Explosion-proof Pressure Testbay Box

- Explosion-proof Pressure Testbay Box (PTB) is a type of a pressure test equipment for injection of different media such as clean water and glycol.

- As a kind of customized sectional long test box, our containerized Pressure Testbay Box has been served in chemical, construction, plumbing, petroleum, coal, smelting, shipbuilding and other industries.

- Can be designed to meet your general safety design standards and specific needs.

Share to

Application

- It can replace pressure testing workshops, pits and others as safety protection equipment.

- Suitable for pressure and temperature test of various downhole tools, valves, pressure vessel, cylinder, etc.

Advantage

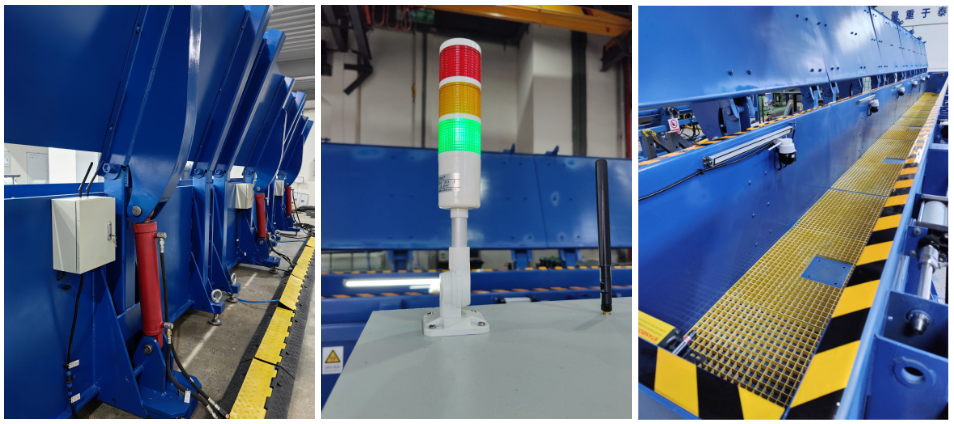

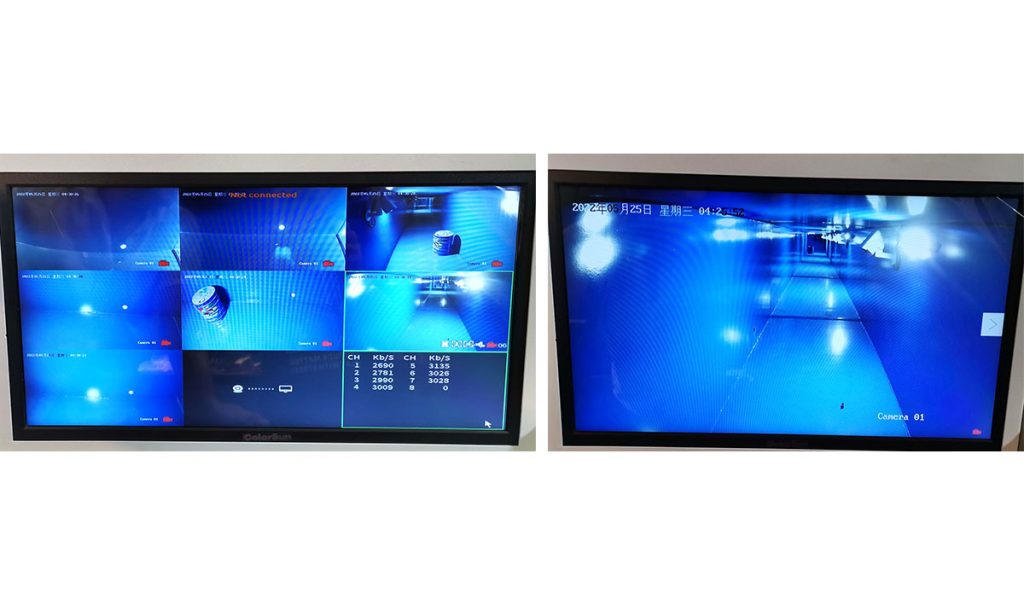

- Installed with the PTZ fixed and movable camera, which can monitor the test workpiece in all directions.

