How Oil Transfer Multiphase Pump Helps In Oil Transfer?

In the oil and gas industry, traditional pumps often face low efficiency and high maintenance costs when transporting unseparated mixtures of oil, water, and gas. The oil transfer multiphase pump is a highly efficient and reliable pumping solution that can safely convey mixed fluids to processing facilities without the need for complex separation, thereby significantly improving production efficiency.

Part 1. What is an Oil Transfer Multiphase Pump?

An oil transfer multiphase pump is an industrial pump capable of transporting liquid and gas oil-water mixtures. It differs from single-phase pumps in that it does not need pre-separation of the quantities of oil, water, and gas and, as such, can settle the fluid transport from the production site or wellhead effectively and reliably.

Part 2. Key Features of a Multiphase Pump

Multiphase pumps are designed for the co-transportation of oil, water, and gas in a single flow, offering a new way to overcome shortcomings of traditional pumping systems. They offer efficiency, reliability, and flexibility, making them essential to complex oil and gas operations.

The following are the main features that define their performance and advantages:

High-Efficiency Transportation

Multiphase pumps can transport mixed-phase fluids straight without previous separation or the need for multi-stage pumping. This minimizes the energy losses typically encountered with conventional separation processes and multi-stage pump arrangements with the added benefit of very much enhanced overall transport efficiency.

Energy-Saving and Environmentally Friendly

Energy-efficient and operating cost-saving pump designs minimize carbon footprint and reduce costs for oil and gas operators, where less power consumption helps easily meet the environmental and sustainability standards of the day.

Reliable Structure

Multiphase pumps are generally constructed using corrosion- and wear-resistant materials that are designed to withstand stable and long-term operations even under harsh offshore or harsh environment conditions. Such reliability minimizes downtime and maintenance.

Operability in Complex Conditions

They can handle high-viscosity fluids, high gas content, sand-carrying fluids, and other solids, and are also immune to cavitation or plugging. They are constructed robustly to withstand the extreme oilfield conditions in which they are being required to function and are an excellent all-around option for a wide range of fluid transport applications.

Part 3. Applications of Multiphase Pump in the Oil and Gas Industry

In offshore oil fields oil transfer multiphase pumps can transport crude oil that hasn’t been separated from the wellhead to platform processing facilities. Reliably and maintaining stable flow rates improves transport efficiency while simultaneously reducing the energy expended by the pipeline. The use of hydraulic multiphase transfer pump systems ensures safe and reliable management of complex mixed-phase fluids.

The application of multiphase pumps technology is not limited to the above mentioned examples:

Pipeline Transportation: These pumps can deliver to refineries or to storage terminals mixed-phase fluids which do not need to be separated, thus avoiding the need for intermediate stages of separating fluids and extra multi-pumping stations.

Enhanced Oil Recovery (EOR): These pumps are used in water and gas injection to improve the recovery from reservoirs without changing the flow regime.

Wellhead and Subsea: These pumps can be used in offshore and submerged regions where mobility is an issue.

The use of multiphase pumps technology helps Oil and Gas operators minimize the design and system equipment and operational expenses of the pipeline system while meeting productivity of the system and reliability.

Part 4. Advantages of Multiphase Pumps over Traditional Pumping Systems

Multiphase pumps offer a modern and efficient alternative to traditional pumping systems, addressing the challenges of transporting complex oil, water, and gas mixtures in the oil and gas industry. Here’s why they are increasingly preferred:

Direct Transport without Separation

In contrast with monopolizing systems that separate and require oil, water, and gas, with complex procedures, extensive machinery investment, and time-consuming operation, multiphase pumps can accommodate mixed-phase liquids directly.

This simplification removes complexities at various stages of production, trims down machinery and lifting-components for transporting liquids from wells to processing plants, and facilitates faster liquid transport.

Space and Capital Savings

The consolidated design of multiphase pumps within one assembly eliminates the need for multiple pumping stages and separate separation units. This optimization drives down pipeline and equipment footprint.

