Problems

The shortcomings of pumping unit motor movement in actual use:

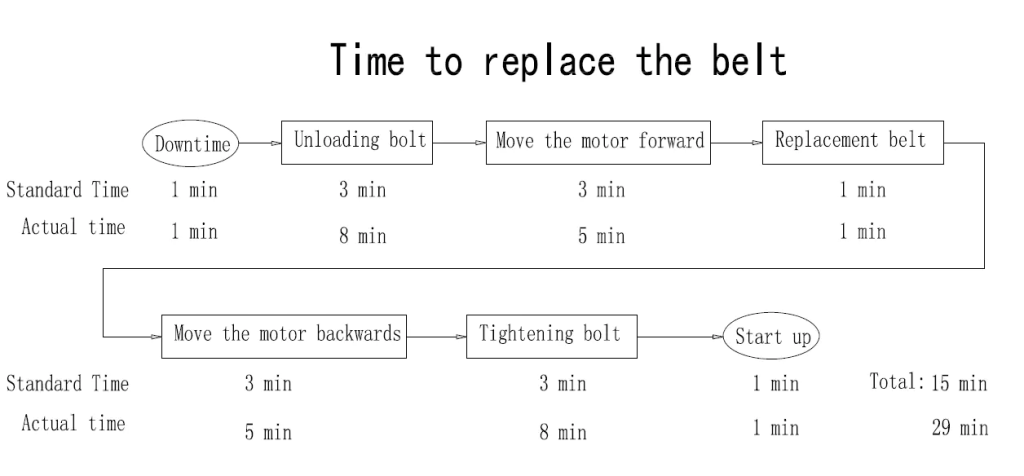

The pumping unit motor is the power equipment for the exploitation of crude oil. The belt transmits power to drive the pumping unit to operate and realize crude oil production. The belt runs continuously for 24 hours, wears faster, and the tightness needs to be adjusted to prolong the service life of the belt. Adjusting the tightness of the belt is a common operation of the oil producer. In the field adjustment, there are many preparation tools, the operation process is cumbersome, the time is long, the physical load is large, and the degree of tightness needs to be judged by human experience. This not only requires high qualification of the workers but also may cause the belt to slip or be too fatigued and broken. They are all security risks.

Find the reason

Motor rail installation is unreasonable

- The contact surface is large, so the required moving power is large;

- Poor orientation, “four alignments” is a heavy workload;

- The fixing method is unreasonable, and it takes time and effort to fix it.

The way of moving is unreasonable

- Many tools and complicated procedures;

- Limited moving distance;

- The tightness of the belt is not easy to control.

- Large workload and high labor intensity;

- Long working time and long downtime;

Propose a plan

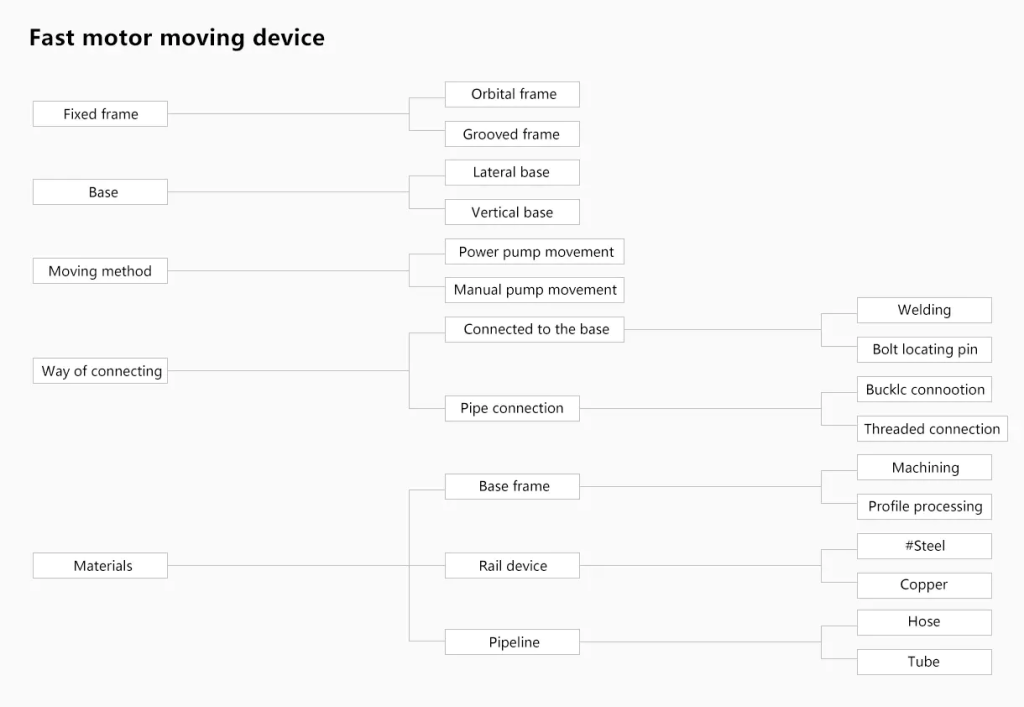

A mechanized device for rapidly moving the motor needs to be developed and it must have the characteristics of simple structure, convenient use, time-saving, labor-saving, safety, and, reliability.

Design principle:

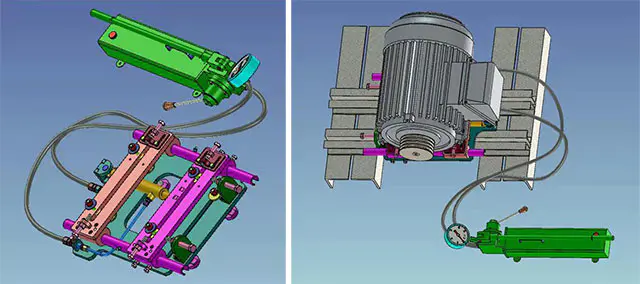

Manual hydraulics + jacks: Manual hydraulics provide power to the hydraulic cylinders, which push the motor mounts over the rails.

Final solutions

| Description | Technical solutions |

| Fixed frame | Forming ordinary plates, and locating the positioning holes of the motor slide rails. The motor base adopts a double slide type to move. |

| Motor base | The motor base takes care of both traverse and longitudinal movement. Traverse: waist hole + two side top wire structure. vertical movement: double track slide. |

| Mobile mode (power) | Hand pressure pump. |

| Connection method | Welding is combined with a threaded connection. The frame and the slide rail are connected and fixed by welding, and the slide rail and the split motor base are connected by positioning pin + bolt positioning. |

| Materials | 1. Ordinary steel galvanizing. 2. The pipeline is made of a pressure-resistant hose. |

| Others | 1. Secure the motor position with the rail set screws. 2. Use the top wire on both sides to adjust the motor position to ensure the motor is four aligned. 3. Use the front wire to ensure that the longitudinal position of the motor does not change under any circumstances. |

Products put into use on site

① Shortened the operation time;

② No downtime is required to ensure the operating rate of the well;

③ Reduce the labor intensity of oil workers;

④ Effectively avoid the occurrence of lying accidents;

⑤ The belt tension can be calculated according to the pressure gauge, and the adjustment is obvious and accurate.

⑥ No screw fixing, just move into the specified position to move the motor

⑦ Its good operability reduces the number of operators from the original 2-3 people to the current one.