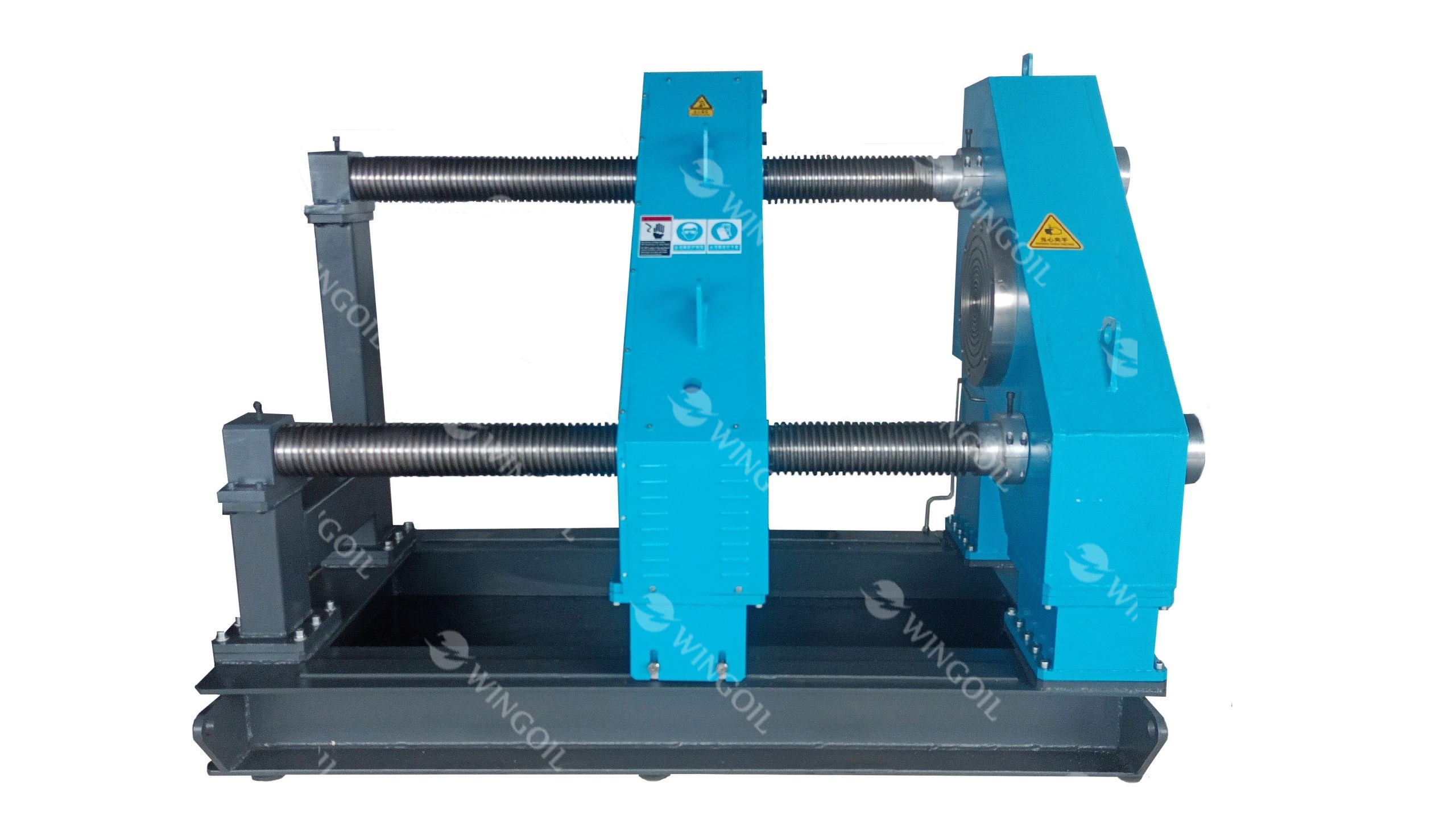

Horizontal Valve Test Bench

- Easy to operate and get started.

- It’s widely used in valve manufacturing, petroleum, petrochemical, nuclear power, chemical industry, etc.

- The valve test benches is mainly used to test the strength, sealing and leakage of various types of high, medium and low pressure valves.

Share to

Overview

The valve test bench is a customized equipment produced according to the user’s requirements for valve pressure testing.

FAQ

| ① Driving air source pressure is too low (Driving Air Source Pressure * Boost Ratio = High-Pressure Outlet Pressure) | a. Check whether the driving air pressure reaches the rated value. b. Listen for air leaks or abnormal noises in the air loop. c. Adjust the driving air pressure to the required value. |

| ② Filter—Pressure Regulator Component Failure | Check if the pressure regulator filter is blocked or if there is water accumulation. |

| ③ Abnormal clamping device operation | Check whether the front, rear and lifting pipelines of each clamping jaw are connected correctly. |

| ④ Insufficient hydraulic system pressure | Check whether the oil tank level meets the requirements. |

| ⑤ The throttle valve of the clamping jaw’s actuating cylinder is too tight. | Gradually loosen the throttle valve while conducting operational tests to verify performance until the hydraulic cylinder jaws resume smooth and stable operation. |

