How to Calculate Hydrostatic Test Pressure?

During manufacture, installation, or day-to-day use of pressure gear, a hydrostatic test acts as a safety checkpoint. By setting the right test pressure, operators confirm the unit meets plans and block leaks, blow-outs, or other dangers. So, how to calculate hydrostatic test pressure?

In this article, well explain the calculation, walk through the rules you must follow, note the factors at play, and point you toward fast, reliable test gear.

Part 1. What is Hydrostatic Test Pressure?

Hydrostatic test pressure is the extra force applied when clean water-or another non-compressible liquid-fills a pipe, tank, or vessel to uncover weak spots. The test pressure sits above normal operating levels so small flaws swell, leak, or burst under controlled conditions.

Key Purposes of Hydrostatic Testing:

Verify Pressure Resistance of Equipment

The main aim is simple: prove the unit can handle the pressure it will feel every day once installed. Meeting that goal shows the equipment matches blueprints and passes industry rules.

Detect Leaks and Weak Points

Fill the system, boost the pressure, and watch; hidden leaks, tiny cracks, or weak spots appear fast. Trouble usually hides at joints, flanges, welds, or fittings that everyday eyeballs never really examine.

Identify Manufacturing Defects Early

A hydro test flags rough machining, shaky welding, or trapped air bubbles long before the unit starts work. Catching these flaws now saves money, downtime, and safety fuss down the road.

Ensure Sealing Integrity of Connections

Flange gaskets, threaded nipples, and weld beads are all put under pressure to prove they hold tight. This final check is vital because a single loose seam can turn a routine job site into a risk zone.

Part 2. How to Calculate Hydrostatic Test Pressure?

The pressure used during this test is not arbitrary; it follows an industry rule that matches safety with practical gear limits.

Hydrostatic Test Pressure = Design Pressure × Test Factor (1.3 ~ 1.5)

Breakdown of Key Terms:

Design Pressure (DP):

Design Pressure, or DP, is the maximum pressure that the equipment is designed to withstand under normal circumstances. Engineers determine this figure early in the process, balancing production needs against a safety margin so that pipes do not burst on the shop floor.

Test Factor (TF)

The Test Factor, which can be abbreviated as TF, is merely a multiplier that is applied to produce pressure for a hydrostatic leak test. Depending on national codes or industry standards, TF varies from 1.25 to 1.5.

Example Calculation:

Imagine a pressure vessel designed to run at 10 megapascals (MPa), and the governing standard tells you to use a test factor of 1.5.

You simply multiply:

Hydrostatic Test Pressure = 10 MPa × 1.5 = 15 MPa.

That means the vessel sits in water-or another test fluid-pressurized to 15 MPa while technicians look for leaks and watch how the metal behaves.

Reference: Common Standards

| Standard | Test Factor | Description |

| ASME B31.3 | 1.5 | For new piping systems in process plants (chemical, refinery). |

| GB/T 9251 | 1.25–1.5 | Hydrostatic test for pressure vessels in China. |

| API 570 | 1.5 | Widely used in petroleum and petrochemical industries. |

Note: Always check the exact code that applies in your workshop or plant. Factors may change based on the material, operating temperature, and how risky the service is.

Using the right formula and following the proper code lets engineers test pressure equipment in a way that is safe, correct, and in line with both legal rules and day-to-day needs.

Part 3. Factors Affecting Hydrostatic Test Pressure Calculation

Even though the formula to set hydrostatic test pressure looks simple, several key factors can tip the final pressure setting one way or the other. Overlooking any of these may produce tests that are either off target or dangerous.

Material Strength

Every material has its own yield strength and stress limit. Carbon steel, stainless steel, and composites behave differently when pressed. The test pressure can’t go beyond what the material can handle at the test temperature, especially if the material is brittle or not very ductile.

Operating Temperature

High heat or cold can make a material softer or more brittle than it is at room temperature. Though tests are often run at ambient levels, the design pressure usually comes from the highest operating temperature, and that fact should shape the test multiplier.

Equipment Type

The equipment under test-chilled or hot, flowing or static-pipes, heat exchangers, pressure vessels-dictates which code book tells you what to do. For instance:

- Pipelines typically follow ASME B31.3 or GB 50251

- Pressure vessels usually come under ASME Section VIII or GB/T 9251

Every industry standard gives its own test method and the pressure boost it demands.

Test Medium

Water is the go-to fluid for hydrostatic checks because it does not compress and poses little danger. Still:

- If you switch to another liquid, ask if it rusts metal or adds too much weight.

