What do you need to know to avoid accidental gas booster pump operation?

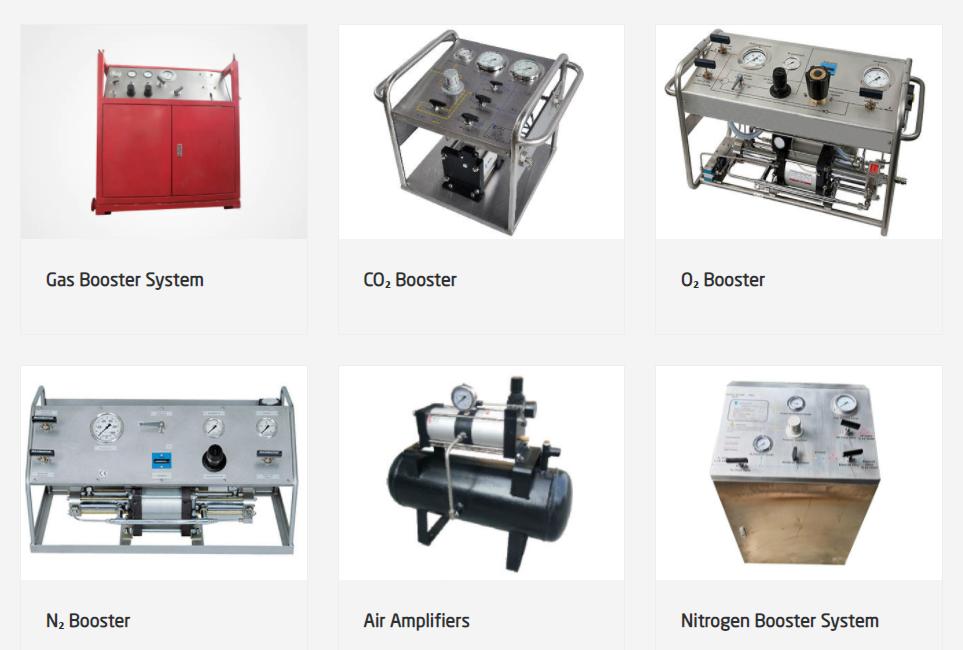

The booster valve can output multiple high-pressure gases, and the role of the gas booster pump is to input it, which can reach 2 times or 5 times the high-pressure gas. Manual adjustment is possible for output pressure and drive, with straightforward operation and excellent practicability. Let’s discuss other needs and how to choose the right gas booster pump.

How to choose the right gas booster pump type

Nitrogen, oxygen, and hydrogen are among the gases that the booster valve can pressurize. When choosing the type, the client should take the initiative to specify the necessary pressure and flow if the gas is corrosive, such as H2S, SO2, etc.

Gas Booster Pump Filtration Requirements

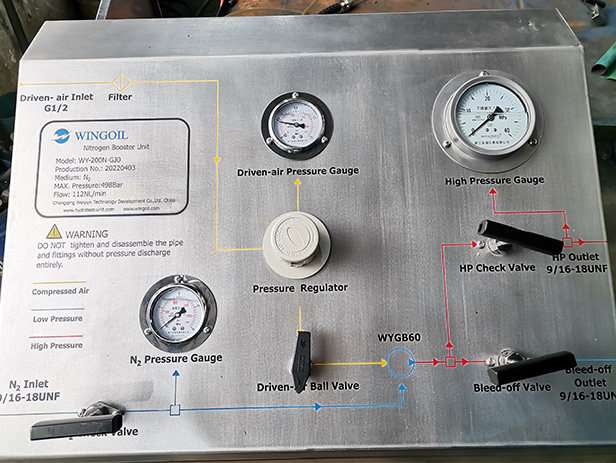

Compression serves as the booster valve’s power source, and it requires clean air and particles smaller than 5 um. The factory’s air source is typically quite polluted. If it is linked to the valve directly without filtering, the pump will build up dirt over time, which will eventually cause the one-way valve to malfunction. The sealing ring has significant wear.

Gas booster pump installation requirements

The driving air source should be installed using a PU air pipe since it is simple to set up and operate and won’t corrode. If the metal pipe is used, it must be compressed before installation in order to prevent welding slag from blowing into the reversing valve and causing it to become stuck. Its service life may be impacted by the driving air source’s medium and purity. Normal compression will include some moisture and contaminants in the absence of a cold dryer or filter. The booster pump’s performance will be hampered by the moisture and pollutants that enter it. Its sealing ring and cylinder will become scratched with usage and efficiency.

Safe operating procedures for gas booster pump

1. The operator must be familiar with the equipment’s general layout and capabilities; using the equipment in any way other than as intended is strongly prohibited.

2. Before the operator, look for air leaks in the air pipe, couplings, and filter.

3. Integrate the air valve and modify the air pressure regulating valve to set the output air pressure to the desired level (tank pressure 0.95Mpa).

4. Check to see if the booster pump can operate normally.

5. Check to see if the gas storage tank’s pressure gauge reaches the preset level and whether the booster pump turns off when it does.

6. After the booster pump stops operating, confirm once more that the regulator’s pressure setting and the tank gauge pressure are in agreement.

7. When the job is done, shut off the air valve and clean the equipment.

Requirements for the use of gas booster pumps

The gas booster pump needs to be used and maintained in a number of ways in order to function better while in use and prevent mishaps.

Gas circuit boosting, pressure maintenance, and pressure stabilization are tasks that gas booster pumps are employed for in various industries. The natural gas industry is one example of a specific industry, which also includes pipeline transportation and pressure and static testing of valves, pipes, cylinders, etc.

When the air pressure needs to be increased because it is insufficient in the hot runner business. testing of brake systems and other parts for leaks in the auto parts industry. Transport via pipeline, instrumentation, and high-pressure gas testing are all related to the petrochemical sector. Additionally, there is the sewage industry, electrical industry, chemical industry, fire prevention industry, industrial robot industry, and so forth.

It is required to set the driving air pressure to between 3 and 8 bar while utilizing the gas booster pump. The driving air pressure’s 6 bar economic use pressure. Additionally, in order to ensure that the driving cylinder and the reversing valve function normally and that the sealing ring lives a long time, the driving air pressure needs to be kept clean, dry, and free of moisture.

A filter is installed at the IN (inlet) pressure of the gas booster pump’s booster section to maintain the purity of the pressured gas medium and serve as secondary protection. In addition, it is advised to install a bursting disc and other safety protection measures if the pressure of the high-pressure outlet is too high. It is important to purchase a pressure vessel (with a pressure vessel certificate) whose pressure value is higher than the rated output pressure of the pump body if the high-pressure outlet needs to be equipped with a buffer tank.

Gas Booster Pump Maintenance Requirements

Before performing maintenance on the gas booster pump, it must be maintained without air pressure, the drive must be stopped, the intake pressure must be stopped, and the high-pressure output pressure must be unloaded. Additionally, it is advised to interact with technical staff or carry out maintenance while being guided by video.