Micro metering needle valves: Precision Flow Control in Oilfield Equipment

Micro metering needle valves are crucial components in oilfield equipment, providing precise control and regulation of fluid flow. In this article, we will explore the functions, applications, advantages, considerations, and significance of these valves in the oil and gas industry.

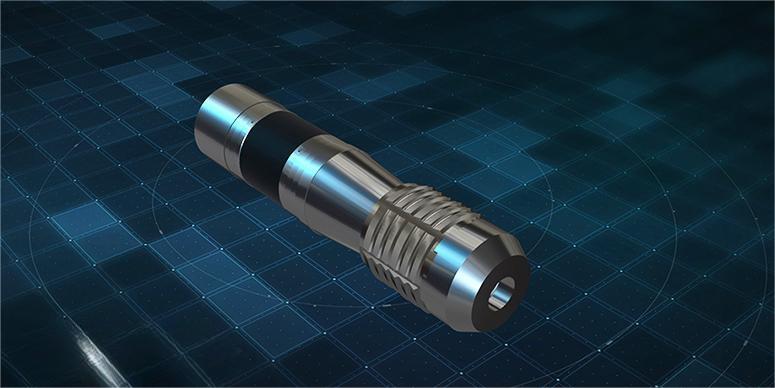

Purpose and Function of Micro metering needle valves

Micro metering needle valves serve several important functions in oilfield equipment:

- Controlling Fluid Flow

These valves play a critical role in regulating the flow of fluids within oilfield equipment, enabling operators to have precise control over the rate of flow.

- Precision Metering and Regulation

Micro metering needle valves offer the ability to precisely meter and regulate fluid flow, ensuring that desired flow rates are achieved accurately, even in demanding operating conditions.

- Fine Adjustment of Flow Rates

These valves excel at fine-tuning flow rates, making them ideal for applications where precise control is essential, such as in metering and sampling systems.

- Preventing Excessive Pressure Drops

Micro metering needle valves provide a controlled and gradual reduction of fluid flow, helping to prevent excessive pressure drops that could potentially damage the system.

Applications of Micro metering needle valves in Oilfield Equipment

Micro metering needle valves find extensive applications in various oilfield equipment, including:

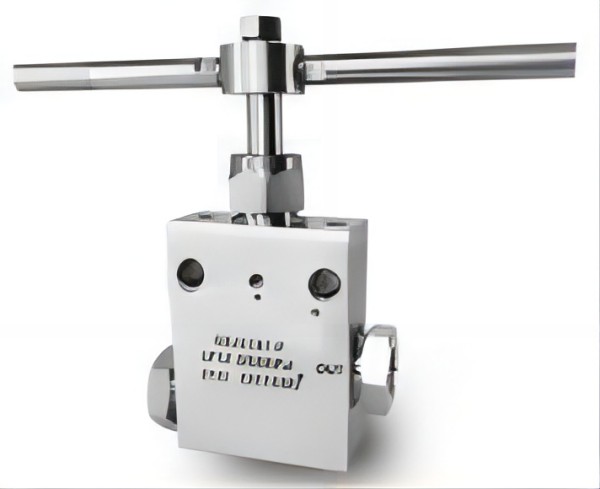

- Wellhead Equipment

Choke Valves: Micro metering needle valves are commonly used as choke valves in wellheads to regulate the flow of oil or gas, allowing for optimal production rates while maintaining pressure control.

Pressure Control Equipment: These valves are employed in pressure control systems to precisely adjust and stabilize the pressure within the wellhead.

