How to Set Up Chemical Injection Pump? – Step by Step Guide

In the oil & gas, chemical, and water treatment industries, chemical injection pumps are widely used for the precise dosing of corrosion inhibitors, scale inhibitors, biocides, and acidic chemicals. However, many project failures are not caused by the equipment itself, but rather by improper system installation and configuration.

Today, we will take a system-level perspective to provide a detailed explanation of how to set up chemical injection pump, helping you understand how a complete chemical injection system should be correctly installed, commissioned, and put into operation.

Part 1. Understanding the “System Nature” of a Chemical Injection Pump

In practical engineering operations, a chemical injection pump is seldom run as an independent unit. It is, in fact, an important subsystem of a comprehensive chemical injection system, developed to provide precise, consistent, and safe delivery of chemicals under set process conditions.

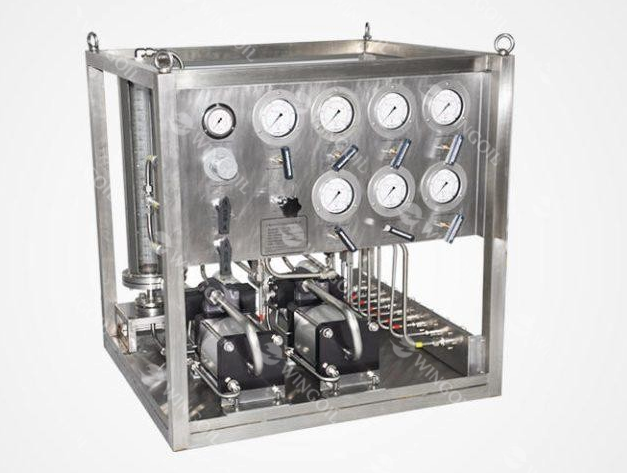

A typical chemical injection system will normally include the following components:

Metering pump (Plunger or Diaphragm type): Functions for providing a specific and measurable chemical flow rate against the system pressures.

Chemical storage tank: It was designed to store corrosion inhibitors, scale inhibitors, biocides, acid, or other chemicals used in treatment. It came with level indictors and vented devices.

Injection valve (Injection quill/check valve): This controls proper chemical distribution into the processing pipe and also prevents backflow and protects the pump.

Pressure gauges and safety relief valves: Used to monitor system pressure and protect equipment from overpressure conditions.

Piping and fittings: All components should be connected together and should be compatible with the chemical properties, pressure range, and operating conditions.

Control system (electric or pneumatic): Facilitates manual or automated adjustments in injection rates, which may be integrated with flow signals, PLCs, or DCS systems.

Due to this integration on a system level, it becomes apparent that establishing a chemical injection pump and handling it is no longer a matter of installing a chemical injection pump alone.

In other words, establishing a chemical injection package or injection skid is involved. A good configuration setup is important for the accuracy of the dose delivery, functionality, and stability of the system, while a poor setup system can result in misfiring of the injection or project failures.

Part 2. What to Do Before You Set Up a Chemical Injection Pump?

Proper site condition evaluation before chemical injection pump or system installation is critical. It directly impacts the selection of equipment, system configuration, and the reliability of its operation over time.

Key factors to verify include:

Operating pressure and temperature at the injection site

The pump, injection valve, tubing, and fittings shall be rated to withstand actual process pressure and temperature. Underrated components can result in leakage or seal failure, or pose a safety hazard.

Type of chemical and corrosiveness

Different wetted materials – for example, stainless steel, Hastelloy, PTFE – might be needed for different chemicals. Compatibility assessment allows the prevention of corrosion or swelling of materials, or the failure of a component at an early stage.

Availability of power supply or instrument air

Confirm whether electrical power (voltage, frequency, hazardous area classification) or pneumatic air supply is available, as this determines whether an electric or air-driven pump and control system should be used.

Installation space and layout suitability

Ensure there is sufficient space for maintenance access, chemical replenishment, and safe operation. This is especially important when installing skid-mounted equipment in confined or offshore locations.

When it comes to real projects, the use of a pre-assembled chemical injection package or an injection skid could help resolve some on-site uncertainty. Factory-assembled installations would entail some pre-testing, which would, not only improve the efficiency of the installation but would also shorten the commissioning time and avoid some possible mistakes that could occur during onsite installations.

A proper plan prior to installation will ensure that a chemical injection system can be installed without complications and function properly.

Part 3. How to Set Up Chemical Injection Pump?

