Application of Chemical Injection Skids in the Oil & Gas Industry

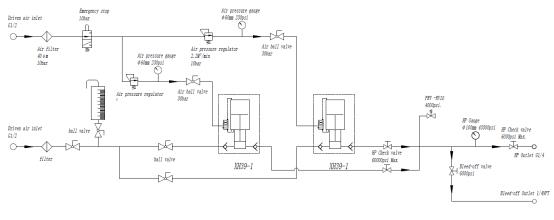

The chemical injection skid is a piece of equipment designed to inject chemicals into a system, as its name suggests. Typically, it is used to inject chemicals into a system at a specific pressure level.

Why use a chemical injection skid?

Chemical injections can operate continuously or sporadically. Additionally, it is employed by numerous marine and offshore businesses in numerous contexts and for a variety of objectives. This type of oil industry device will then be used by engineers to inject water into the reservoir.

This is done to raise the bar and boost output. The oil from the reservoir is also displaced or swept toward water injection wells using the chemical injection skid. Both onshore and offshore often contain those injection wells. Only 30% of the oil in a reservoir is extracted by humans in order to raise and sustain the pace of production over time.

There are chemical injection skids with high- and medium-pressure injection systems and packages. Additional chemical injection skids for upstream and downstream processes are available. Among other things, all of those are meant to improve oil recovery, enhance pipeline throughput, and thoroughly clean the oceans.

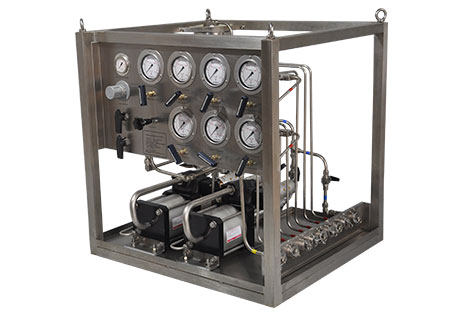

What are included in a chemical injection skid system?

A chemical injection skid system is made up of a variety of parts. Listed below are some of its essential parts.

Tanks

One of the most crucial parts of any chemical injection system are tanks. They have to store the substances that are put into the system, which is primarily why. Tank dimensions and construction may vary. However, they will typically be cylindrical and horizontal. With a flat or a hollow top, they may have a flat, conical, or hollow bottom.

Pumps

Another crucial component of the chemical injection system is the pump. The main reason for this is that they provide the source for creating the flow and pressure necessary to achieve the system’s goal. Pumps can have a diaphragm or plunger design and can be powered by an electric motor, air-operated motor, solar power motor, or solenoid-driven motor, among other options.