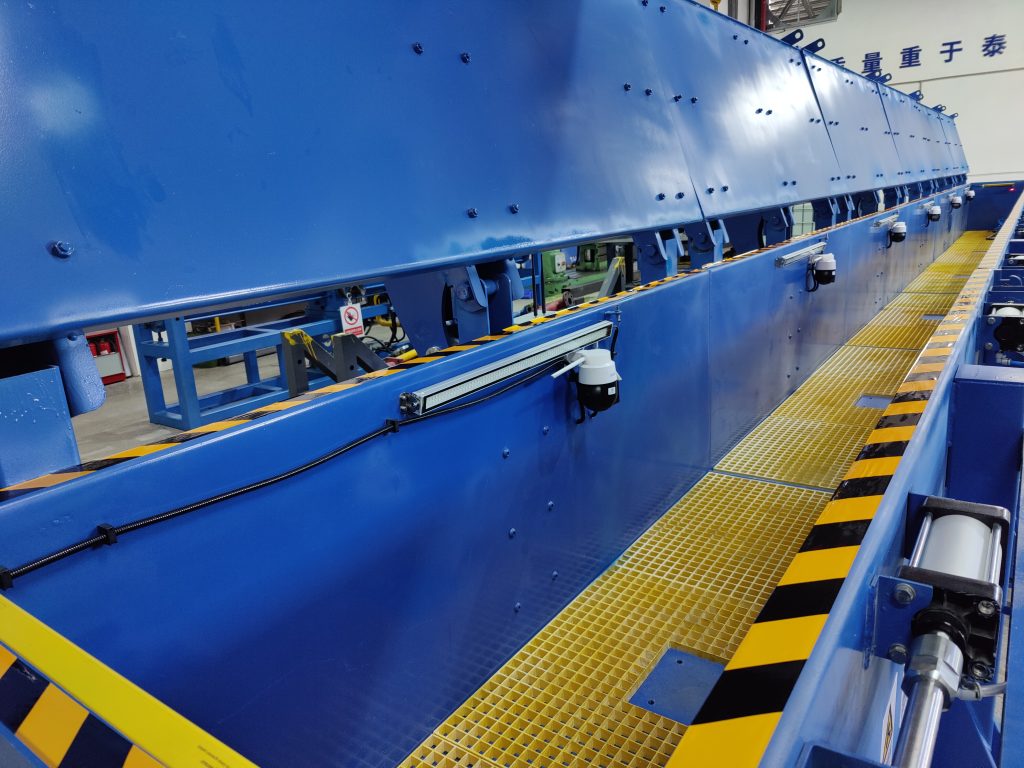

- Multiple sections can be assembled according to the requirements of the test workpiece and connected together with M30 bolts.

- Its modular design and skid-mounted or vehicle-mounted design are adopted to facilitate equipment transfer and on-site operation.

- Equipped with the self-locking switch to prevent danger caused by people or foreign objects near the testbay box door during testing.

- Due to its unique modular structure, it can be assembled according to the actual needs to adapt to different test workpiece requirements.

- High strength protective wall is made of steel plate, bulletproof fiber, interlayers and other comprehensive materials, with a thickness of 70 mm.

Features

- The unit has the function of boosting clean water and glycol.

- Install the necessary safety valves and pressure control components.

- Remote PTZ video monitoring system to observe the on-site conditions and safety.

- Compressed air unit and pressure test unit are designed separately for ease of use.

- The control panel of the pressurization unit adopts a modular design, and the operation process is clear.

- Equipped with high-strength pressure test protection cabin, which can carry out explosion-proof safety prevention and control of high-pressure test.

- Equipped with automated functions such as digital remote control, real-time data display, monitoring, generating experimental reports, and querying historical data.

1. Pressure Testbay Box

| Working pressure | 1000 bar / 15,000 psi |

| Size | 18m*2m*1.5m (single section: 3m*2m*1.5m) |

| Weight | 12.7 T (single section: 2.1 T) |

| Thickness | 70mm (10+50+10) |

| Number of cameras | 6 adjustable cameras with night vision function |

| Lighting | 24V/100W led, quantity: 6 |

| Door opening mode | Hydraulic cylinder telescopic opening |

| Door opening direction | Upward (angle greater than 90°) |

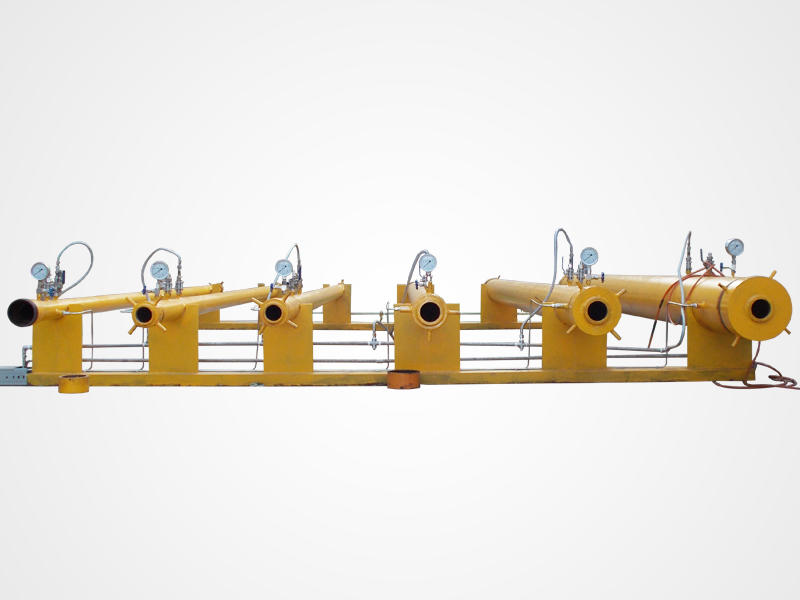

2. HPU

| Max working pressure | 1000 bar / 15,000 PSI |

| Working voltage | 380V 50HZ |

| Working medium | Water & Glycol |

| Water high pressure outlet | G1/4-60° |

| Water inlet | NPT1/2” |

| Air-driven interface | NPT1/2” |

| Cylinder outlet A and B | φ8mm |

3. Pre-fill Station

| Volume | 1000L |

| Material | HDPE |

| Water outlets | 2*NPT1”(F) |

| Outlet filtration | 40 μm |

| Size | 1500*1300*1400mm |

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————