4 Applications of Disintegrating Frac Plug

Disintegrating frac plugs are used in oil and gas industries to block the flow of oil or gas and allow for pressure buildup in the wellbore. The plugs can be made from various materials, such as steel or rubber, and are designed to dissolve or disintegrate over time. In this article, we will discuss the various applications of disintegrating frac plugs in different industries.

Why Discuss the Applications of Disintegrating Frac Plugs?

Disintegrating frac plugs have gained popularity in recent years due to their effectiveness and efficiency in blocking the flow of oil or gas. Additionally, they are designed to dissolve or disintegrate over time, which reduces the risk of blocking the wellbore permanently. Therefore, it is essential to understand the different applications of disintegrating frac plugs in various industries to make informed decisions about their use.

4 Applications of Disintegrating Frac Plug

A. Oilfield Development

Oil Well Leak Repair

Oil well leaks can have a significant impact on production and the environment. As an important downhole drilling tool, disintegrating frac plugs can be used to repair leaks by filling the gaps and preventing the escape of oil. Compared to other repair methods, disintegrating frac plugs are more effective in sealing leaks.

Hydraulic Fracturing

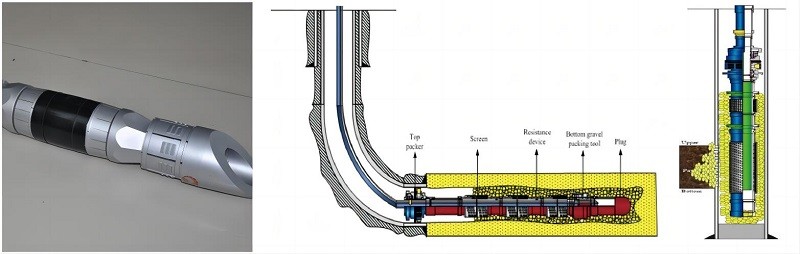

Hydraulic fracturing is the process of injecting water and chemicals into the wellbore to create fractures in the rock formations and increase oil or gas flow. Disintegrating frac plugs are used during hydraulic fracturing to block off the unwanted sections of the wellbore and allow for pressure buildup in the desired section. Compared to other methods, disintegrating frac plugs are more efficient and cost-effective.

Horizontal Wellbore Blockage

Horizontal wellbore blockages can significantly impact production and increase costs. Disintegrating frac plugs can be used to block off the affected section and allow for pressure buildup in the desired section, thereby increasing production.

B. Natural Gas Extraction

Coalbed Methane Well Leak Repair

Coalbed methane wells are prone to leaks due to the high pressure and complex geological formations. Disintegrating frac plugs can be used to repair leaks by filling the gaps and preventing the escape of gas. Compared to other repair methods, disintegrating frac plugs are more effective in sealing leaks.

Natural Gas Pipeline Repair

Natural gas pipelines are prone to leaks and corrosion due to their age and exposure to the elements. Disintegrating frac plugs can be used to seal the leaks and prevent the escape of gas, thereby reducing the risk of accidents and increasing safety.

C. Water Resource Engineering

Dam Spillway Repair

Dam spillways are crucial for controlling the water flow and preventing flooding. Disintegrating frac plugs can be used to repair spillways by blocking off the damaged section and allowing for pressure buildup in the desired section, thereby increasing the effectiveness of the spillway.

Canal Leakage Repair

Canal leakage can significantly impact the water supply and increase costs. Disintegrating frac plugs can be used to repair leaks by filling the gaps and preventing the escape of water. Compared to other repair methods, disintegrating frac plugs are more effective in sealing the leaks.

D. Other Applications

Wind Turbine Tower Maintenance

Wind turbine towers are prone to corrosion and wear and tear due to their exposure to the elements. Disintegrating frac plugs can be used to seal the cracks and prevent further damage, thereby increasing the lifespan of the tower.

Coal Mine Workface Blockage

Coal mine workface blockages can significantly impact production and increase costs. Disintegrating frac plugs can be used to block off the affected section and allow for pressure buildup in the desired section, thereby increasing production.

In the above-mentioned application scenarios, the disintegrating frac plug plays an important role. For example, when plugging oil wells, the Disintegrating frac plug can prevent oil leakage by filling the gaps. Compared with other repair methods, the disintegrating frac plug has a better sealing effect. Similarly, the disintegrating frac plug is also widely used in the repair of natural gas pipelines. It can be used to seal leaks or cracks in pipelines, effectively preventing natural gas leakage and other safety issues. In addition, the disintegrating frac plug can also be used to solve problems such as repairing spillways of dams and blocking leaks in water gates in water conservancy projects, as well as sealing and maintaining wind turbine towers and coal mining faces.

In conclusion, although the disintegrating frac plug is only one of the downhole tools, it has a wide range of applications and can be used in various fields and industries. In the future, with the continuous development and improvement of technology, the application scope of the disintegrating frac plug will continue to expand, providing more comprehensive and effective sealing solutions for various industries.