressure reading.

Also inspect valves, fittings and connections for tightness as well as condition issues to lower risks of equipment damage or test failure. Proper preparation can help avoid risks associated with equipment damage or test failure.

Step 2. Filling with Fluid or Gas

Hydrostatic testing in liquids involves a very careful filling of the pipeline, completely removing any trapped air because pockets of air will give wrong readings or can allow sudden spikes in pressure.

Pneumatic testing in gases shall be brought up gradually to avoid rapid changes in pressure that can damage the pipeline or attached equipment.

Step 3. Pressurization

Gradually increase the pressure up to the target level according to the specifications of the test. Do not suddenly or unnecessarily overload the system to avoid overstressing. A controlled rate of pressurization is crucial both from a safety point of view and for obtaining accuracy.

Step 4. Holding the Pressure

Once the set pressure is reached, hold it during the time given by the relevant standard, which may be between 10 to 60 minutes depending on the material and the type of system. During that period, continuously monitor the pressure for fluctuations in value.

Step 5. Check Your Results.

A point-to-point drop in pressure greater than expected indicates a possible leak. Perform a detailed visual examination of the pipeline, with particular emphasis on fittings, welds and valves. Defects uncovered must be repaired prior to placing the system in service or returning it to operation.

Part 5. Common Problems and Solutions When Using Pressure Testing Equipment

Even with proper preparation, pressure testing can experience problems. Understanding these common issues and their solutions will help ensure accurate and safe testing.

1. Unable to Reach Target Pressure

In many instances, this is due to leaks within the system, valves not fully closed, or loose connections. For this, carefully check for leakage at all sealing points, tighten all the fittings and connections, and finally, close all valves appropriately. The problem resolution often allows the desired pressure within the system to be achieved.

2. Pressure Drops During the Test

This usually means a drop in pressure is being experienced and that there could be a leak somewhere within the system. Common areas to review are welds, flanges, and valve components for leaks. Any leaks should be found and repaired before the system is retested to avoid failure of the system or safety hazards.

3. Inadequate Pressure from Machinery

If such pressure cannot be achieved, it could be due to a faulty pump or an inadequate pressure rating of the unit for the purpose. The remedy is the repair or replacement of the pump, or using a testing device with increased pressure capability to meet the requirements within the system.

4. Fluctuating Pressure Gauge Readings

Uncalibrated gauges or gauge vibrations could lead to fluctuating readings. Recalibration of the pressure gauge is done to manufacturer instructions, or an instrument that has been correctly calibrated replaces it. Testing requires accurate measurement for reliability and compliance issues.

Wingoil Pressure Testing Equipment – Your Best Choice

Pressure testing equipment is indispensable in construction, production, and maintenance projects. Good equipment not only guarantees accurate and reliable test results but also greatly improves safety, reducing the probability of a leak or pipeline burst. From oil and gas, chemical, and construction industries to pipeline installation and industrial production lines, pressure testing is an indispensable process that has to be carried out efficiently and safely.

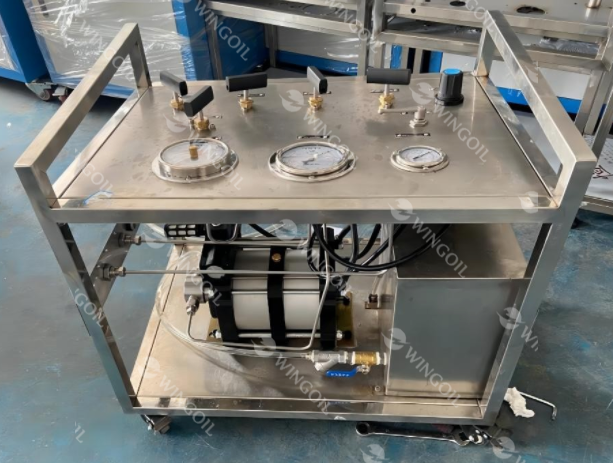

Among the choices available, Wingoil is characterized by low power consumption, high safety, stability, and durability. The device supports various power sources, and all the models are fitted with an automatic control system, as well as video remote monitoring. It provides a high flow rate and powerful, efficient high-pressure testing in operation. Without complicated operation, transportation can be easily conducted. Wingoil Pipeline Hoses-Valves-Testers ensure that all pressure tests on pipelines, hoses, instruments, or valves will be safe, accurate, and efficient.

Besides, Wingoil has vast experience in flow control and pressure testing with the focus on high- and ultra-high-pressure applications. It offers special solutions and on-site technical guidance according to clients’ requirements and helps the projects proceed smoothly. If choosing Wingoil, it means choosing reliability, safety, and professional pressure test expertise.