What is Multiphase Pumping System and How Does It Work?

In the new oil and gas industry, oil, gas, and water mixture transportation without separation has become a key strategy for cost reduction and efficiency improvement. Here’s where the new-fangled multiphase pumping system comes into play, which was developed to meet the need.

In this article, we will provide you with a detailed introduction to its definition, operation, key components, application areas, advantages, and disadvantages, so that you can make your own judgment whether the technology is applicable for your project or not.

Part 1. What is Multiphase Pumping Technology?

Multiphase pumping technology refers to the use of special pump equipment to inject a multiphase mixture of oil, natural gas, water, and even solid particles directly from the wellhead to processing or gathering plants without having to go through intermediate separation. It deviates from the typical “separate first, then transport” system, significantly simplifying the process of oil and gas production.

This technology minimises operations by eliminating initial separation units as well as reducing the number of surface facilities which, in turn, reduces capital and operating expenses and maximises overall field development flexibility.

The value of multiphase pumping is most evident in subsea oil production, remote onshore oil fields, shale gas development, and marginal field production where streamlined transport is crucial. This technology helps producers extend the economic life of mature fields, access previously uneconomic reserves, and economically and scalably produce complex reservoirs.

Part 2. How Does Multiphase Pumping System Work?

The multiphase pump is the most critical part of a multiphase pumping system, specifically an extremely robust pump capable of pumping oil and gas mixes, water, and solid particles such as sand. The pumps are optimized to be reliable across multiple flow regimes and volumes of gas (GVFs), which makes them suitable for unprocessed well streams.

Following is a closer look at the typical working process:

Inlet of the Multiphase Mixture:

The unseparated production fluid, which is a mixture of crude oil, natural gas, formation water, and possibly sand, goes directly from the wellhead into the multiphase pump with no prior pre-separation.

Compression and Pressure Boosting Within the Pump:

Inside the pump, the blend is compressed through one of various pump designs, usually:

- Twin-screw pumps – most suited for high gas content and gentle shear-sensitive fluid management;

- Centrifugal pumps – cost-effective for higher flow rates with modest GVFs;

- Positive displacement pumps – suitable for longer flow and high-viscosity fluid.

Long-Distance Multiphase Flow Transportation:

Following pressurization, the multiphase fluid is transported through a pipeline to a central processing plant or separator that is kilometers away from the well site or onshore from offshore facilities.

Throughout this operation, no phase division is required at the onset at the wellsite, and this significantly simplifies surface infrastructure needs, reduces equipment footprint, and reduces maintenance. Additionally, by maintaining pressure and minimizing fluid handling processes, the system becomes more reliable and maintains production fluids in continuous flow, making it smooth and efficient even in remote or subsea conditions.

Part 3. Core Components of a Multiphase Pumping System

A full multiphase pumping system is a very sophisticated integration of electronic and mechanical equipment, designed to handle raw and multicomponent fluid in hostile field conditions. The system is typically comprised of the following key elements:

Multiphase Pump (Core Equipment):

This is the core element that presses and transports the raw mixture. Typical examples include:

- Twin-screw pumps: Suitable for high gas content fractions and sensitive fluids due to their low-shear operation;

- Positive displacement pumps: Well-suited to viscous or varying-rate flows;

- Centrifugal pumps: Well-suited to high-capacity use with relatively uniform compositions.

Drive Unit:

The pump is powered by a natural gas motor or electric motor depending on the site condition and availability of power. The drive must be variable speed in order to accommodate fluctuating flow rates and combinations of fluids.

Intelligent Control System:

These advanced control units manage flow rate, pressure, temperature, and gas-liquid ratio in real-time. The systems typically comprise programmable logic controllers (PLCs) and human-machine interfaces (HMIs) for optimal performance and stable and safe operation in varying well conditions.

Monitoring Sensors:

An array of sensors monitors the multiphase flow mixture, pump status, and pipe integrity. Key parameters include gas volume fraction, temperature, vibration, pressure, and velocity of flow, which support operators in predictive maintenance and optimization of the system.

Auxiliary Systems:

These supporting systems are vital to maintain operational stability and protect equipment. These include:

- Lubrication systems for reducing friction and wear in moving parts;

- Cooling systems to manage thermal loads during high-pressure operation;

- Discharge pressure control valves to provide safe and stable outlet pressure.

These are all components of an integrated system that is capable of reliably transporting high-pressure, high-velocity multiphase fluids long distances through complex terrain with low downtime and operational risk.

