Overview

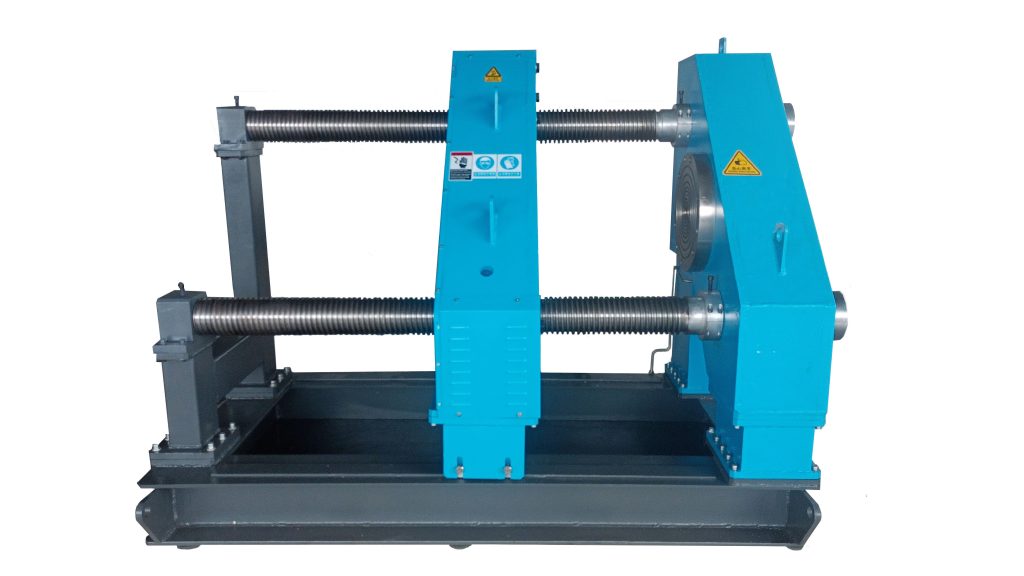

This Vertical Valve Test Bench integrates electromechanical, hydraulic, and pressure testing liquid medium storage and circulation, with the characteristics of complete functionality, stable performance, and high degree of automation. The entire process of pressure testing is controlled by hydraulic transmission and electrical appliances, and external forces are applied to the tested valve without any additional impact on the test results. It is widely used in straight through flange structures with a nominal diameter of DN15-DN300mm, as well as sealing and strength testing of valves such as high, medium, and low pressure gate valves, ball valves, globe valves, check valves, and plug valves.

FAQ

| ① Driving air source pressure is too low (Driving Air Source Pressure * Boost Ratio = High-Pressure Outlet Pressure) | a. Check whether the driving air pressure reaches the rated value. b. Listen for air leaks or abnormal noises in the air loop. c. Adjust the driving air pressure to the required value. |

| ② Filter—Pressure Regulator Component Failure | Check if the pressure regulator filter is blocked or if there is water accumulation. |

| ③ Abnormal clamping device operation | Check whether the front, rear and lifting pipelines of each clamping jaw are connected correctly. |

| ④ Insufficient hydraulic system pressure | Check whether the oil tank level meets the requirements. |

| ⑤ The throttle valve of the clamping jaw’s actuating cylinder is too tight. | Gradually loosen the throttle valve while conducting operational tests to verify performance until the hydraulic cylinder jaws resume smooth and stable operation. |

Model: WY-380AW-TJ1

- Test media: water, gas, oil. The maximum sealing test pressure is 25MPa, and the strength is 37.5MPa.

- The high and low pressure water pumps are fixed in the front of the test bench to circulate the medium.

- The structure of this unit can be divided into hydraulic system, mechanical system, electrical control system, etc.

- Equipped with the hydraulic pressure supply device, the low-pressure water pump and the media circulating tank system and other components.

- The pressure gauges, water control valves and electrical button switches are all designed to be operated and controlled in front of the test bench, which can coordinate the actions of various mechanisms, make operation convenient, safe and reliable, and meet the testing needs of users.

Model: WY-380AW-TJ1

| Test medium | Water (anti-corrosion water), air |

| Applicable valve types | Straight through type: Flange type, threaded type; safety valve |

| Size | 2900L*950W*2300H |

| Working voltage | 380V 50HZ |

| Maximum test pressure | 375 bar / 37.5 Mpa |

| Nominal pressure | 1.6 to 25 MPa |

| Nominal diameter | DN15-300/1”-12” |

| Design negative compression force | 100 T |

| Allowable test valve flange diameter | 15-530 mm |

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————