Pressure Testing Wellheads: The Vital Role of Pressure Test Skids in Oil and Gas Production

A wellhead pressure test skid is an essential downhole tool used in the oil and gas industry to test the integrity and performance of a wellhead system. It is a device designed to pressurize the wellhead and associated equipment to the maximum allowable working pressure (MAWP) to ensure that there are no leaks or other issues that could compromise the safety and effectiveness of the system. In this article, we will explain the working principle of the wellhead pressure test skid, the importance of the device, and how it works.

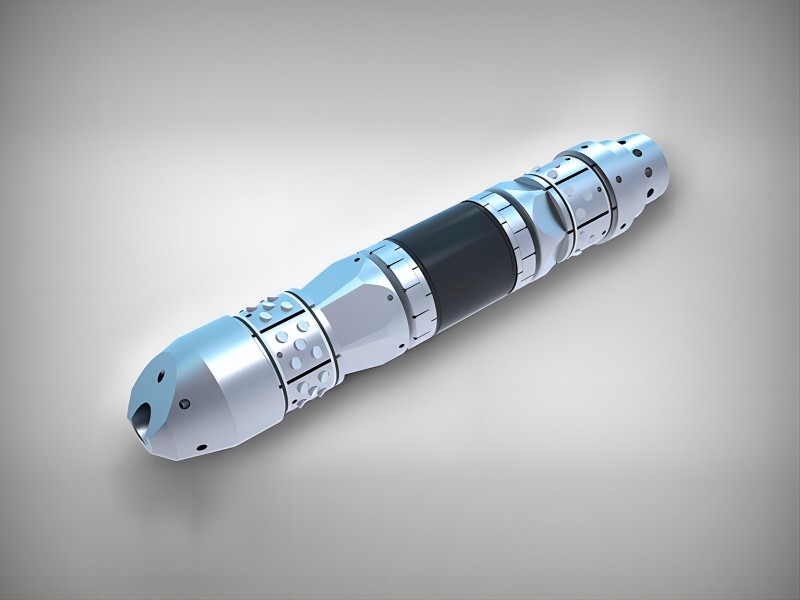

Wellhead Pressure Test Skid Components:

A wellhead pressure test skid typically consists of pumps, valves, gauges, fittings, hoses, and other equipment. The pumps are used to pressurize the wellhead, while the valves control the flow of fluid into and out of the wellhead. Gauges are used to monitor the pressure, while fittings and hoses are used to connect the skid to the wellhead.

Working Principle of Wellhead Pressure Test Skid:

Before the wellhead pressure test is conducted, certain procedures must be completed. The first step is to ensure that all equipment used for the test is in good working condition. Next, the area around the wellhead must be cleared of debris and other materials that could interfere with the test.

To conduct the wellhead pressure test, the wellhead pressure test skid is connected to the wellhead using hoses and fittings. The skid is then used to gradually pressurize the wellhead to the required level. During this process, pressure gauges and other instruments are used to monitor the pressure and identify any changes or anomalies.

If there are any leaks or other issues, they can be detected and addressed before the well is put into production. Once the test is complete, the pressure is gradually released, and the equipment is depressurized. The results of the test are then recorded and analyzed to ensure that the wellhead and associated equipment are in good working order and ready for production.

Importance of Wellhead Pressure Test Skid:

The wellhead pressure test skid is an important pressure testing equipment for ensuring the safety and reliability of oil and gas production equipment. By testing the integrity and performance of the wellhead system, operators can identify and address issues before they become a problem and avoid costly downtime and repairs.

The early detection of leaks and other issues is crucial for avoiding accidents and ensuring compliance with industry regulations. Regular wellhead pressure testing is an important part of routine maintenance for oil and gas production equipment and is necessary for ensuring that the equipment is safe and reliable.

Conclusion:

In conclusion, the wellhead pressure test skid is an essential tool for the oil and gas industry. The device is used to test the integrity and performance of a wellhead system by pressurizing it to the maximum allowable working pressure. By identifying and addressing issues early on, operators can avoid costly downtime and repairs while ensuring compliance with industry regulations.

Regular wellhead pressure testing is a necessary part of routine maintenance for oil and gas production equipment and is necessary for ensuring that the equipment is safe and reliable. The wellhead pressure test skid plays a crucial role in this process, and its importance cannot be overstated. By investing in this essential tool, oil and gas companies can ensure the safety and reliability of their equipment while avoiding costly downtime and repairs.