Wellhead Pressure Test Skid

- With its modular design, high-pressure capability, advanced pressure control, and real-time data acquisition, the skid is suitable for a wide range of applications, from well completion and workover operations to well intervention and remediation. By providing a safe and controlled environment for testing wellheads, the Wellhead Pressure Test Skid can help operators improve safety, increase efficiency, and reduce costs.

Share to

Overview

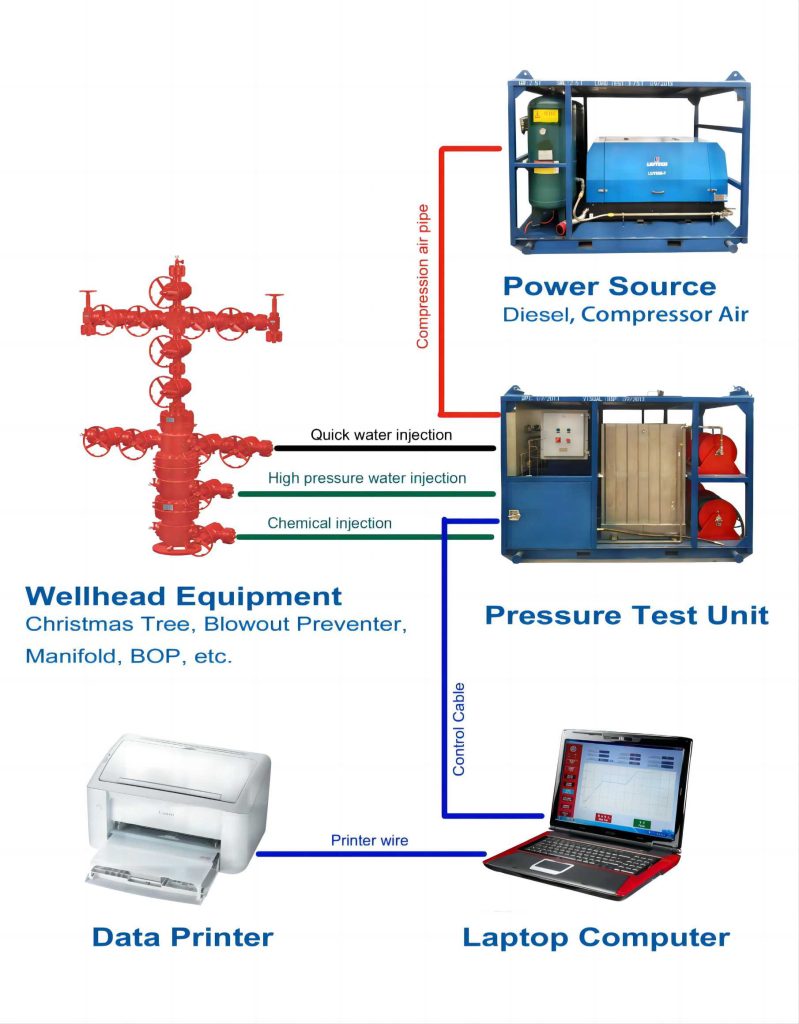

Compressed air supplied by diesel/hydraulic/motor compressor drives pressure booster for making high pressure testing medium. The completed equipment consists of power unit pry and pressure testing unit.

Standard

Characteristic

- Switching between automatic and manual operation.

- Large output flow rate and high pressure test efficiency.

- Remote control system which can ensure safe operation at the site.

- Multiple options of power sources: diesel engine, compressed air, and electric motor.

- All high pressure valves, tubing, and pumps are made in Germany with 316SS to guarantee test precision and stability.

- Equipped with an automatic control system and video monitoring system to meet the needs of operational pressure test requirements.

- Use gas-driven booster pump to finish pressure boosting, and prevent from overcharging phenomenon incur in the other ways of boosting.

Specification

- Pressure control precision: +/-1% FS

- Pressure test medium: clean water, oil and mixed liquor

- Control panel applies modular area design for simple and clear operation.

- Use human-computer operation interface and long distance remote control.

- Configuration software shall record real-time boosting curves and print the results.

- Compact structure and easy operation. Put water tank, high-pressure pipeline, and boost equipment onto an integrated skid.

- The maximum flow rate shall be 48L/min(12.66Gallon/min) while using a low-pressure large flow rate pump for quick charging.

- Selective boosting pressure ranges are achieved quickly by various high-pressure small flow rates, 0 to 25Mpa, 0 to 55Mpa, 0 to 105Mpa, 0 to 160Mpa, 0 to 200Mpa (29000psi).

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————