Chemical Injection Package – Precise Injection Empowers Efficient Extraction

Throughout the entire process of oil and gas field exploration and development, various chemical media such as foaming agent, defoamer, corrosion inhibitor, methanol, and ethylene glycol serve as the “industrial lifeblood” that ensures continuous, efficient, and safe production advancement. Different media fulfill distinct core missions, while precise, stable, and secure injection equipment acts as the key carrier to unleashing the effectiveness of these chemical media. Chongqing Weiyun (Wingoil) Technology Development Co., Ltd., with over a decade of experience in the oil and gas field industry, leverages top-tier technological collaborations and independent innovation capabilities to develop a series of chemical injection equipment that perfectly adapts to the injection needs of diverse media, delivering integrated solutions for on-site oil and gas field production.

Adaptable to Diverse Media, Precisely Tailored to Process Requirements

The injection scenarios for chemical media in oil and gas field sites are complex and variable, placing extremely high demands on equipment for pressure control, flow rate accuracy, and media compatibility. Wingoil’s series of purpose-built equipment comprehensively addresses the injection requirements of mainstream chemical media, ensuring that each media can deliver precise process value.

Anti-freezing, Anti-blockage, and Corrosion Prevention: The Core Assurance of High-pressure Precision Injection

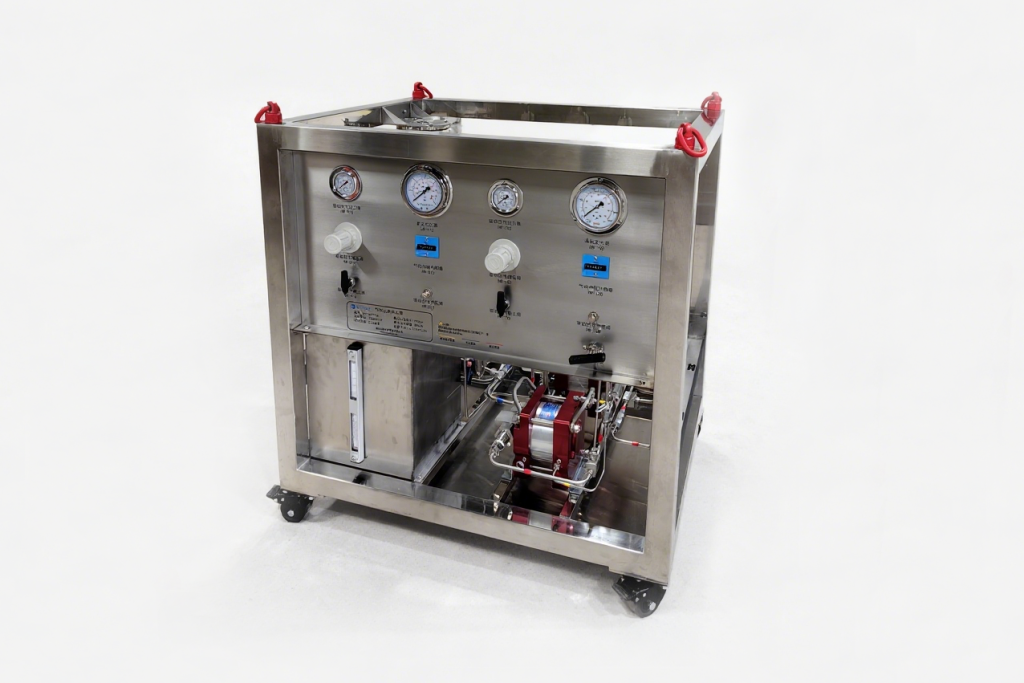

In high-altitude and cold regions or high-sulfur oil and gas fields, methanol and ethylene glycol, as core antifreeze and dehydration media, need to be injected stably under high pressure to prevent pipeline freezing and blockage. Corrosion inhibitor, on the other hand, must be calculated precisely and injected to form a uniform protective film against formation fluid corrosion. Wingoil’s WY-210CH-J2 Chemical Injection Package, with its ultra-high working pressure of 210MPa and precise flow rate control of 3.38L/min, easily handles the high-pressure injection demands of high-viscosity media such as methanol and ethylene glycol. It is equipped with four (4) air-driven chemical pumps to achieve fine-tuned flow rate adjustment, avoiding media waste and formation damage.

For media such as corrosion inhibitor that are susceptible to temperature changes, the equipment can be paired with the WY-1000L chemical storage skid, which integrates heating, insulation, and stirring functions to ensure that the media remains in a stable physical state and prevents uneven injection caused by sedimentation and stratification. The whole system employs a closed-loop design with an explosion-proof air compressor skid that provides a secure power source, making it completely adaptable to the harsh operating conditions of explosion-proof, high-temperature, and high-pressure environments in oil and gas fields.