Step 1. Positioning and Securing the Chemical Injection Pump and Skid

Once pre-installation checks are complete, the next step is to correctly position and secure the chemical injection pump and its skid. Proper placement and fixation are critical for stable operation, accurate dosing, and long-term equipment reliability.

1. Skid Location Selection

When selecting the installation location for the injection skid, consider the following principles:

Close to the injection point

Installing the skid near the injection point helps minimize piping length and pressure losses, improving dosing accuracy and reducing response delays.

Away from high-temperature or vibration sources

Excessive heat or continuous vibration from nearby equipment can negatively affect pump performance, seals, and instrumentation, leading to premature wear or unstable operation.

Easy access for operation and maintenance

Adequate clearance should be provided for routine inspection, calibration, chemical refilling, and component replacement. Good accessibility reduces downtime and improves safety.

2. Equipment Fixation and Stability

After positioning, the skid must be firmly secured to prevent movement during operation:

Ensure the skid is level

A level installation helps maintain proper pump alignment, ensures accurate stroke adjustment, and prevents uneven stress on piping connections.

Secure using anchor bolts or base supports

Anchor bolts or a rigid base frame should be used to fix the skid to the foundation, ensuring stability under operating pressure and pulsation.

Prevent displacement during operation

Fixation prevents any movement that results from pump oscillations, pressure surges, or external pressure. This helps protect both the pump and its piping connections.

In the case of acid injection packages, there are some extra concerns that one has to keep in mind. Such packages require the flooring, protection from spills, and barriers that are corrosion resistant so that the nearby structures and personnel are not harmed due to the chemicals involved.

Proper positioning and installation help build a strong foundation for the safe, efficient, and reliable performance of chemical injection systems.

Step 2. Piping and Valve System Connection

This is one of the most important steps in the chemical injection pump system setup because piping and vale configurations greatly affect system stability and accuracy.

Suction piping should be short and direct whenever possible

A short suction line with few turns ensures less pressure losses and prevents cavitation. A suction piping of larger diameter and absence of pockets will provide a constant supply of chemicals to the pumping units.

Discharge piping has to be designed for the maximum system pressure

The output line, fittings, and tubing must meet or exceed the highest operating and shutdown pressures of the injection system, respectively. Underrated discharge components are a common cause of leaks and system failure.

Check valves must be installed to prevent backflow

Properly selected and positioned check valves protect the pump from reverse flow, prevent process fluid from entering the chemical line, and maintain consistent injection performance.

Pulse dampeners are recommended for high-pressure systems

For plunger pumps or high-pressure applications, pulse dampeners help absorb pressure fluctuations, reduce vibration, and protect downstream piping, valves, and instruments.

In factory-prefabricated chemical injection skids, these critical components are typically engineered as an integrated system. Pipe routing, valve selection, and pressure ratings are optimized during design, and the entire skid is pressure-tested before delivery. This significantly reduces installation risk and ensures reliable performance once the system is commissioned on site.

Step 3. Control System and Drive Configuration

The control system and drive method are key factors that determine how accurately and reliably a chemical injection pump operates. Based on available site utilities and application requirements, chemical injection pumps are typically configured in one of the following ways:

1. Electric Chemical Injection Package

Electric-driven systems are commonly used in facilities with a stable and reliable power supply:

Suitable for sites with consistent electrical power: These systems can be easily integrated into existing plant power infrastructure.

Supports PLC, VFD, and remote control: Injection rates can be adjusted automatically based on flow signals, pressure feedback, or process demand, making them ideal for fully automated operations.

High metering accuracy and repeatability: Electric pumps provide precise stroke and speed control, ensuring consistent chemical dosing over long operating periods.

2. Pneumatic Chemical Injection Skid

Pneumatic systems are preferred in hazardous or remote environments:

Ideal for explosion-proof or no-power locations: Air-driven pumps eliminate electrical ignition risks and are well suited for ATEX or offshore applications.

Pump speed controlled by instrument air: Injection rates are regulated through air pressure or flow control, offering simple and reliable operation.

Commonly used in oilfields and offshore platforms: Because of their robustness and safety features, they are widely used for upstream oil and gas operations.

While setting up, there is a need to ensure that there is a connection between the type of control used and the requirements for the pumping unit. Other factors that may need to be considered include automation, classification, dosing accuracy, and operating environment for the chemical injection system to function properly.

Step 4. Pressure Testing, Calibration, and Commissioning

Once installed, the chemical injection system has to be thoroughly checked and commissioned before it can be put to actual operational use.

