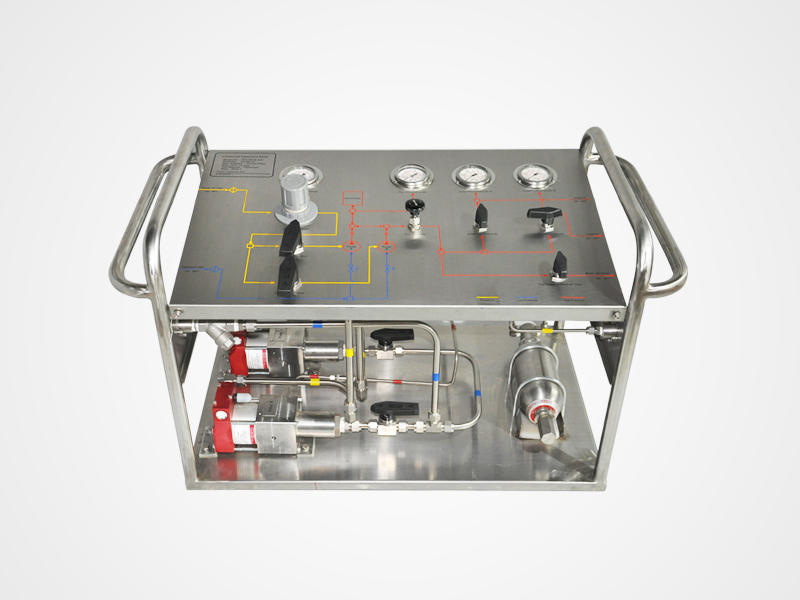

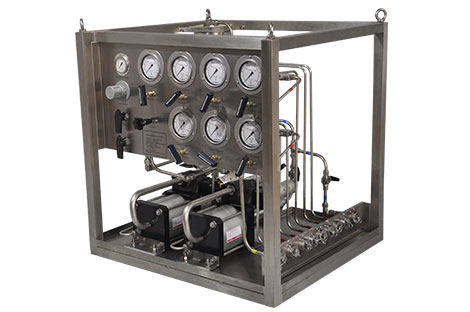

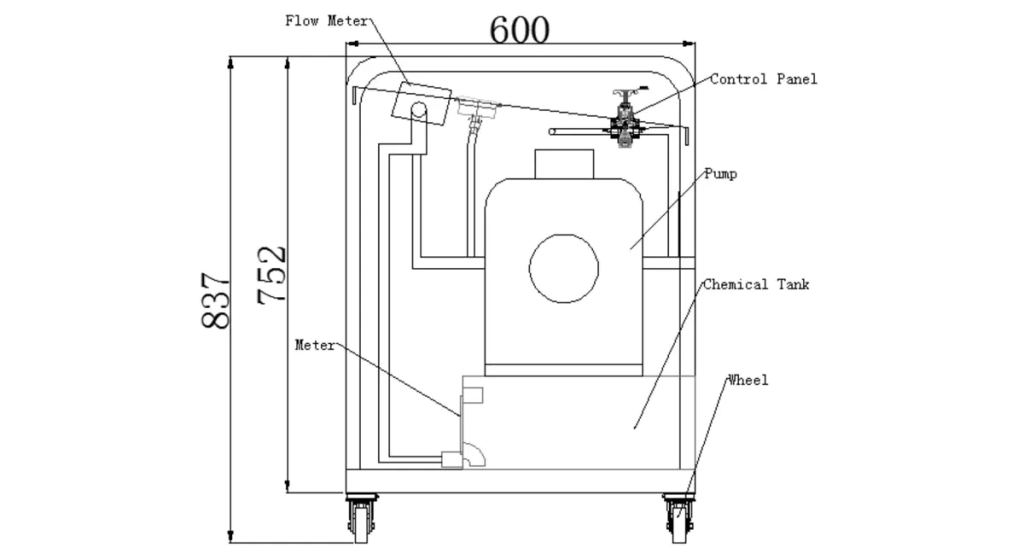

Chemical Injection System With Flow Meter

- Model: WY-250CH-J1

- The flow meter plays a vital role in the system, providing real-time measurement of the chemical flow rate, allowing for precise control and monitoring of the injection process. This enables operators to make informed decisions, adjust injection rates as needed, and maintain process stability.

Share to

Overview

Low-pulse chemical injection pump for injection of various chemical reagents. The air-driven hydraulic pump is used as the injection power source, and the injection pressure and the injection flow rate can be adjusted infinitely.

The equipment is equipped with an explosion-proof electronic flowmeter according to the flow rate, which can record and display the amount of chemical reagent injection for a certain period of time, and is especially suitable for occasions where the injection amount is strict.

Feature

- Low cost servicing.

- No heat, flame or risk of spark.

- Designed for ease of maintenance.

- Well proven and trouble-free operation.

- Compact, robust, self-contained structure.

- Dual scale shockproof pressure gauge display.

- Infinitely variable output pressure and flow rate.

- Holds static pressure without generating heat or consuming power.

- Low-pressure compressed air as the booster power source, safe and environmentally friendly.

- Pressure self-locking function, under the condition of setting the driving air pressure, the output pressure is constant.

- The flowmeter uses a lithium battery, which can display real-time and cumulative flow rate, and is designed to be explosion-proof and safe to use.

Model: WY-250CH-J1

Model: WY-250CH-J1

with Flow Meter

| Power source | Compressed air |

| Max. output pressure | 250 bar / 3600 psi |

| Max. flow rate | 32L/min |

| Air max. pressure | 10 bar / 145 psi |

| Power supply of flow meter | DC24V or lithium battery |

| Flow rate range of flow meter | 0.5 to 4 square/ hour |

| Diameter of flow meter | DN10 |

| Pressure of flow meter | 10 bar / 145 psi |

Connection

| Compressed air inlet | NPT1/2F hose |

| High pressure outlet | G1/4M |

| Safety valve outlet | 8mm tube |

| Sewage outlet | NPT1/2F |

| Water injection port | NPT1/2F |

| Relief valve | NPT1/2F |

Structure

| Panel | Stainless steel |

| Gas cylinder | Carbon steel |

| Pressure gauge | Stainless steel |

| Valve | Stainless steel |

| Tube | Stainless steel |

| Connections | Stainless steel |

| Hydraulic Cylinder | Anodized aluminium |

| Piston | Stainless steel |

| Booster pump head | Stainless steel |

Hydraulic Pressure Static Conditions (@7bar)

| Air pressure (bar) | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Hydraulic pressure (bar) | 0 | 40 | 80 | 120 | 160 | 200 | 240 | 280 |

| Output flow rate (L/min) | 35 | 24.6 | 28.4 | 15.2 | 13.7 | 12.6 | 11.4 | 10.6 |

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————