Guide To Installation And Use Of Gas Booster Pump

The gas booster pump is a kind of equipment commonly used in the industry. It has a unique structural design, which can effectively reduce the temperature rise during the gas pressurization process. Therefore, it is particularly important to master its use method and precautions when using it.

What is a gas booster pump?

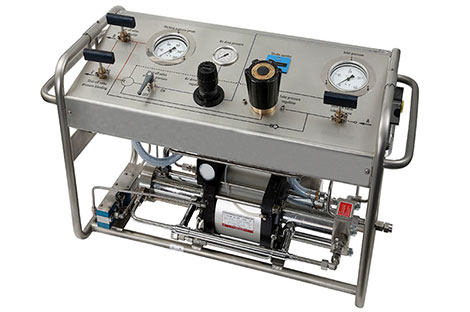

A gas booster pump, as the name suggests, is a device used to boost gas pressure. Its principle is to use the low-pressure gas to push the large piston to drive the small piston of the high-pressure booster cylinder. By calculating the area ratio of the large and small pistons, the booster ratio of the gas booster pump is obtained. If the area ratio of the large and small pistons is 10:1, the pressurized gas will have a 10-fold relationship with the driving gas. Because the boosting cylinder and the driving cylinder are separated, the purity of the pressurized gas will not be affected by other The effect results in a decrease in purity.

How to install a gas booster pump?

When installing the gas booster pump, it is necessary to avoid sundries from entering the inlet and outlet and keep the inlet and outlet clean. The driving gas should choose a clean gas source, which can ensure its continuous and stable operation of the driving gas. It is recommended to apply an appropriate amount of lubricating oil during its installation. Generally, lubrication is no longer required. If dry compressed gas is used for long-term driving, it is also necessary to add an appropriate amount of lubricating oil to its oil cup for lubrication.

The connection pipeline should select a suitable output connection pipeline according to its output pressure and can withstand its maximum output pressure inlet. The greater the inlet pressure, the greater the flow rate. Therefore, during the setting process, press The design of the pump should be set according to the environment or some work requirements.

Preparation before using the gas booster pump:

1. Check whether the connection of each pipeline is reliable.

2. Check the accuracy of each pressure indicator in each shift. If it is found that the error is large or the pointer does not move, it should be replaced in time.

Using methods and precautions of the gas booster pump

1. The user should prepare the pressurized gas and pipeline, the driving gas and pipeline, and the high-pressure gas outlet pipeline, fix the booster pump according to the instructions of the booster pump when it is delivered, and connect the pipeline according to the size of each inlet and outlet joint of the booster pump. Check whether the pressure is enough, whether there is leakage of the joint, etc., after the check is intact, you can carry out the pressurization test.

2. Gas source: the pressure range of the driving gas source of the gas booster pump is generally 1.8-8 bar. It is not recommended that the driving gas source exceed 10 bar. If the driving gas source is too high, it will cause damage to the pump body to a large extent, and even harm to the operator.

3. Gas booster pump selection: customers should choose the corresponding booster ratio according to the pressure of their own needs. According to the pressure needs of customers, we should focus on the air source pressure, intake pressure, output pressure demand, and flow rate, so that technicians can help you more accurately choose.

4. On the site use environment: the site use environment must be clean, can not have too large dust particles, driving air source and pressurized medium moisture content is not too much, otherwise it will greatly reduce the service life of the pump.

5. Requirements for pipelines: the sealing tightness of the high-pressure output pipeline must be tested when the customer uses it on-site, and the pipes, valves, and pressure gauges must be greater than the rated pressure output of the gas booster pump to maximize the safety of personnel operation.

6. Requirements for pressure vessels: all parts of pressure parts, especially the pressure vessels, must have the pressure safety vessel inspection report produced by the pressure safety vessel manufacturer.

About WINGOIL

WINGOIL is a professional manufacturer of gas booster equipment. With years of experience in equipment development and manufacturing, as well as experience in technical solutions, WINGOIL can provide customers with one-to-one customized products and services according to their actual needs.