What is a Nitrogen Generator?

In industrial manufacturing, nitrogen as an inert gas is unavoidable. It is utilized to a significant extent in various applications from food packaging, production of electronics, prevention of explosions in chemicals, and oil and gas exploration. Compared to traditional methods of nitrogen supply like bottled nitrogen or liquid nitrogen, a Nitrogen Generator cleans nitrogen from the air directly, which promotes on-site production, on-site consumption, and cost-saving.

So, what is a nitrogen generator? What is used for? In this post, we will provide you with detailed answers.

Part 1. What is a Nitrogen Generator?

A nitrogen generator is a machine that extracts nitrogen from compressed air. Unlike traditional methods via high-pressure nitrogen cylinders or liquid nitrogen storage, it generates pure nitrogen directly from the ambient air through advanced technologies, with continuous supply to industrial systems.

Two main kinds of nitrogen generators are in common use:

PSA (Pressure Swing Adsorption) Nitrogen Generator:

This process uses Carbon Molecular Sieves (CMS) to separate gases based on differential adsorption characteristics with pressure.

Membrane Nitrogen Generator:

It utilizes hollow fiber membranes to separate gases based on the differential rates of gas molecule diffusion. Faster gases like oxygen and water vapor diffuse through the membrane walls at a greater rate, with rejection of nitrogen.

Both processes are capable of producing nitrogen with purity levels greater than 99% and can be configured to meet individual industrial requirements.

Part 2. Key Advantages of Nitrogen Generators

Compared to traditional means of nitrogen supply such as bottled gas or liquid nitrogen supply, nitrogen generators possess some important advantages that render them the first choice for application in most industries:

Lower Operating Costs

One of the greatest benefits is cost savings. Nitrogen generators eliminate routine bottling plant buys of packaged nitrogen or liquid nitrogen shipments. Using on-site nitrogen from the surrounding air, companies can avoid huge transportation, storage, and rental expenses, experiencing a reduced cost of ownership in the long run.

Increased Operational Efficiency

With on-site nitrogen generation, there is continuous and instant supply. There are no refills required, nor is there any lacking gas in the middle of the operation. This offers uninterrupted flow, saves time for downtime, and maximizes overall productivity, especially in continuous supply of nitrogen operations.

Better Safety

Explosion and gas leakage risk is associated with storage and handling of liquid nitrogen or high-pressure gas cylinders. Nitrogen generators minimize these risks by avoiding cylinder handling and lowering pressure levels of nitrogen supply, resulting in improved workplace safety and conformance to regulations.

Improved Control and Flexibility

Advanced nitrogen generators are already equipped with smart controls and monitoring systems. It is simple to adjust nitrogen flow rates and purity levels to meet immediate operating conditions. This flexibility enhances precise integration into automated industrial processes and enhances the flexibility of the production system.

Part 3. Application of Nitrogen Generators

Nitrogen generators are used extensively in almost all industries requiring a continuous and pure supply of nitrogen. Prominent application areas are:

Food Industry

Nitrogen has uses in modified atmosphere packaging (MAP) for replacing oxygen, thereby slowing down oxidation as well as microbe growth. This extends the shelf life of short-lived products such as snacks, coffee, dairy, as well as meat.

Electronics Manufacturing

In semiconductor and circuit board production, nitrogen provides an inert atmosphere while assembling and soldering, preventing oxidation and preserving the integrity of sensitive components.

Pharmaceutical Industry

Nitrogen covers sensitive active pharmaceutical ingredients (APIs) against oxidation during shipping and storage. It further purges pipelines and containers to provide product quality and safety.

Chemical Industry

Nitrogen is utilized as a blanketing gas to protect volatile or flammable chemicals, and it is also utilized in purging, pressure transfer, and inerting operations, avoiding the possibility of contamination or combustion.

Oil and Gas Industry

As one of the fastest-growing application markets, the oil and gas industry relies extensively on nitrogen for well stimulation, inerting flammable atmospheres, pressure testing, enhanced oil recovery, and purging pipelines. On-site nitrogen generation in the industry increases safety, reduces logistics, and offers continuous operation within remote or offshore locations.

