Overview

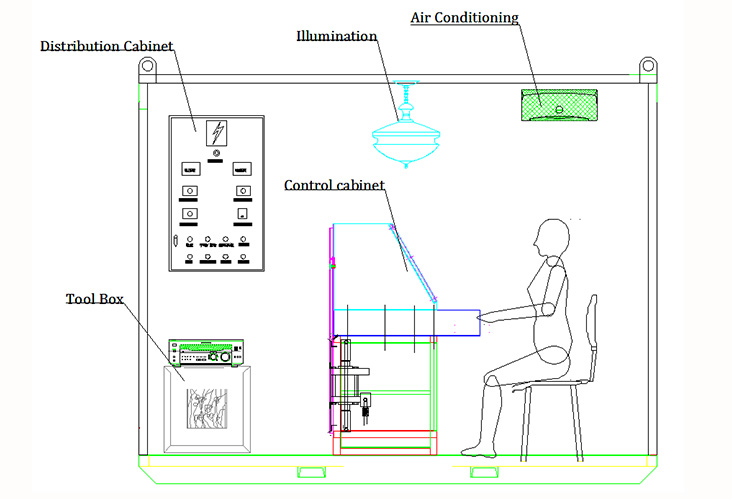

The mobile pressure test workshop is a set of pressure test equipment, data acquisition system, voice and video monitoring system in a small container, used to complete various types of pressure testing and injection. Due to the necessary lighting, heating and other ancillary facilities in the mobile pressure test room, it is especially suitable for field operations and the need to change the work site frequently.

Testing pump, nitrogen, carbon dioxide pressurization, oxygen, nitrogen production, nitrogen generator, mobile pressure test workshop, flow supercharger

Features

- Infinitely variable output pressure and flow

- Holds static pressure without generating heat or consuming power

- When the set pressure is reached, the equipment automatically stops and is safe to use

- Easy to transport and hoist;

- Remote control

- Real-time display of test data, data recording, and data check

- Multi-angle video surveillance

- With lighting, temperature control, and voice calls functions.

- Capable of pressurizing liquids and gases;

Clear Water Pressure Test

| Test medium | Clear water |

| Low-pressure pump max output pressure | 60 bar / 6 Mpa |

| High-pressure pump max output pressure | 1500 bar / 150 Mpa |

| Output interface | G1/4-60° |

| Hose length | 15 meters (blue) |

| Hose pressure | 1500 bar / 150 Mpa |

| Number of output interfaces | 1 with 2 |

Gas Pressure Test

| Test medium | Nitrogen, air |

| Max. output pressure | 750 bar / 75 Mpa |

| Output interface | G1/4-60° |

| Hose length | 10 meters (color change) |

| Hose pressure | 750 bar / 75 Mpa |

| Number of output interfaces | 1 with 1 |

| Nitrogen inlet hose length | 10 meters (black) |

| Nitrogen inlet thread | G1/2 |

Hydraulic Oil Pressure Test

| Max output pressure | 90 bar / 9 Mpa |

| Interface size | M14×1.5 |

| Hydraulic hose pressure | 250 bar / 25 Mpa |

| Number of hydraulic hoses | 4 every 15 meters (black) |

Pressure Test Center Control Room

| Dimension | 3000L*2000W*2700H (mm) |

| Weight | 1000 kg |

| Power supply | 220AC 50Hz |

Connection

| Air inlet | 1 inch |

| Clear water output | G1/4-60° |

| Gas output | G1/4-60° |

| Hydraulic oil output | G1/4-60° |

Construction

| Frame | Stainless Steel |

| Water tank | Stainless Steel |

| Pressure gauge | Stainless Steel |

| Valve | Stainless Steel |

| Tube | Stainless Steel |

| Connections | Stainless Steel |

| Hydraulic Cylinder | Anodized aluminum |

| Piston | Stainless Steel |

| Booster pump head | Stainless Steel |

| Workshop wall | Insulation Materials |

| Air Pressure (bar) | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

| Hydraulic Pressure (bar) | 0 | 250 | 500 | 750 | 1000 | 1250 | 1500 | 1750 |

| Output flow rate | 0.77 | 0.65 | 0.5 | 0.43 | 0.38 | 0.34 | 0.26 | 0.2 |

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————