Basic knowledge of quick couplings

Devices called quick couplings are added to the outside of the work equipment on numerous types of earth-moving and construction machinery. They facilitate the fast replacement of operating tools or buckets.

What is the quick coupling

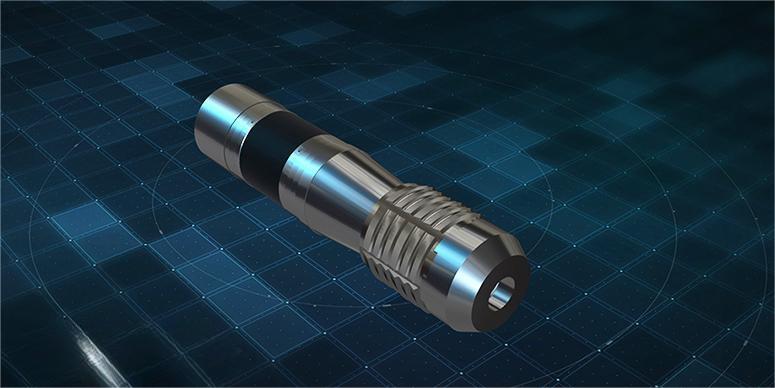

Quick-connect couplings are connectors or fittings used to mate fluid lines with equipment that requires repeated connections and disconnections. Their design is simple: a male end—or plug—is inserted into a female end—or socket—to make a secure, leak-tight seal. They are sometimes referred to as “push-to-connect” because all that is needed to link them is a brief push.

Common metals selection for quick couplings

The fluids being transferred through the system are often taken into account while choosing the materials for quick couplers. Cost, adaptability, environmental circumstances, and necessary pressure ratings are further decision criteria.

Aluminum: lightweight and resistant to corrosion. Plumbing frequently makes use of metal, and aluminum tubing’s preferred fitting material is aluminum. Aluminum is utilized when great corrosion resistance is required despite having poor tensile strength on its own. To increase its tensile strength and hardness, it is alloyed with zinc, copper, silicon, manganese, and/or other metals.

Brass: sturdy, long-lasting, corrosion-resistant material that is ductile at high temperatures and has good conductivity. Brass, a copper and zinc alloy, is a frequently used quick coupler material due to its outstanding performance characteristics and machinability. Different protective or ornamental treatments for brass fittings are available, and they should match the finish of the tubing.

Cast iron: Strong and extremely abrasion resistant. Due to its resistance to abrasive materials like sand, gravel, solid wastes, and debris, cast iron fittings and tubes are largely employed in the construction of buildings for sanitary, storm drain, waste, and vent tubing applications.

Copper has good conductivity and is particularly resistant to corrosion. Copper fittings are crucial for numerous plumbing and heating applications and are frequently used in water supply lines for homes. Usually used in connection with copper tubing, copper fittings can be either flexible or rigid. The only type of copper suited for flare connections is soft or ductile copper, which is easily twisted and manipulated. Since rigid copper cannot be bent, directed fittings are needed to navigate around curves and other obstructions.

Steel is a strong, long-lasting material that is highly heat resistant. Steel is an iron and carbon alloy that is frequently alloyed with other metals to increase its durability and corrosion resistance. It is utilized in commercial and industrial settings to transport fluids like water and dangerous gases. Zinc is applied to galvanized steel to prevent rust and chemical corrosion. Higher carbon content is alloyed into carbon steel to boost its strength and endurance.

Stainless steel has good chemical and corrosion resistance and is relatively robust. A steel alloy having more than 10.5% chromium is known as stainless steel, which offers exceptional corrosion resistance for hygienic applications and those involving corrosive fluids and materials. It is a typical option for rapid coupler material.

Types of quick couplings

Ball and sleeve connections employ a “ball” or male end which fits into a female outer sleeve. To join and separate the coupler’s halves, the user can retract the sleeve by pulling it back.

Cam-lock fittings are connected using tabs on the female half which fold down to lock the receiver in place after it is inserted. Hose connections to tanks or other hoses may be made quickly and securely using these connectors. They are employed in numerous heavy-duty hose applications, including sludge/sewage pumping and fire hose.

Luer locks are sleeve fittings that afford simple, effective connections via a quick twisting action. They are typically designed for brief, singular usage. They are most frequently utilized in laboratory and medical applications.

Push-to-connect fittings have ends that are made to connect by simply pushing one end into another. They function similarly to ball and sleeve connections and are occasionally used interchangeably. They separate via a straightforward collar retraction technique.

Twist or bayonet fittings use a twist action to engage and release the connection (1/8 to 1/4 of a turn).

