Helium gas casing and tubing thread seal test equipments

- The purpose of helium gas testing is to detect even the slightest leak or imperfection in the thread seal, which could lead to catastrophic consequences if left undetected. By using helium, a lighter-than-air gas, the testing process becomes more sensitive and accurate, allowing operators to identify potential issues before they become major problems.

Share to

Overview

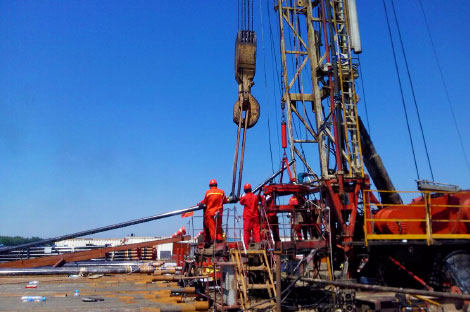

The continuously popularized technology for the development and exploitation of deep wells and horizontal wells and the large-scale development of gas has raised the higher requirements for tightness of tubing and casing; to minimize the potential safety risk of incidents caused by thread leak, special-thread casing, and tubing are mandatorily required for leak detection in most oilfields in Asia, North America, Mexico, and South America.

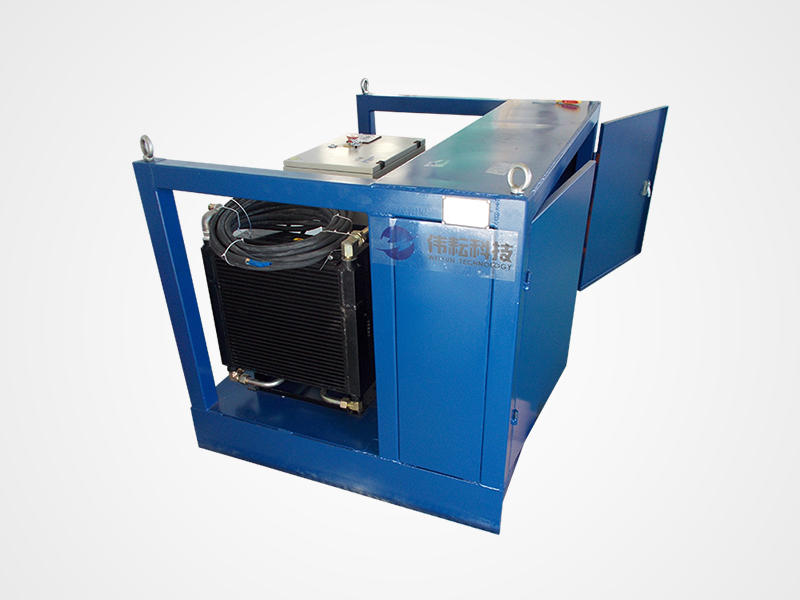

This tubings and casings thread leakage detection equipment use high pressure to increase the mixture of helium & nitrogen to the testing pressure. The dual seal detection packer is delivered to the thread connection of strings when strings are put down into the hole, then it is set to seal. Lately, the high-pressure helium is injected into the packer tool and high sensitivity detector works outside of the tubing thread and takes the advantage of the small size of the helium molecule & easier to escape, to test the air tightness of connections of the tubings & casings.

Helium Leakage Detection Characteristic

- Sensitivity: reach the rates of 1*10-7Bar·ml/sec helium.

- Reliability: easy to penetrate from gas seal thread and to detect due to mini helium molecular.

- Safety: detection gas helium is a kind of inert gas, lighter than air and not corrosive and damages tested objects and operators.

- Convenience and efficiency: detection operation is rapid and 2 minutes for a piece of tubing on average, so no influence on well completion.

- Wide Application: 2-3/8″, 2-7/8″, 3-1/2″, 4-1/2″, 5″, 5-1/2”, 7″; FOX, BGT, VAM thread casing and tubing; Christmas tree stand, pipeline, etc.

- Long service period: Our WY-QY70 seal packer has new patent designs in a steel cylinder and rubber, seals quickly and reliably, and can be used continuously under 70Mpa(10000psi) for more than 300 times.

Case

| Ambient temperature | -15 to 70℃ |

| Operational environment | Onshore O & G field, offshore platform O & G field; wet, salty mist, oil mist |

| Test medium | Helium gas (40L & 50Mpa cylinder) |

| Test pressure class | 1st boost 25Mpa, 2nd boost 70Mpa |

| Drive mode | Air or hydraulic oil |

| Structure | Skid-mounted |

| Protection class | IP54 |

| Explosive proof class | ExdIIBT4 |

| Approval | BV, DNV, or CCS by customer’s requirement |

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————