- Never use compressed gas; it can hold enormous energy and explode if a seam fails.

Local Standards and Regulations

Rules differ from place to place and between factories. For instance:

- In the U.S. people lean on ASME or API.

- China sticks to GB/T codes.

- Europe often cites EN rules.

Make sure your job meets the standard that rules your site or industry.

Part 4. Common Mistakes and Key Precautions of Hydrostatic Test Pressure Calculation

Even seasoned techs can miss small-but-critical details. Watch for these slip-ups to keep every hydrostatic test safe and effective.

Common Mistakes:

Using Operating Pressure Instead of Design Pressure: Operating pressure is usually lower and does not cover peak loads. Always use the design pressure as the base for calculation.

Ignoring Specified Test Factors from Standards: Failing to apply the correct multiplier (e.g., using 1.2 instead of 1.5) can result in under-testing and non-compliance.

Exceeding Maximum Allowable Test Pressure: Putting too much pressure on a system can bend parts, cause permanent deformation, or even end with a spectacular blowout.

Best Practices

Always Use a Liquid Medium (Preferably Clean Water): Compressed gas can explode, so stick with water or a safe liquid. If you add antifreeze or another chemical, double-check that it wont eat away at the test materials.

Monitor Pressure Stability During the Test: Hold the pressure for the time rule book says, then watch for drops or leaks.

Document the Test Process and Results: Write down every detail-pressure, time, gear, and what you saw. Solid records back compliance and help during audits.

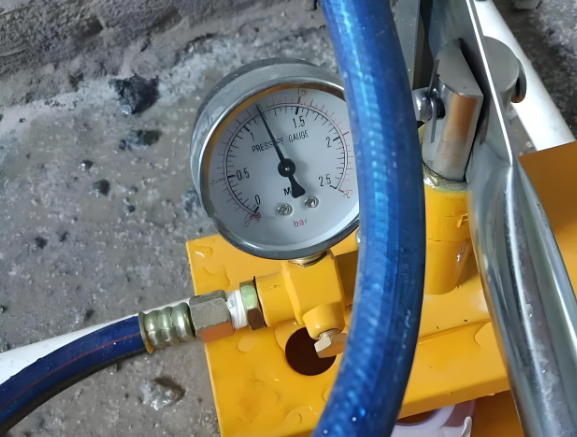

Part 5. Recommended Equipment: Wingoil Mobile Hydrostatic Test Workshop

Choosing the right gear matters as much as the math behind the test. For that reason, we suggest the Wingoil Mobile Pressure Test Workshop, a pro-grade kit that suits many field jobs.

Key Product Highlights

Integrated Testing Functions

This compact unit carries out hydrostatic, pneumatic, and leak tests all in one box. Its perfect for pipes, valves, vessels, and any other pressure-holding gear.

Field-Ready, Trailer-Mounted Design

The unit rides on a sturdy trailer so crews can hitch it to a pickup, cross rough roads, and park it right where the work is. That mobility suits tests on pipelines, tanks, or gear far from base camps or in fast-moving building yards.

Smart Control System

Inside, a touch-control screen tracks pressure live, collects readings on its own, and stores each run in read-along logs. Operators get clear numbers and a duty record every time, helping catch small drifts before they grow.

Multi-Medium Compatibility

Water, nitrogen, CO2, or oxygen-whatever the job needs, the system swaps seals and settings fast to match. That versatility cuts downtime and lets the same trailer serve several contracts without costly fixes.

Enhanced Safety Features

When the preset limit lands, built-in sensors trigger a gentle stop and vent loose pressure. The rig stays cool with no added current, removing the fire risk that comes with over-heat components.

User-Friendly Operation

Crew leaders steer tests from yards or trucks via remote buttons, watch live angles on fold-out cameras, and talk through clear intercoms. That keep everyone linked without crowding around tight gear.

Whether the task is piping, valves, or heavy pressure vessels, the Wingoil Mobile Pressure Test Workshop delivers steady output, razor-sharp control, and toughness earned through years on-site. Field pros lean on it when speed, range, and pinpoint accuracy have to show up at the same place.

Final Thoughts

Hydrostatic testing is more than just a routine step; its the insurance that keeps heavy machines running safely on the job site. When you nail the math, follow the right standards, and pick good equipment, you give every project a better shot at quality and safety.

Wingoil is your go-to company for all-in-one pressure-testing services. Reach out today and let their friendly team guide you with expert advice and a custom solution that fits your needs.