5 Basic Information About Hydraulic Power Units

Hydraulic power units are used as oil supply units and are optimized for a variety of applications, such as truck operation in harsh environments, heavy lifting for extended periods, and other applications where high-performance and high-quality products are required.

What is a hydraulic power unit?

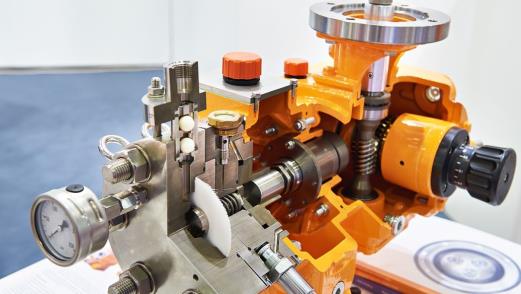

The hydraulic power unit is used as an oil supply device, which can be filled with water, oil, or special media. It is a complete hydraulic unit and only needs to connect the various components. The hydraulic system can be used for various pressure testing equipment, and can also provide a stable hydraulic power source for hydraulic fixtures. It is connected with several hydraulic cylinders through an external pipeline system to control the actions of multiple groups of valves. The oil tank, oil pump, and accumulator form an independent closed power oil source system.

How does the hydraulic power unit work?

Control elements such as hydraulic servo valves are directly installed on the hydraulic cylinder, and high-pressure oil is forced into the cylinder through this valve, or high-pressure oil is discharged from it. Under normal conditions, the oil pump supplies oil to the system, automatically maintains the rated pressure of the system, and realizes the function of maintaining the valve at any position by locking the control valve; in the working state, the hydraulic actuator is controlled by the solenoid valve, and the system command signal Activate the solenoid valve, control the oil pressure and the energy release of the accumulator, and then control the oil cylinder slide valve, drive the valve through the mechanical transmission mechanism, and implement rapid closing, normal opening and closing and test control.

The high-pressure oil cylinder can be fixed on the valve stem or directly used as an actuator. The excess hydraulic oil is returned to the hydraulic oil station so that the pipeline system can control several valves connected in parallel with one oil inlet pipe and one oil return pipe. This hydraulic station with special drive technology is used to control the actuator action of the main steam valve and the steam turbine bypass system.

Typically, a pump needs to be driven by compressed air to generate pressure. That is, the pump can be connected to the existing compressed air piping system on-site and can generate pressure without connecting to a power source.

Assembly of the hydraulic power unit

The structural size of the pump and the flow ratio required for operation determine the difference in the limiting results of the power unit. For simple commissioning and applications without special requirements, the power pack will be equipped with all standard originals. There is an air control unit including a combined filter and water separator, pressure regulator, pressure gauge, and manual shut-off valve.

In all applications in the field of oil hydraulics, the pump can be installed in the oil tank, which makes the structure compact and saves space. As standard, water- or chemical-filled pump-mounted fuel tanks range from 6.5L to 70L. A larger capacity fuel tank is also available as required.

In the high-pressure part, when the hydraulic power unit is connected to the test piece, it can be equipped with a pressure relief valve (expansion valve) and a manifold with one or more pressure outlets (which can be closed individually or all at the same time).

Advantages of hydraulic power units

• The pump stops automatically when the set final pressure is reached

• No energy consumption for long-term pressure maintenance

• The medium will not overheat during pressure holding

• Automatic depressurization by pump

• Control operating pressure by adjusting drive air pressure

• Simple installation, reliable operation, and easy maintenance

Application of Hydraulic Power Unit

Portable hydraulic power packs can be used wherever hydraulic pressure is required. Widely used in steel construction, boiler construction, and construction of fuel tanks and reactors, as well as in mines, smelters, machine building, and tong factories. Over the years, they have proven their high performance during inspection and acceptance as well as in hydraulic clamping systems.

The power unit also provides the drive for hydraulic presses and punching systems, which can be used in aircraft lifting, large equipment fixtures, pressure vessels, and pressure piping systems.

In addition, the system will be used for hydraulic clamps and other equipment that need to maintain pressure for a long time, such as tire curing presses and clamp overload protection. For this purpose, the hydraulic unit can be provided with a circuit arrangement into the gripper on one or both sides. The direct return of compressed air enables the connection of a fast circuit.

The hydraulic unit is compact, easy to operate, and robust to pressure. The hydraulic power station is not easily damaged in high humidity, dust, and high-temperature conditions. Since no power supply is required, the hydraulic power pack can be used in explosion-proof locations.

About WINGOIL

WINGOIL is a professional manufacturer of high-pressure equipment and flows control solutions provider for the oil and gas industry. We design hydraulic power equipment according to your requirements. Sales engineers as well as technical engineers are happy to provide you with professional advice and will advise you on the selection of hydraulic power equipment that is right for you.