Non-Marking Die Tooth Power Tong

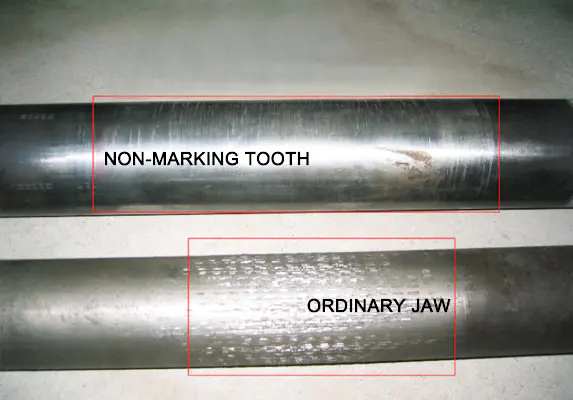

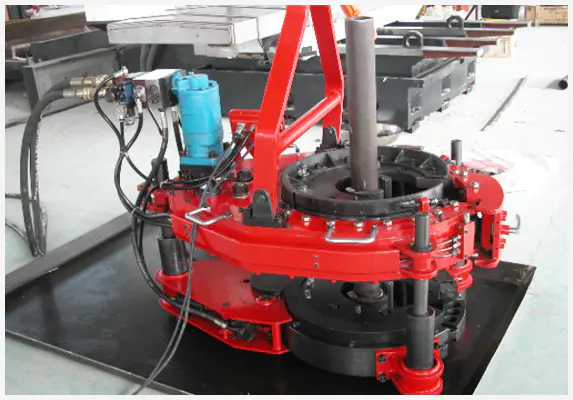

- This is a specialized type of tong designed for efficient and damage-free handling of delicate materials in various industrial settings. This heavy-duty tool is engineered to provide unparalleled gripping power without leaving unsightly marks or scratches on the surface of the materials being manipulate.

Share to

Overview

Large, the contact surface is large, the friction is strong, the oil pipe is not damaged and not deformed, especially suitable for tubings and casings made of 3CRr, 22Cr and 13Cr materials.

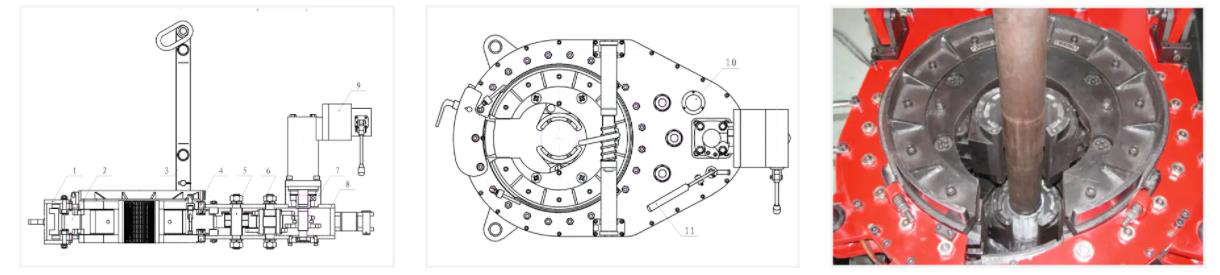

- The safety door is operated by mechanical control, which is simple, safe, more stable and convenient.

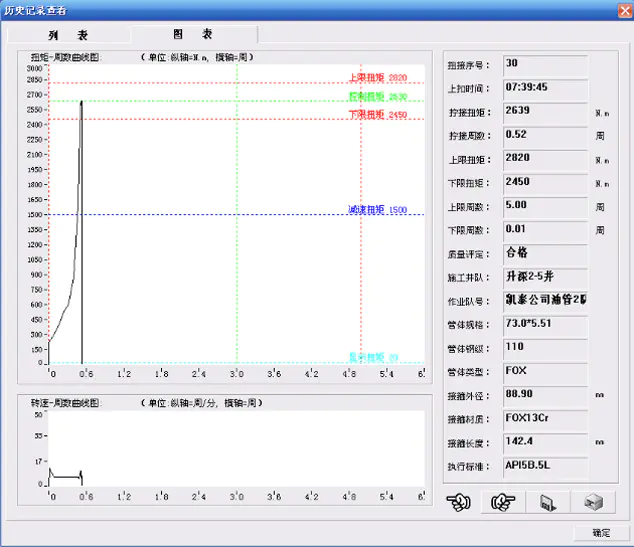

- The automatic torque control system has high precision in torque value setting, control, storage and printing.

- Fully hydraulically driven, the maximum torque can reach 50,000N.m, and it can hold the oil pipe with the diameter of up to 5″.

- When the shackle is shackled, the back tongs will float in parallel with the main tongs, and the centering will be automatically centered to avoid the adverse effects caused by the main back tongs unbalanced to the thread and avoid the phenomenon of sticking.

- The new toothless tooth is made of special plastic material. It does not slip and does not damage the oil pipe. The primary protective film holds at least 30 oil pipes. Even if it is slippery due to the tightness of the clamp, it will not hurt the oil pipe surface.

- Adopting two-plate type full-cohesion clamping mechanism, different specifications of the tubing body and coupling are equipped with corresponding curved arc plates, the surface of the tubing clamped is absolutely free of tooth marks, no stress concentration phenomenon, avoiding underground Secondary accident.