Feature

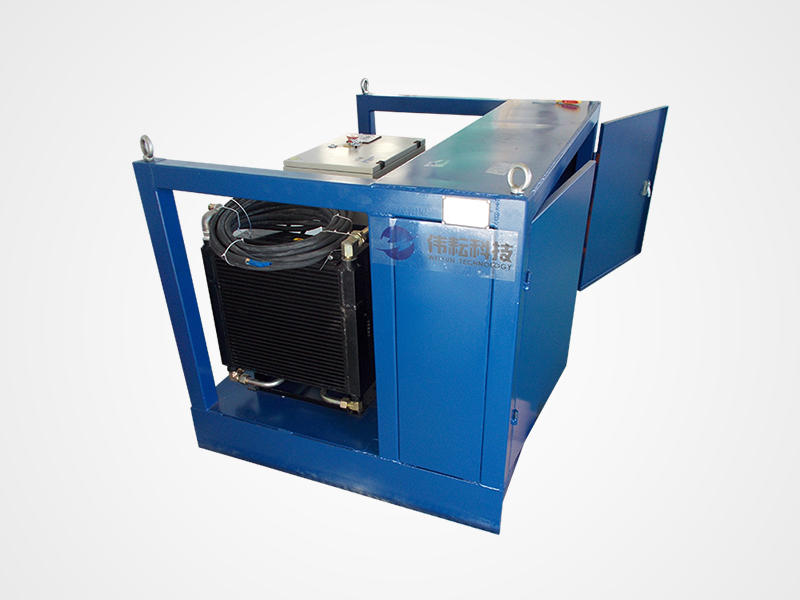

- This unit is equipped with high pressure water pump and high pressure air pump.

- The highest theoretical output pressure of air pressure and water pressure is 450bar.

- The valve test console is mainly used for setting and recording pressure test parameters.

- The vertical valve test stand is mainly used for pressure test of small-sized safety valves.

- This equipment is divided into three parts: horizontal valve test stand, vertical valve test stand and valve test console.

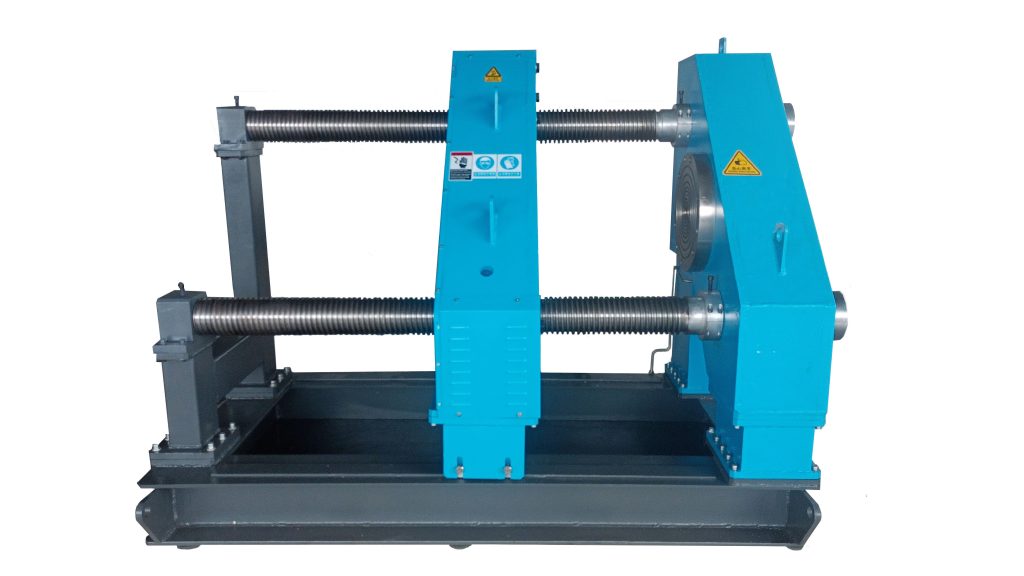

- The horizontal valve test stand is mainly used for pressure test of large-sized through valves, and can perform hydraulic and air tightness tests on valves.

| Horizontal Valve Test Stand (mm) | 2200L*1450W*1550H |

| Vertical Valve Test Stand (mm) | 650L*650W*1000H |

| Valve Test Console (mm) | 1250L*700W*1400H |

| Ambient temperature | -10 to 50℃ |

| Test medium | Natural water (recyclable), nitrogen (non-recyclable) |

| Air source inlet | φ12 PU quick connector |

| High pressure outlet | G3/8” |

| Air-driven pressure | ≤10bar |

Horizontal Valve Test Stand

| Test pressure | 1 to 38Mpa |

| Inner diameter of test valve (mm) | DN80-DN300 |

| Maximum length of test valve | 1m |

| Bearing tension of the equipment frame | 150T |

Vertical Valve Test Stand

| Test pressure | 1 to 45Mpa |

| Valve connection size | G1/2 |

| Adapter tool size | 1/2”NPT, 3/4”NPT, 1”NPT |

Pressure Gauge Calibrator

| Maximum Working Pressure | 700 bar / 70Mpa |

| Pressure gauge accuracy | 0 to 16Mpa: 0.05%FS |

| Pressure gauge accuracy | 0 to 100Mpa: 0.05%FS |

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————