Gas Booster -Artifact of the Air Pressure System

Introduction

In the factory air compression system, since the manufacturing department often involves the addition of new equipment, or the compressed air pressure requirements of the equipment purchased by the process department are inconsistent, what should I do? Generally, when choosing an air compressor for a new plant, it will follow the principle of the highest pressure demand submitted by the process department (the principle of high or low pressure). If the pressure is low, a pressure-reducing valve can be added to meet the CDA pressure requirements of all process departments. However, the air compressor system has already been built. If the equipment demand is higher than the existing system, it will be a troublesome thing. Adding new air compressor pipelines will not only increase the cost but also the operation and management of the factory is also troublesome thing. The magic tool of a pressure – gas booster, can easily get rid of this trouble.

1. What is a gas booster?

The gas booster is also called a booster pump. The pump here is different from our water pump. It does not require any external energy (except compressed air). It can be connected directly to the gas pipe. It is as simple as installing a filter to increase it to 8 kg. Of course, the specific outlet pressure is also related to the selected supercharger model, and the boost ratio must be considered.

Whether to choose a supercharger or add another air compressor should be considered comprehensively. If the price of choosing a supercharger is more expensive than buying and installing an air compressor again, then there is no need to choose. However, the gas booster pump also has a disadvantage, that is The noise is relatively loud during operation, so the location of the supercharger still needs to be carefully considered, or noise reduction treatment should be adopted.

2. A gas booster in Wingoil

The following is the product description of a certain supercharger: it can be used as a reference.

2.1 Working principle of Wingoil gas booster

This is a device designed by our company to automatically double the air pressure of 0.2-0.8MPa. The main principle is to compress high-pressure air by using the principle of the difference in the action section. Due to the use of pneumatic power, and the use of special pneumatic reversing valves, it can automatically reverse and compress, without any other power or signal device, and it can be used normally only by ordinary compressed air, which is safe and convenient.

2.2 What is the advantage of a gas booster in Wingoil?

1. Easy to use: just enter the compressed air at the inlet, and the pressure at the outlet can be double or several times that of the inlet; automatic pressure replenishment keeps the pressure constant.

2. Safe operation: no arc and spark; safe to use in flammable and explosive gas or liquid places. 3. No need for special maintenance, convenient maintenance.

4. Energy saving and low cost of use: Air boosters are usually used in places where an individual or some devices in the gas circuit require high-pressure gas. Compared with building high-pressure gas stations, they are more environmentally friendly and energy-saving.

2.3 What kind of conditions can use Wingoil gas booster ??

1. Pressure test of valves, pipe fittings, pressure vessels, and gas source modification of processing centers;

2. It can meet the high-pressure demand of individual equipment in the factory, depending on the gas consumption.

3. When the pressure of the main air circuit of the factory drops and the minimum pressure of the pneumatic device cannot be guaranteed, the booster cylinder is used to supplement the pressure to maintain the normal operation of the device.

4. The space is narrow, and a large-diameter cylinder cannot be equipped, but the output force must be guaranteed;

5. Air-controlled remote operation must be pressurized to compensate for the pressure loss caused by the long air path.

6. It is necessary to increase the hydraulic pressure of the gas-hydraulic linkage cylinder.

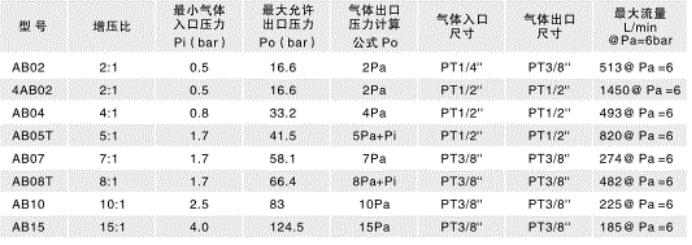

Technical Parameters of Gas Booster