Part 4. Main Application Areas of Multiphase Pumping Systems

Multiphase pumping systems have been very efficient in numerous challenging industrial applications where conventional separation and transport methods are impractical or excessively costly. Technology is especially valuable in the following areas of application:

Subsea Oil and Gas Production

Multiphase pumps can transfer raw production fluids from subsea wellheads to surface facilities or floating platforms directly. This lowers the need for costly subsea separation stations or intermediate platforms, subsequently reducing complexity and capital expenditure in deepwater ventures.

Remote or Mountainous Onshore Fields

In isolated geologically contained regions or hill country where large-scale infrastructure is not economically feasible to construct, multiphase pumping is an economic alternative. It minimizes the requirement for multiple pipelines or in-field separators so it can be easier to exploit small or scattered reservoirs that are remotely located.

Shale Gas and Tight Oil Fields

Unconventional reservoirs like shale and tight formation usually have high gas volume fraction fluids and severe pressure fluctuations. Multiphase pumping systems are well positioned to address these dynamic fluid conditions, enabling effective transportation from well pads to central processing units.

Mature Field Revitalization

As old conventional oilfields lose their production volume and accumulate gas content, multiphase pumps help maximize artificial lift strategies, maintain flow in low-pressure wells, and enhance the productive age of the field by providing continuous use of existing infrastructure with little change.

Part 5. Benefits of Multiphase Pumping System

Operational and economic advantages are obtained from the implementation of a multiphase pumping system in the oil and gas industry:

Lower Infrastructure Costs:

By eliminating the requirement for early-phase separators, heater treaters, and multiple flowlines for oil, gas, and water, operators can reduce capital and installation costs by a significant amount.

Improved Operational Efficiency:

Raw fluids are constantly pumped which greatly reduces system outages and maintenance caused by blockages, flow instability, gas locking, and other flow interruption issues.

High Flexibility:

These systems will be able to handle a wide range of fluid viscosities, gas-to-liquid ratios, and temperature conditions, making them suitable for application across various types of reservoirs and production conditions.

Increased Well Life:

By effectively managing backpressure at the wellhead, multiphase pumps facilitate maximization of drawdown, improvement of recovery rates, and delaying water or gas breakthrough issues, all with a view to increased well productivity.

Reduced Environmental Impact:

Streamlined surface pump designs result in reduced land usage, reduced emissions, and reduced environmental impact—particularly important in environmentally sensitive or regulated environments.

Multiphase pump technology is a robust, expandable, and progressive solution for today’s oil and gas production demands.

Part 6. Challenges and Limitations of Multiphase Pumping Systems

While multiphase pumping systems are highly cost-effective, flexible, and minimization-advantaged in terms of infrastructure, their usage in real oil and gas projects still comes with some technical and operational demerits. An understanding of these shortcomings is thus crucial for effective decision-making for the incorporation of the system.

Equipment Wear and Tear

Wear on the pump is one of the biggest issues, particularly in the case of abrasive products such as sand or other suspended solids in the flow. Such particles have the tendency to erode internal surfaces like rotors, casings, and seals over time, leading to increased maintenance frequency, unforeseen downtime, and the implementation of robust, wear-durable materials.

Unstable Fluid Properties

The multiphase flow has a direct relation to quick changes in the gas-to-liquid ratio (GLR), flow rate, and pressure. All of these are detrimental to the functioning of the pump, and can cause cavitation or gas locking. Advanced diagnostics and real-time monitoring of all the parameters are necessary to adjust the multi-tier control systems, or else these threats can occur.

High Initial Investment

While savings in the long term may be appealing, the initial capital put into smart pumps with smart controls is a lot more when compared to the conventional systems. With the addition of installation costs, small operators, and operators working at marginal field developments, this can pose a serious problem.

Complex Maintenance and Skill Requirements

With smart systems comes the need for highly skilled field personnel. Advanced maintenance entails knowing more about multiphase flow, and is trained in advanced diagnostics and troubleshooting. Without proper knowledge and support, small problems accumulate, reducing system reliability.

Against such challenges, the installation of a multi-stage pumping system requires objective consideration of the operational conditions of the project, the fluid properties, available technical expertise on site, and long-term economic goals. In the case of uncertain flow composition or sand production areas, the design of the system must include additional protective elements like sand separators, wear-resistant materials, or advanced sensors.