Part 4. Key Role of Nitrogen Generators in the Oil and Gas Industry

Nitrogen plays a crucial role in enhancing the safety, efficiency, and productivity of the oil and gas industry. It is used extensively in the following applications:

Pipeline Purging and Drying

Nitrogen is used to push out oxygen and water from pipelines before injecting hydrocarbons and reduce the chance of combustion and corrosion.

Well Stimulation and Enhanced Recovery

Nitrogen is injected during drilling and production to increase reservoir pressure or evacuate wellbore liquids to increase oil and gas flow rates.

Tank Inerting

When nitrogen is pumped into storage tanks, oxygen levels are minimized, significantly reducing the explosion or fire hazard when storing combustible materials.

Leak Detection and Pressure Testing

Nitrogen is used as an inert, non-poisonous test gas to detect leaks and verify pipeline, valve, and other equipment integrity.

Increased Drilling and Production Safety

Maintaining an inert gas environment about fragile instruments avoids the accident from taking place by preventing gas combustion or contact with air.

Traditional nitrogen supply systems in the form of bottled gas or liquid nitrogen are usually not cost-effective in distant oilfields or offshore platforms due to high transportation costs, logistics challenges, and safety risks.

Nitrogen generator container unit, on the other hand, offers a compact, portable, and cost-effective solution. They deliver clean, uninterrupted nitrogen at or near the point of use, which makes a significant difference in operational reliability and safety in hostile oil and gas environments.

Part 5. Nitrogen Generator Container Unit: Specialized Solution for Oil & Gas

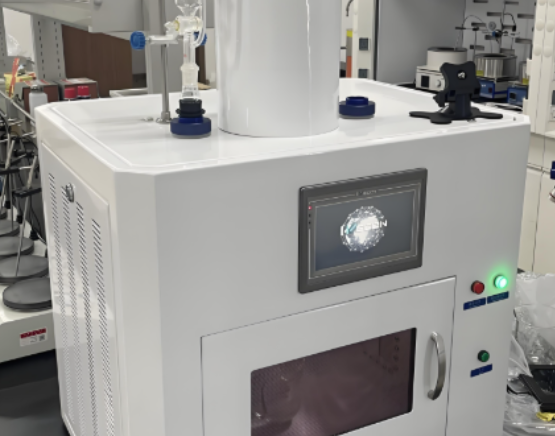

To meet the needs of remote, hostile, and high-hazardous environments of oilfield operations, our Nitrogen Generator Container Unit is an integrated on-site nitrogen supply solution. Developed exclusively for the oil and gas industry, this portable unit has all the components needed in a rugged container and offers reliability as well as flexibility when put into the field.

All-in-One Design

The unit houses an air compressor, air treatment system, PSA nitrogen generator, and control panel in a weatherproof casing. The unit is delivered fully assembled and plug-and-play capable for installation, reducing set-up time and effort significantly.

Easy Transportation and Fast Deployment

Linked to a standard shipping container, the system is land and offshore transport optimized. It is quick to deploy to drilling sites, oilfields, and offshore installations, where traditional nitrogen delivery equipment is hindered or impractical.

Durable and Field-Proven

With heavy-duty equipment, the generator is built for safe operation in harsh conditions like heat, dust, humidity, and corrosive atmospheres, providing around-the-clock service in the most demanding oilfield environments.

Intelligent Automation

The machine features a PLC-based automatic control system, remote monitoring, and parameter-adjustability, enabling it to operate stably with minimal manual operation and enhanced operational safety.

Advanced Performance Features

- Nitrogen purity up to 99.99%

- Infinitely variable output pressure and flow rate

- Static pressure holding with zero energy consumption at target pressure

- Integrated nitrogen booster for high-pressure applications

- Compact structure and user-friendly interface

Thanks to its portability, efficiency, and field-designed concept, this Containerized Nitrogen Generator Unit is today the preferred option for the majority of oil and gas companies looking to enhance operational autonomy, reduce expenses, and improve safety.

Conclusion: Why Choose Nitrogen Generator Container Units?

Understanding what a nitrogen generator is and where it is located enables companies to make smarter and cost-effective decisions. Especially in the oil and gas industry, choosing an effective containerized nitrogen generator not only reduces the cost of operation but also enhances safety and response time for projects.

For solution of nitrogen generator container units of gas and oilfield, if interested, please feel free to contact Wingoil for technical consultation and customized solution.