Overview

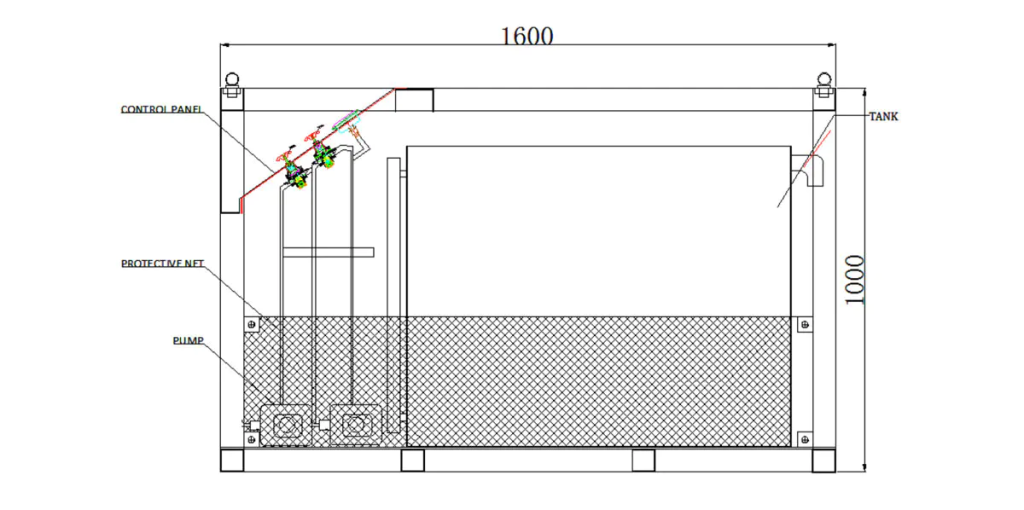

This‘s a pressure test equipment with a liquid storage tank and a mechanical recorder. It’s equipped with a 1000L liquid storage tank and uses compressed air as a power source to quickly press the detection medium and record pressure in real time.

Pressure testing involves subjecting a pipeline section to a predetermined pressure exceeding the anticipated operational pressure. This controlled pressure increase allows engineers to identify any potential weaknesses, leaks, or defects in the pipeline’s material or construction. The duration of the test and the specific pressure profile depend on the pipeline’s design, material, and intended application. A critical component of this process is the accurate and continuous monitoring of pressure changes, which is where chart recorder prove invaluable.

Feature

- A flow chart of the boosting process is etched onto the control panel surface of the booster unit.

- The uniquely designed rope-retractor structure ensures the pipeline coils neatly while also enabling preliminary cleaning.

- Additionally, the system is equipped with a large-capacity liquid storage tank, providing sufficient media for on-site operations.

- The system uses an air-driven hydro pump as the boosting unit, featuring a pressure self-locking function to prevent overpressure.

- Equipped with a mechanical recorder, this unit is made from stainless steel to withstand harsh conditions. The electrical component interfaces are housed in an explosion-proof box for safety.

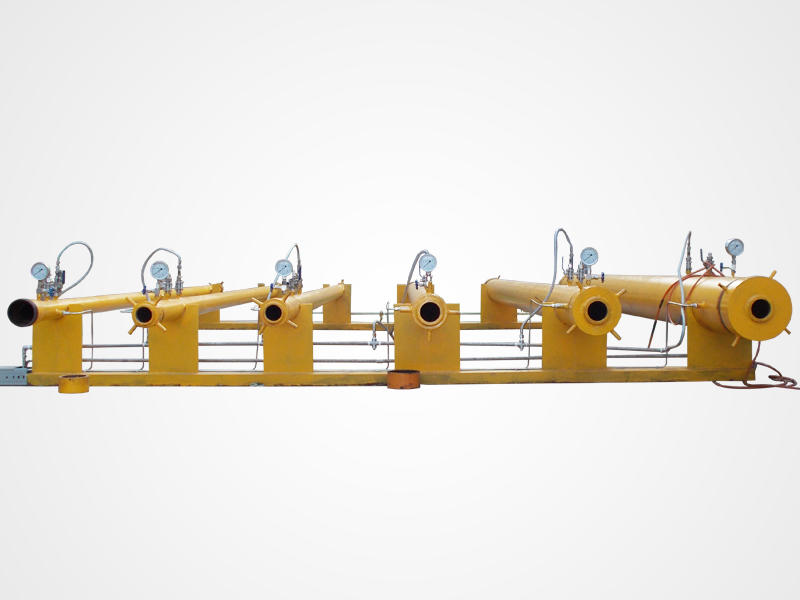

- It includes both a large-displacement low-pressure pump and a small-displacement high-pressure pump, providing precise control over different pressures, flow rates, and compression cycles.

Model: WY-700W-J1