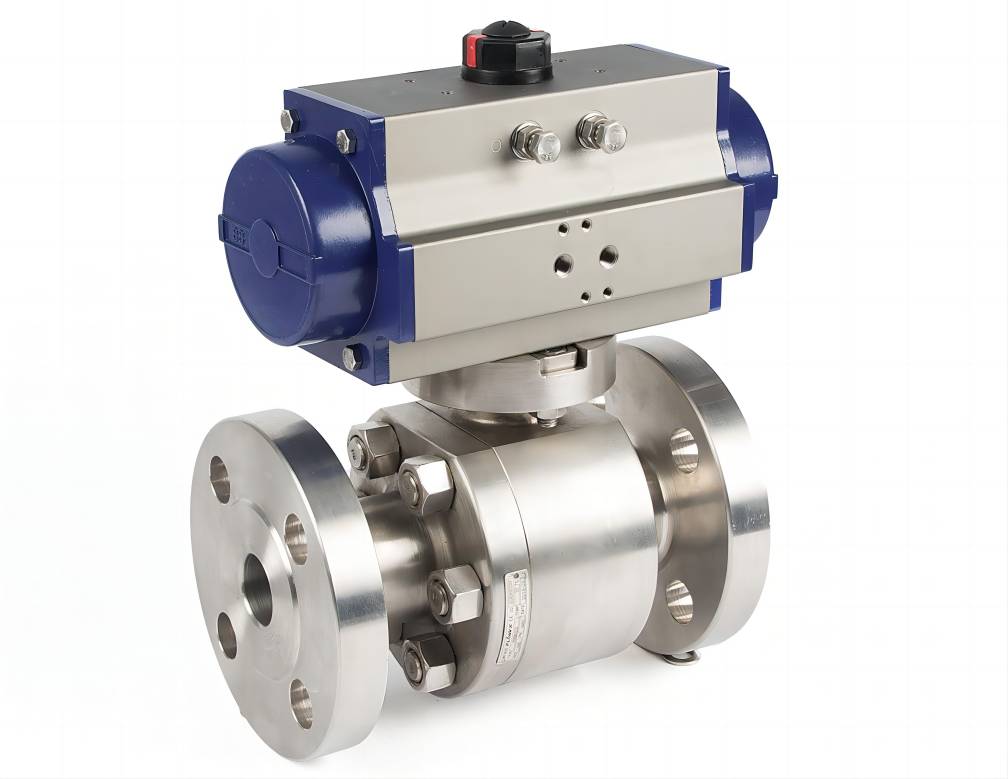

- Hydraulic Systems

Control Valves: Micro metering needle valves regulate the flow of hydraulic fluid in hydraulic systems, controlling the movement and operation of components such as actuators and cylinders.

Flow Control Devices: These valves serve as flow control devices, ensuring precise flow rates in critical processes within hydraulic systems.

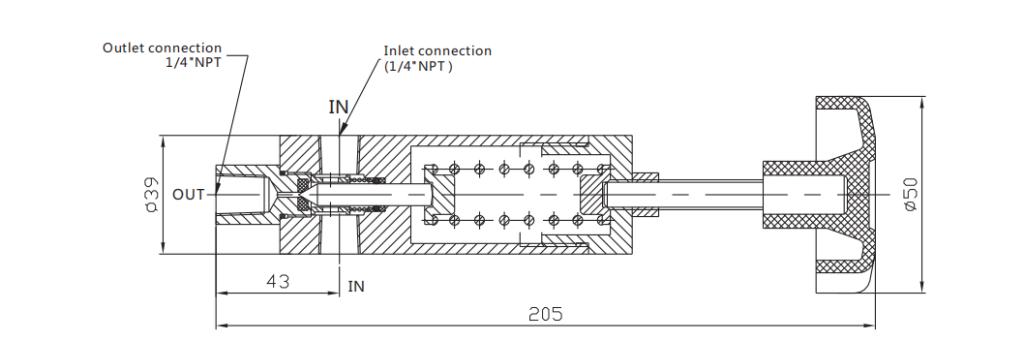

- Metering and Sampling Systems

Proportional Control Valves: Micro metering needle valves play a crucial role in proportional control systems, providing accurate and proportional control of fluid flow for applications such as blending, dosing, or batching.

Precision Fluid Measurement: These valves enable precision fluid measurement in metering and sampling systems, ensuring accurate measurements for analysis and monitoring purposes。

Advantages and Benefits of Micro metering needle valves

Micro metering needle valves offer several advantages that contribute to improved performance and efficiency in oilfield equipment:

- Precise Flow Control

These valves provide unparalleled precision in controlling flow rates, allowing for accurate and consistent flow control in critical oilfield operations.

- High Accuracy and Repeatability

Micro metering needle valves exhibit high accuracy and repeatability, ensuring consistent performance over extended periods. This characteristic is essential for maintaining operational efficiency and meeting stringent industry requirements.

- Compact Size and Lightweight

With their compact size and lightweight design, these valves can be easily integrated into space-constrained oilfield equipment without compromising functionality or performance.

- Resistance to Harsh Operating Conditions

Micro metering needle valves are specifically designed to withstand the harsh operating conditions often encountered in the oilfield environment. They can withstand high pressures, extreme temperatures, corrosive substances, and abrasive fluids.

- Improved System Performance and Efficiency

By providing precise flow control and regulation, Micro metering needle valves optimize system performance, enhance process efficiency, and minimize waste. Their ability to deliver accurate flow rates ensures that resources are utilized effectively, leading to improved productivity and cost-effectiveness.

Considerations and Selection Criteria for Micro metering needle valves

When selecting Micro metering needle valves for oilfield equipment, it is important to consider the following factors:

- Flow Rate Requirements: Determine the desired flow range and ensure that the valve’s specifications align with the application’s flow rate requirements.

- Pressure and Temperature Ratings: Consider the operating pressure and temperature conditions to ensure that the valve can handle the specific demands of the oilfield equipment.

- Material Compatibility: Evaluate the compatibility of valve materials with the fluids being handled, considering factors such as corrosion resistance, chemical compatibility, and erosion resistance.

- Environmental Conditions: Assess the environmental conditions, including potential exposure to extreme weather, harsh chemicals, or abrasive particles. Select valves that are built to withstand such conditions.

- Installation and Maintenance Requirements: Consider ease of installation, maintenance, and accessibility for troubleshooting or repairs. Opt for valves that are designed for easy integration and servicing.

Conclusion

Micro metering needle valves play a critical role in oilfield equipment by providing precise flow control, metering, and regulation. Their applications range from wellhead equipment and hydraulic systems to metering and sampling systems. The advantages of these valves include precise flow control, high accuracy, compact size, resistance to harsh conditions, and improved system performance and efficiency.

With ongoing advancements in valve technology and the integration of digital control systems, the future holds even more potential for Micro metering needle valves to further revolutionize oilfield equipment. These valves will continue to play a vital role in meeting the industry’s demand for precise flow control and metering, driving advancements, and enabling new applications in the ever-evolving oil and gas sector.