This is highly advantageous for offshore platforms or any other facilities with severe spatial constraints. Reduced infrastructure requirements lead to huge savings on capital expenditures.

Improved Reliability and Safety

The external casing of a multiphase pump is tailored for extreme situational conditions. The corrosion, suffix-high acute broad range, and viscosity-impervious nature of the pump is rated for extreme conditions.

The offshore platform, and extreme situational subsea and climatic environments, benefit from uninterrupted, safe pump operations. The robust construction of the multiphase pump, and compact structure reduces chances of mechanical failures.

Enhanced Operational Efficiency

Multiphase pumps integrate pumping and separation-free transport which leads to reduction in maintenance, down time as well as boosts overall production efficiency. This, in turn, helps operators to minimize total cost of ownership while enjoying uninterrupted flows needed for downstream processing and pipeline transport.

Part 4. Maintenance and Operating Tips of Multiphase Pump

To ensure long-term stable operation of a multiphase pump, the following guidelines are recommended:

Regular Component Inspection: Check impellers, seals, and pump casing for wear, corrosion, or damage. Early detection prevents unplanned downtime.

Monitor Operating Parameters: Keep inlet pressure, outlet flow, and gas content within design specifications to avoid cavitation and flow instability.

Avoid Exceeding Design Limits: Maintain fluid viscosity, gas content, and solids concentration within the pump’s rated range to prevent blockages and excessive wear.

Routine Lubrication and Replacement: Lubricate bearings and moving parts regularly, and replace seals, gaskets, and wear-prone components on schedule to prolong pump lifespan.

Operational Best Practices

- Gradually start the pump to avoid sudden load changes.

- Follow manufacturer guidelines for startup, shutdown, and emergency procedures.

- Maintain operational logs to track performance trends and anticipate maintenance needs.

Following these recommendations maximizes efficiency, reliability, and longevity, ensuring safe and continuous transport of complex fluids.