Bubble Regulation: Intelligent Assistance for Efficient Development

The injection of foaming agent and defoamer directly affects oil and gas extraction efficiency—foaming agent can optimize gas-driven effects and enhance oil recovery, while defoamer can resolve the issues of foam accumulation within separation equipment. Leveraging its technological expertise in high-pressure equipment, Wingoil employs a modular design for injection system with an intelligent control system to achieve intermittent or continuous injection switching of foaming agent and defoamer.

The equipment features dual local and remote control capabilities, supporting both on-site operation and remote central control dispatch. Operators can dynamically adjust injection parameters based on real-time data such as wellhead pressure and fluid production to ensure foam concentration within the optimal range. Its independently developed “Protective Chemical Storage Skid” employs a special protective structure to prevent premature foaming caused by excessive contact between the foaming agent and air, thus ensuring injection stability.

Customized Services Plus End-to-end Guarantee, Empowering Efficient Development of Oil and Gas Field

Geological conditions and process requirements vary significantly across oil and gas field, making it difficult for standardized equipment to fully adapt to all scenarios. Wingoil adheres to the concept of “Precise Matching and Customized Empowerment”, providing personalized ultra-high pressure testing and injection system solutions based on users’ on-site operating conditions, medium characteristics, and production capacity requirements. From proposal, R&D and manufacturing to on-site installation, commissioning, and technical training, we offer full-process service support.

Leveraging its independent import and export rights, Wingoil collaborates extensively with renowned oil equipment manufacturers in the United States, the UK, Russia, and other countries. While keeping pace with cutting-edge international technologies, we have also built a comprehensive global supply chain and after-sales service network. A dedicated after-sales team provides 24/7 response, regularly conducting equipment inspections and maintenance guidance to ensure the injection system is always in optimal operating condition, safeguarding oil and gas field production.

From antifreeze and dehydration to corrosion control and foam regulation, Chongqing Weiyun (Wingoil) Technology Development Co., Ltd. delivers precise, safe, and intelligent chemical injection equipment to maximize the effectiveness of each chemical medium, providing core support for cost reduction, efficiency improvement, and safe development in oil and gas fields.

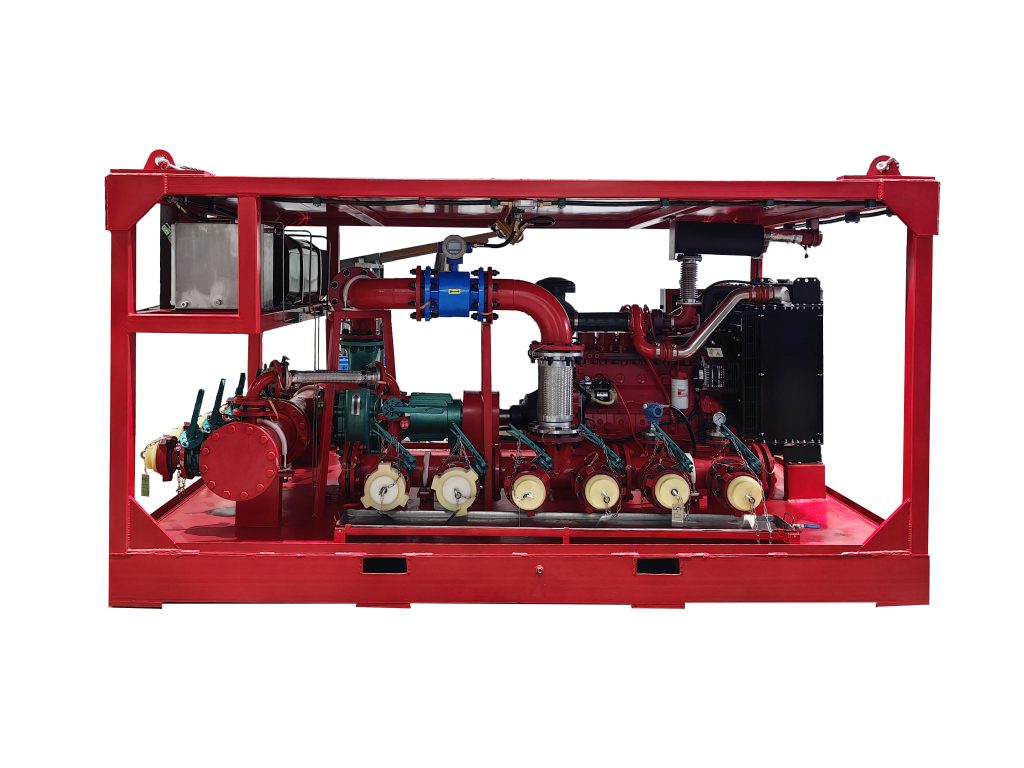

① Acid Injection Package

| Lift | Flow rate | Number of interfaces | Driving type |

| 50 meters | 0.2 to 9.1m³/min | Customizable | Electric, diesel |

- The inner linings of pipelines and pumps are made of corrosion-resistant materials.

- The pump shaft end is actively cooled to ensure service life.

- The diesel engine speed is adjustable.

- With high-quality clutch.