Hydrostatic or inert media pressure testing

The system testing is done using water or an inert fluid to check pressure integrity without using dangerous chemicals on the equipment. This checks the system to see that it can resist the design pressure safely.

Leak inspection

All joints, seals, and connections are carefully inspected under pressure to establish any potential points of leakage which may be a source of a chemical loss or danger.

Valve sealing verification

Check valves, isolation valves, and safety valves are tested to ensure proper sealing and correct flow direction, preventing backflow or pressure loss.

Pump flow rate calibration

The injection pump is calibrated under actual operating conditions to confirm that the delivered flow rate matches the design dosing requirements. This step is critical for chemical effectiveness and cost control.

Verification of dosing accuracy

The actual chemical injection rate is compared against process requirements to ensure consistent and accurate chemical treatment.

Safety function testing

Pressure relief devices are verified to open at the correct set pressure, emergency shutdown systems are tested to ensure the pump and system can be safely stopped in abnormal conditions

Only after all tests and verifications are successfully completed can the chemical injection pump and the entire injection system be officially commissioned and put into continuous operation. Proper commissioning significantly reduces the risk of operational failures and extends system service life.

Part 4. Common Installation Mistakes and Manufacturer Recommendations

In practical projects, many chemical injection system issues are not caused by pump quality, but by avoidable installation and configuration mistakes. The most common problems include:

Ignoring chemical compatibility

Selecting incorrect wetted materials can lead to seal swelling, corrosion, or rapid degradation, ultimately causing leakage and pump failure.

Incorrect piping selection with insufficient pressure rating

Using tubing or fittings that do not meet the maximum system pressure can result in deformation, leaks, or even safety incidents during operation.

Lack of safety and pulse control components

Failing to install safety relief valves or pulse dampeners increases the risk of overpressure, vibration, and unstable flow, especially in high-pressure or plunger pump systems.

On-site temporary assembly

Field-assembled systems are known to have some irregularities regarding layout, work, and testing, resulting in less stable systems and increased maintenance costs.

A manufacturer can best address these concerns by choosing an integrated chemical injection package or skid from a factory. The systems are manufacturer-prepared with the right material of construction, pressure rating, and safety features before being shipped out to the end-use location.

Manufacturers like Wingoil, due to their knowledge in chemical injection pumps and packaged injection skids, offer end users fully functional, pre-assembled packages that ultimately assist in reducing mistakes encountered in installation, lowering startup time, and obtaining efficient dosing in relation to chemicals.

Part 5. Why More Projects Are Choosing Integrated Chemical Injection Packages

Compared to field-assembly systems, factory-integrated chemical injection packages or skids have various benefits, making them increasingly popular in the oil & gas, chemical process, and water treatment industries because of the following reasons:

Lower installation & commissioning time

Pre-integrated and pre-tested skid systems are ready for connection when they are delivered on site, which greatly limits the need for on-site workers and could reduce the risk of error, thus

System layout and structures design optimization

Factory-integrated systems enable efficient layout of pumps, valves, piping, and control instruments to provide stable flow, accessibility, and safety. This layout eliminates some common mistakes associated with field assembly layouts.

Pressure testing completed before shipment

Each skid is pressure-tested at the factory to verify integrity and identify potential issues early, providing higher confidence during commissioning and operation.

Improved long-term operational reliability

Factory integration ensures proper material selection, valve placement, and pulse damping, which significantly reduces maintenance needs and minimizes downtime over the system’s lifecycle.

Simplified project acceptance and compliance

The pre-assembled system with available testing data helps in smoothly passing the regulatory inspections and acceptance tests by the clients.

Because of these factors, chemical injection skid systems have become mainstream in the oil & gas, petrochemical, and water treatment industries at an incredible pace. The reliability, efficiency, and safety that these systems offer have made them preferable for modern chemical injection applications.

Conclusion: Proper Setup Determines Long-Term System Performance

“How to set up a chemical injection pump” is a lot more than just placing a pump because it can be a system-level engineering process with designs and considerations based upon safety and control.

Within applications that require reliable function and uptime, having a system integration background with chemical injection pumps may be a much more significant advantage when selecting a manufacturer than just looking at individual products.

Those searching for a total solution to buy can benefit from Wingoil’s chemical injection packages and skids, which are fully assembled and tested at the factory to ensure a reliable system that is free from errors during installation and maintains accurate chemical dosage.