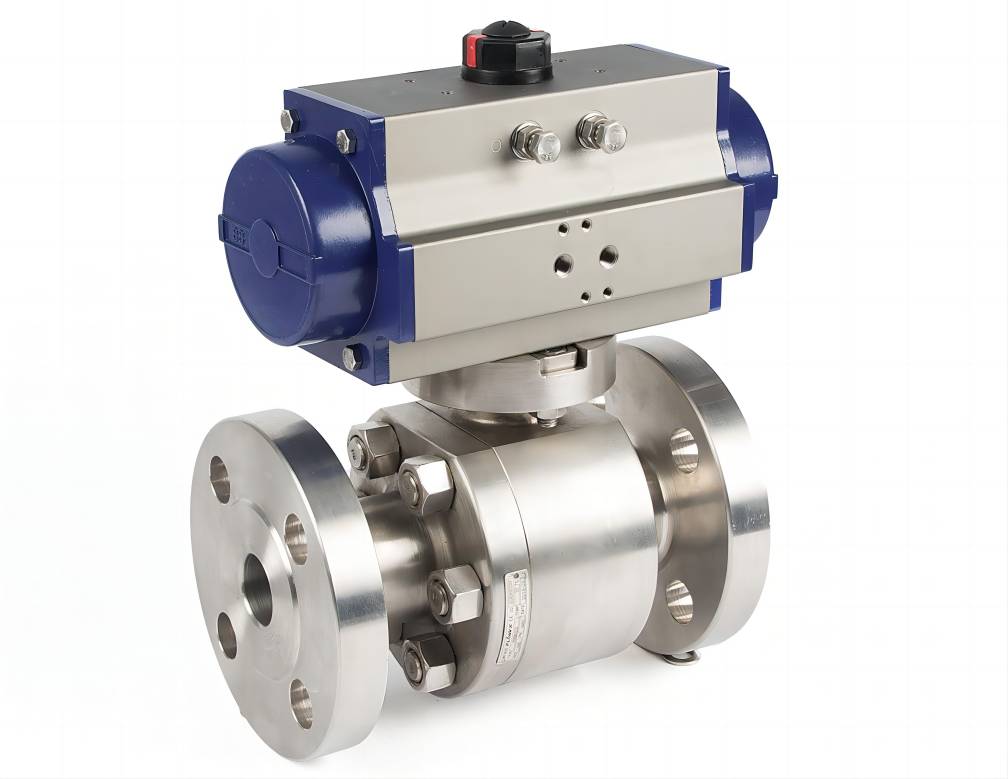

Valves and Instrumentations

Valve and instrumentation are necessary for the chemical injection skid to measure and track system activity. For instance, they will keep an eye on the liquid level inside the tank, allow the flow rate to be calibrated, and monitor and modify the system pressure. Additionally, it could activate alarms and other safety features intended to assure functionality and safety. Depending on the precise function of the chemical injection system and the client’s own unique requirements and wants, several gauges and valves may be used.

Electrical

The electrical system of a chemical injection system provides a means of starting or stopping the skid. Either locally or remotely is possible. For convenience and functionality, the various controls and functions typically go via a control panel.

Skid Structure

A skid structure will be a crucial component portion of all skid-mounted chemical injection systems. The skid structure provides the system with the necessary support and is designed to accommodate all of the system’s components while also protecting it. Usually, it will be made of continuously welded structural steel. It frequently includes a drip pan designed to catch spilled chemicals.

What does a chemical injection skid do?

Chemical injection skids are typically used to clean up any oil spills and other contaminated water in rivers and oceans. Chemical injection skids are used by a variety of sectors, not simply the oil and gas ones.

Chemical injection skids are also frequently used in the agriculture industry. To inject pesticides into waters, they commonly employ chemical injection skids. The mixture of insecticide and water is typically used to eradicate any pests in plantations.

Common chemical injection skid pumps on the market

Gear pumps

Centrifugal pumps

Positive displacement pumps

Diaphragm pumps

Metering type pumps

You can also find pumps for extremely caustic chemicals. People will usually use centrifugal pumps and gear pumps, as they are more popular. Both the pumps are made to be able to handle chemicals and are usually made from chemical-resistant materials.

Commonly used by oil & gas industries

Oil and gas industries are still the biggest users in using chemical injection skid pumps and for fair reasons too. Those oil and gas industry companies will usually increase their production with the help of chemical injection skid pumps.

The chemical injection assimilates software and hardware equipment. The same hardware equipment helps to impede any dangerous deposits and corrosion. It will also help to improve the quality of oil and gas before transporting it to their destinations.

The equipment that the O&G companies need may vary depending on its application, environment, and usage. It can be installed above ground, or even below ground. In some cases, it may be installed in deep water or other harsh environments.

A chemical injection skid system can offer additional advantages if used properly. They may help reduce internal corrosion in manufacturing tubes. Carbon dioxide and hydrogen sulfide are two potential culprits.

Additionally, it can get rid of accumulated minerals, excess salt, and wax deposits. All those accumulations may reduce product effectiveness.

After all of that, it can help to extend the duration between intrusive beneficial procedures if you combine all of these advantages. Chemical injection skid systems are a particularly reliable offshore investment because of all of the aforementioned advantages (and more).

Conclusion

A number of chemical injection skids are beneficial if you work in the oil and gas sector. Have at it even if you don’t work in the oil and gas sector but still need some.

If you require your organization to violently combine two different types of components, there is no harm in purchasing some. After all, the goal is to boost output while maximizing business profitability.