Testing Device for Core Performance of Dissolvable Bridge Plug

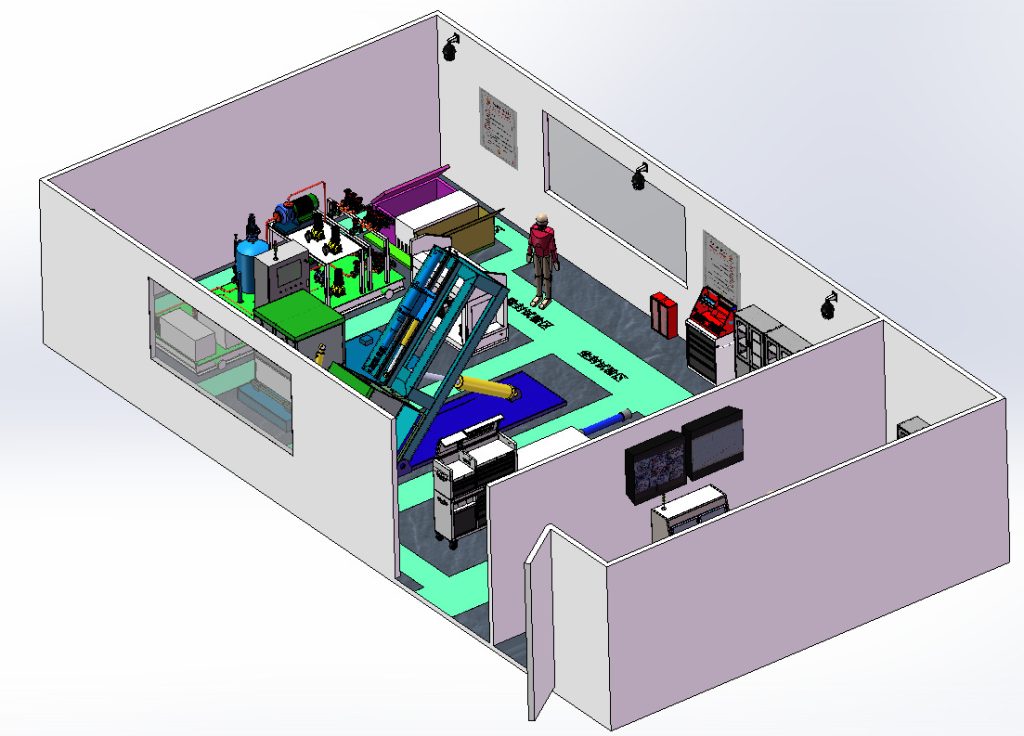

As a key temporary isolation tool in staged fracturing operations for oil and gas wells, the performance reliability of dissolvable bridge plugs directly determines construction safety and operational efficiency. To precisely control product quality, the dissolvable frac plug testing device was created by Chongqing Weiyun Technology Development Co., Ltd. This frac plug testing unit systematically verifies the core performance of the plug by simulating downhole actual conditions. Among the testing processes, the setting test, high-temperature & high-pressure seal verification test, and circulation dissolution test are the core tests. The distinct characteristics and verification objectives for each kind of test collectively build a quality assurance system for soluble frac plugs.

Setting Test

The core feature of the Setting Test is to simulate on-site setting working conditions to verify the reliability and stability of the bridge plug setting. The test is carried out by the operating the hydraulic setting system within the device. By precisely controlling the setting pressure and thrust to simulate the setting process after the plug is pumped into downhole. Key verification indicators include setting success rate, release reliability, and initial sealing performance after setting. During the test, the setting pressure curve is monitored to ensure the pressure meets design requirements (e.g., in some scenarios, the release pressure needs to stabilize around 17.8 MPa), while also verifying whether the plug’s anchoring structure is secure without risk of slippage after setting. On-site application data indicates that qualified plugs must achieve a setting success rate of over 99%, and can quickly form an effective isolation after setting, laying the foundation for subsequent fracturing operations.

High-Temperature & High-Pressure Seal Verification Test

The High-Temperature & High-Pressure Seal Verification Test focuses on simulating downhole extreme temperature and pressure environments to verify the pressure-bearing capacity and sealing durability of the plug. The test utilizes a high-temperature water pressure testing device combined with heating systems(electric blanket) to create temperature and pressure conditions matching the target formation. The temperature range covers from 30°C (ultra-low temperature conditions) to 150°C (ultra-high temperature conditions), with pressure up to 70 MPa. The test duration can be extended beyond 24 hours according to operational needs. The core function is to monitor the pressure drop change of the plug under sustained high temperature and pressure. The pressure drop is required to be within a reasonable range (e.g., not exceeding 2.3 MPa when stabilizing at 70 MPa for 15 minutes) during the stabilization period, while verifying that the plug’s sealing structure shows no deformation or leakage under extreme conditions. This test is particularly adapted to temperature and pressure differences across various formations, such as ultra-high temperature working conditions in Shengli Oilfield or ultra-low temperature conditions in Shanxi coalbed methane fields, ensuring the plug can maintain long-term stable pressure-bearing capacity in actual operational environments and avoid seal failure during fracturing processes.

Circulation Dissolution Test

The core function of the Circulation Dissolution Test is to simulate the downhole fluid environment to verify the controllability, thoroughness, and environmental adaptability of the plug dissolution. The test employs thermostatic water bath, circulation pipelines, and other apparatuses, using formation water or simulated mineralization degree solutions (e.g., 3%-7% KCl solution, water solution with chloride concentration of 0-30,000 mg/L) as the medium. It precisely controls the test temperature (25°C-200°C, matching different formation temperatures) and pressure conditions, simulating the downhole fluid flow state through circulating fluid to accelerate the dissolution process and simulate the flowback scenario of dissolution materials. Test data include dynamically monitoring the dissolution rate, recording the complete dissolution time, and analyzing the particle size and mass proportion of dissolution residues.

The key verified targets are that the plug must achieve controllable dissolution within the design period (48-120 hours for conventional conditions, extendable to 16 days for special scenarios), with the maximum particle size of dissolution residues not exceeding 10 mm, and the total mass proportion not exceeding 2.9%. Furthermore, the residues should be able to pass through a 4 mm filter screen and be discharged with the flowback fluid without clogging the wellbore or formation pores. Additionally, the test verifies the impact of different mineralization degrees and temperature conditions on the dissolution rate, ensuring the plug maintains stable dissolution performance even in special environments like high mineralization or extreme temperature zones.

In summary, the three major tests, through the coordinated operation of the device, form a full-chain performance verification logic: “Setting Reliability -> Withstanding Extreme Conditions -> Dissolution Completeness.” The test data not only supports the product researching and development of all-metal dissolvable bridge plugs, but also directly guides application selection on the product. This makes sure that verified plugs meet operational requirements throughout the entire process of pumping, setting, fracturing, and dissolution, ultimately achieving intervention-free full-bore production and reducing construction costs and risks