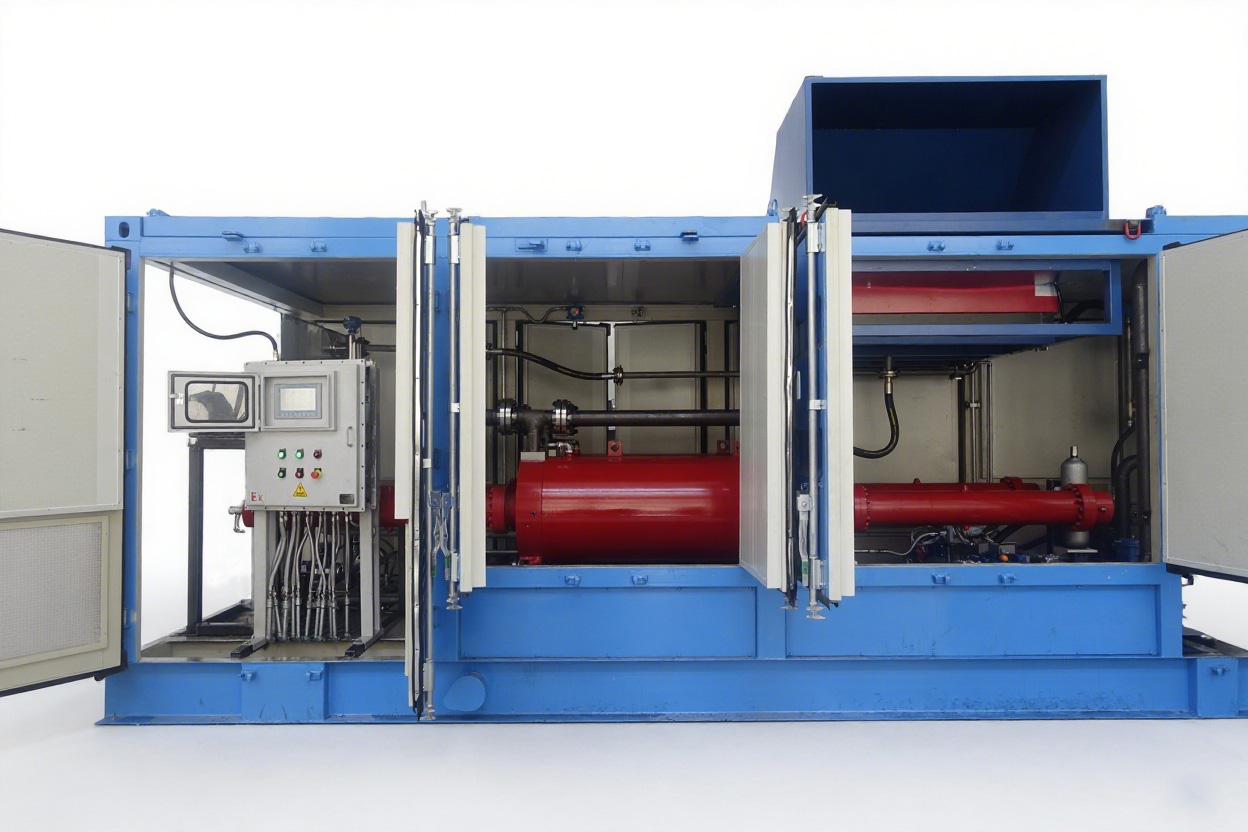

Part 6. Hydraulic Multiphase Transfer Pump System by Wingoil: Efficient Fluid Transport for Oil & Gas

Managing complex fluid flow in oil and gas production, especially with high gas and liquid content, requires reliable solutions. If you are looking reliable multiphase pump, Wingoil‘s Hydraulic Multiphase Transfer Pump System efficiently transports oil, water, gas, and solids, making it ideal for gas wells, oil-gas mixed wells, and challenging production conditions.

Key Advantages of Wingoil Hydraulic Multiphase Transfer Pump System

Direct Multiphase Transport

Eliminates the need for three-phase separators, reducing pressure losses and improving flow rates and gas-liquid transport capacity.

Boost Production and Extend Well Life

Lowers wellhead pressure and accelerates formation water removal, maintaining stable gas-liquid output and increasing recovery rates.

Energy Efficient

Consumes up to 50% less power compared to conventional pumps under similar production conditions, lowering operational costs.

Smart Control and Safety

PLC-based automated control, explosion-proof design, and remote monitoring ensure safe and reliable operation. Long-lasting seals and easy maintenance improve uptime.

Flexible Installation

- Skid-mounted for easy transport and setup

- Series configuration increases pressure; parallel configuration boosts flow

- Can use wellhead natural gas as gas-lift medium, reducing energy use

Applications

- Mid-to-late stage gas well production to relieve backpressure

- Single wells or multi-well clusters

- Gas wells and oil-gas mixed wells with high gas-liquid ratios

Support & Services

Wingoil provides full documentation and support, including quality certificates, inspection reports, explosion-proof certification, operation manuals, onsite operation plans, and emergency procedures, ensuring safe and reliable installation and operation.

Why Choose Wingoil?

Maximize oil and gas production, reduce energy consumption, and safely transport complex multiphase fluids with a single, high-performance system.

Final Words

The oil transfer multiphase pump is a modern, efficient, and reliable solution for fluid transport in the oil and gas industry. This not only reduces the cost of traditional separation equipment and multi-stage pumps, but also operates stably under complex fluid conditions. For applications such as offshore oil fields, pipeline transport, and enhanced oil recovery through water or gas injection, multiphase pumps have become an indispensable core technology.

Choosing a high-performance hydraulic multiphase transfer pump system from Wingoil can further improve transport efficiency and reduce operational costs. Our system delivers outstanding performance under challenging conditions, making it an ideal solution for oil and gas fluid transport.