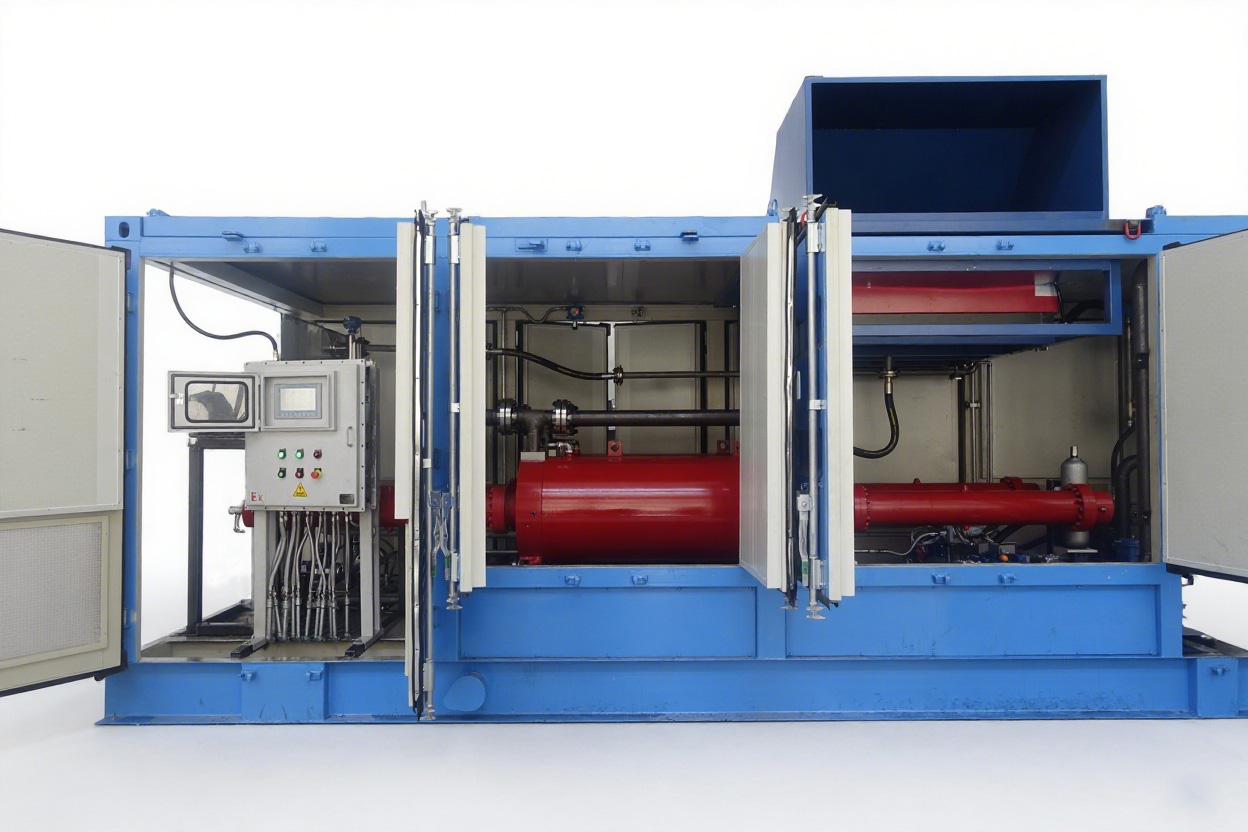

Part 7. Most Efficient Multiphase Pump System – Wingoil Hydraulic Multiphase Transfer Pump System

Wingoil Hydraulic Multiphase Transfer Pump System is a cost-effective and intelligent option to transfer oil, gas, water, and solids directly from the wellhead without three-phase separation.

Designed for use in oil-gas mixed wells and gas wells, especially in mid-and-late production stage, it reduces wellhead pressure, increases production, and extends life. Integrated with PLC automation and optional gas lift, the system is compact, efficient, and easy to implement.

Key Features:

No Separation Needed: Treats mixed gas, liquid, and solids directly without separation equipment, with minimal pressure loss.

Boosts Well Output: Reduces wellhead pressure to 0.1 MPa, increasing flow rate and enhancing gas production.

High Energy Efficiency: Retains up to 50% energy in comparison with conventional pumps; helps gas lifts with self-produced natural gas.

Smart & Secure Operation: Expilo-proof and PLC-regulated, enabling remote monitoring for safe, automatic operation.

Simple Installation & Expandability: Skid-mounted for easy installation; may be installed in series or parallel to meet different output demands.

Summary

As oil and gas production shifts into more remote, deeper regions, the traditional modes of transportation are often insufficient. Multiphase pumping systems offer a smarter, more efficient alternative, reducing costs, simplifying infrastructure, and enhancing flow efficiency.

Regardless of what your requirements are to facilitate recovery, minimize investment, or enhance remote operations, this technology is well worth giving serious thought to. If what you need is a trusted solution, Wingoil’s multiphase pumping system is a smart choice that you can rely on.