Application of quick couplings

In some cases, quick couplers are graded and developed expressly for a given application or sector.

Chemical fitting – Quick couplers for specific chemicals, such as gasoline, oil, solvents, acids, bases, etc., may be constructed.

Gas fitting – Gas quick couplers are specifically designed for explosive and noxious gases such as propane and phosgene.

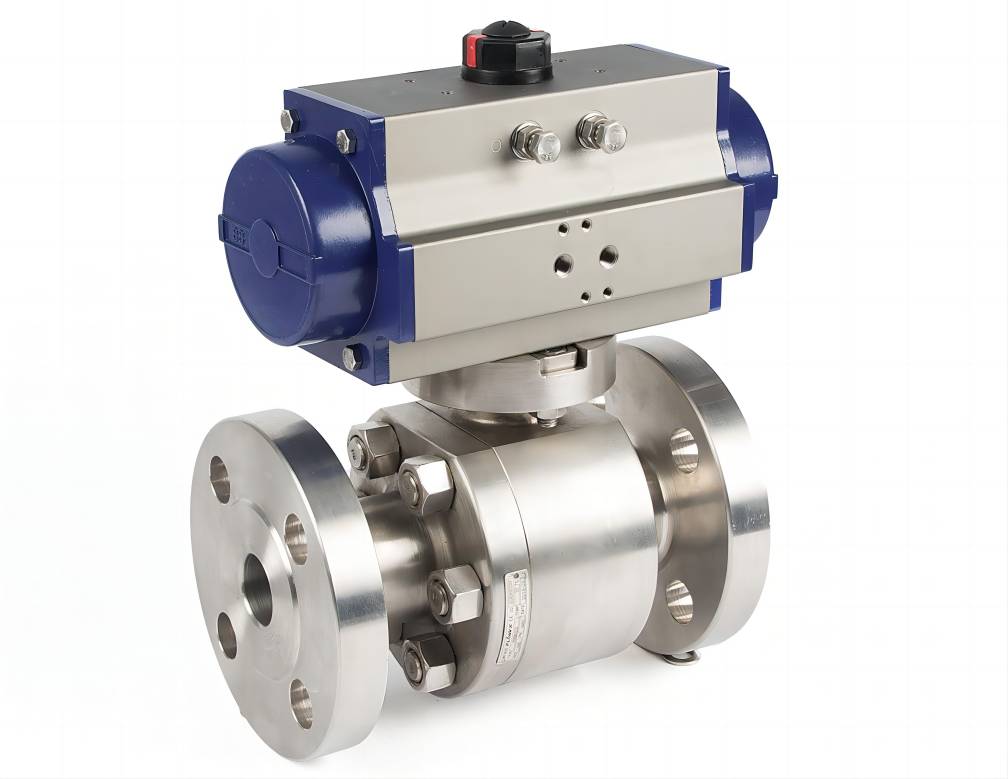

Hydraulic fitting – Hydraulic fast couplers are made specifically for hydraulic lines and are rated for them. High-pressure ratings are particularly important for these fast couplers.

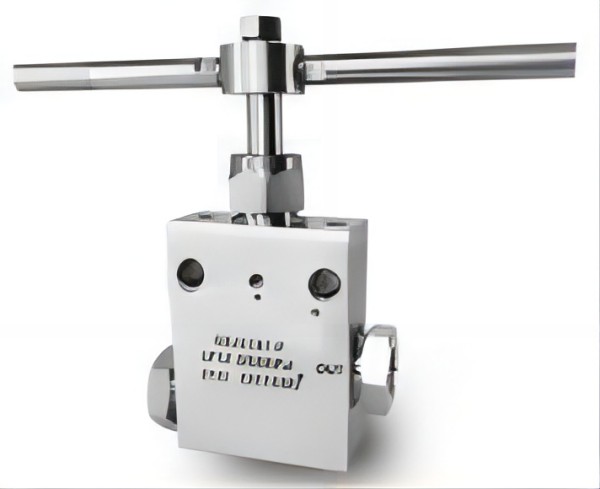

Pneumatic fitting – For usage in compressed air lines and pneumatic systems, pneumatic fast couplers were created specifically.

Sanitary/food-grade fitting – Sanitary and food-grade quick couplers are made with sanitary uses in mind, such as the food, beverage, pharmaceutical, and medical sectors.

Water fitting – Water fast couplers are approved for use with pressured, potable water for commercial, municipal, and residential applications.

Summary

Quick couplings were discussed in this article in terms of their definition, varieties, constructions, and uses. A fast coupler can be a practical option for you if any of your equipment has a liquid line, gas line, or hydraulic line.