Portable Torque Meter (WY-12) Features

Interface

Main Technical Parameters

| Supply voltage | 220V AC |

| Power supply frequency | 50 HZ |

| Working voltage | 24V DC |

| Power consumption | ≤200W |

| Measurement and control accuracy | ≤1% |

| Ambient temperature | -40°C to 60°C |

| Ambient humidity | ≤80% |

Scope

| Model | Range(kN.m) |

| NY6 | 6 |

| NY12 | 12 |

| NY15 | 15 |

| NY35 | 35 |

| NY50 | 50 |

| NY100 | 100 |

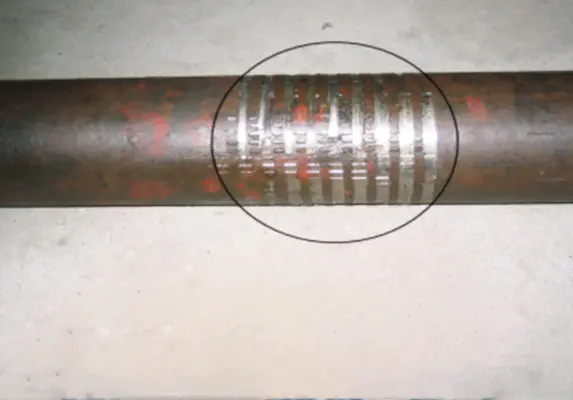

The tubing body that is clamped by ordinary teeth die andthe block is slipped

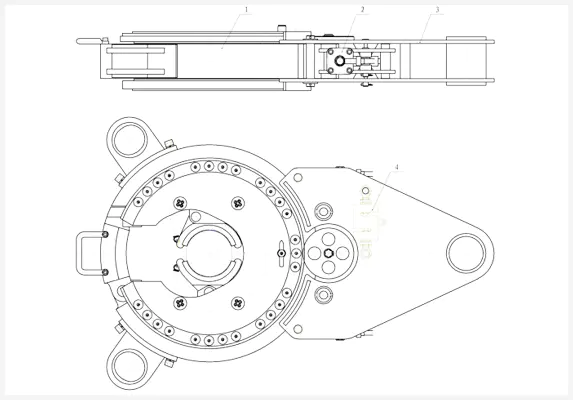

Main Forceps

| Item | Model | Drawing No. | Description | Qty |

| 1 | MXQ140-11 | MXQ140/12Y.1.4 | Safety door assembly | 1 |

| 2 | MXQ140-12 | MXQ140/12Y.1.2 | Clamp head assembly | 1 |

| 3 | MXQ140-13 | MXQ140/12Y.1.5 | Suspension rod assembly | 1 |

| 4 | MXQ140-14 | MXQ140/12Y.1.3 | Brake belt | 1 |

| 5 | MXQ140-15 | MXQ140/12Y.1.6 | Wheel assembly | 2 |

| 6 | MXQ140-16 | MXQ140/12Y.1.7 | Triple gear assembly | 1 |

| 7 | MXQ140-17 | MXQ140/12Y.1.8 | Input shaft assembly | 1 |

| 8 | MXQ140-18 | MXQ140/12Y.1.1 | Housing assembly | 1 |

| 9 | MXQ140-19 | MXQ140/12Y.1.10 | >Control valve group | 1 |

| 10 | MXQ140-20 | NY12 | Torque control assembly | 1 |

| 11 | MXQ140-21 | XQ140/12YD.1.9 | Hanging gear assembly | 1 |

Back Clamp

| Item | Model | Drawing No. | Description | Qty |

| 1 | MXQ140-221 | MXQ140/12Y.2.1 | Back clamp head assembly | 1 |

| 2 | MXQ140-222 | MXQ140/12Y.2..2 | Back tong tail assembly | 1 |

| 3 | MXQ140-223 | MXQ140/12Y.2.3 | Bracket assembly | 1 |

| 4 | MXQ140-224 | MXQ140/12Y.2.4 | Load cell assembly | 1 |

Power Tong (MXQ140/12Y)

| Applicable pipe diameter range | |

| Main pliers | Ф73-140(27/8″ – 51/2″ tubing, casing) |

| Back tongs | Ф89-153.7(27/8″ – 51/2″ tubing, casing coupling) |

| Clamp head speed | |

| Fast file | 25 rpm |

| Slow | 10 rpm |

| Maximum torque | |

| Fast file | 6.1 kN.m |

| Slow file | 14.9 kN.m |

| Rated pressure | 14 MPa |

| Rated flow rate | 120 L/min |

| Dimensions | 1300*750*1100 mm (length*width*height) |

| Weight | 1080 kg |

Torque Meter (NKY-Y153)

| Power supply voltage | 220V AC ±15% 50 to 60HZ |

| Power consumption | 200W Max. |

| Range | 15200N.m |

| Control range | Can be set |

| Unloading discharge | 80L/min |

| Size | Laptop 340*280*38MM Power signal converter 210*75*270MM Torque display 148*126*48MM Packing volume 600*450*320MM |

| Weight | 45KG |

Hydraulic Power Unit (JZYD160)

| Max oil supply pressure | 200 bar / 20Mpa |

| Rated oil supply pressure | 8Mpa/20Mpa |

| Flow rate | 30 to 160L/min |

| Motor power | 30Kw |

| Oil pump model | 25/80YCY14-1B |

| Capacity | 500L |

| Cooler model | AH1490-cd2 |

| Dimension | 1880*1250*1350mm |

| Weight | 1300Kg |

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————