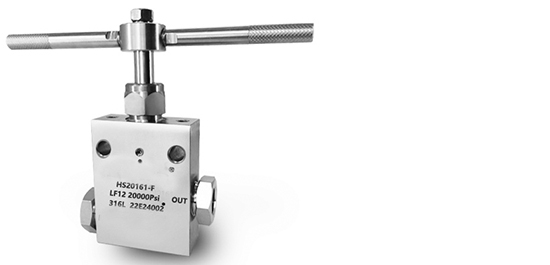

Micro Metering Needle Valves

- Maximum working pressure: 60,000 psi (4140 bar)

- Wingoil Micro Metering Needle Valves are suitable for small flow applications with more accurate control.

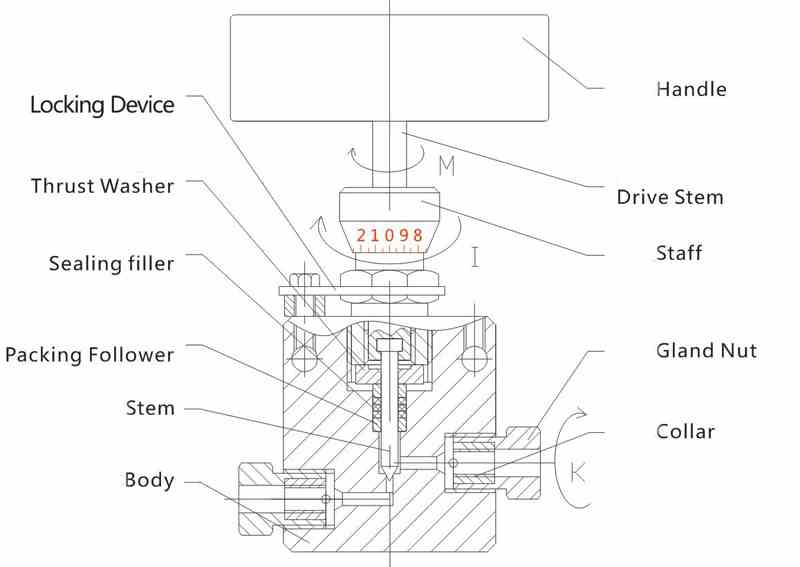

- The valve needle with a special angle design acts on the precisely matched replaceable valve seat to form throttling, with a wide flow adjustment range and smooth differential pressure change.

- These valves are only used for metering and cannot be closed absolutely.

- The minimum flow is factory set and acts at “0”.

- Do not operate the valve below zero, otherwise, it will cause damage.

- When the closing operation is required, the valves of the Wingoil series shall be installed in series with the precision metering valve.

Share to

Features

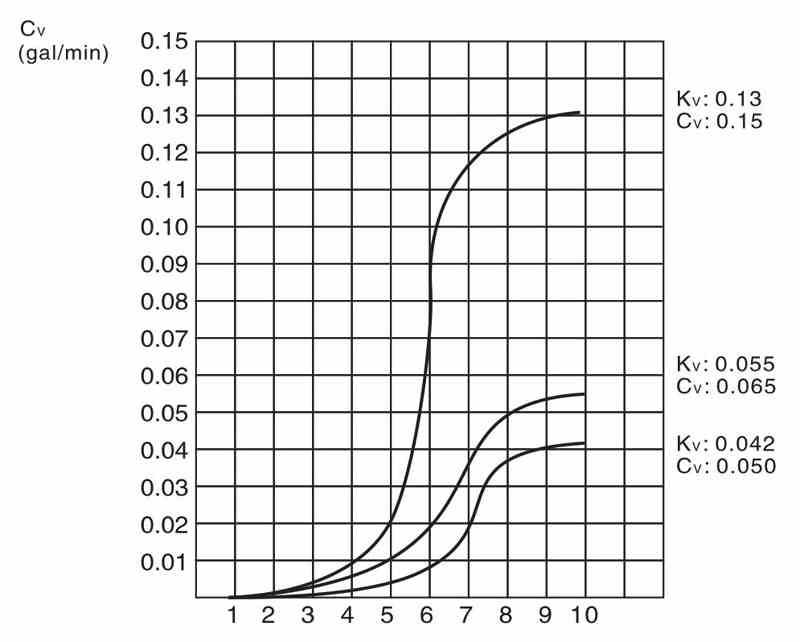

- Perfect flow curve

- Larger adjustment stroke

- Valve needle with a special angle design

- Structure optimization of the valve body

Characteristics

- All needle valves record the reliability of the serial number and provide complete traceability of all pressure-retaining parts.

- Wingoil needle valve provides maximum safety and reliability. Even under adverse operating conditions, the valve can be installed in any direction and can effectively seal gas and liquid media.

- The valve needle and valve stem are non-rotating. Therefore, the service life and reliability of the valve are increased. Pressure parts are made of high-quality corrosion-resistant stainless steel.

Applicable Industries

- The flow of various types of fluids such as mud, oil, liquid metal, and radioactive media

- Ultra-high pressure system can be used to control air, water, steam, and various corrosive media

- University scientific research, monitoring station, superhard material manufacturing, isostatic pressure treatment

- High-pressure water cleaning, oil field and gas field, chemical industry and petrochemical industry, research, and development

- Ultra-high static pressure extrusion, powder metallurgy, metal forming, geophysical, geological and physical research, and other fields

| Valve Pattern |

Catalog Number |

O.D. Tube |

Orifice (mm) |

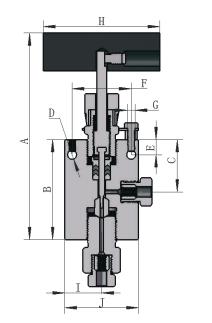

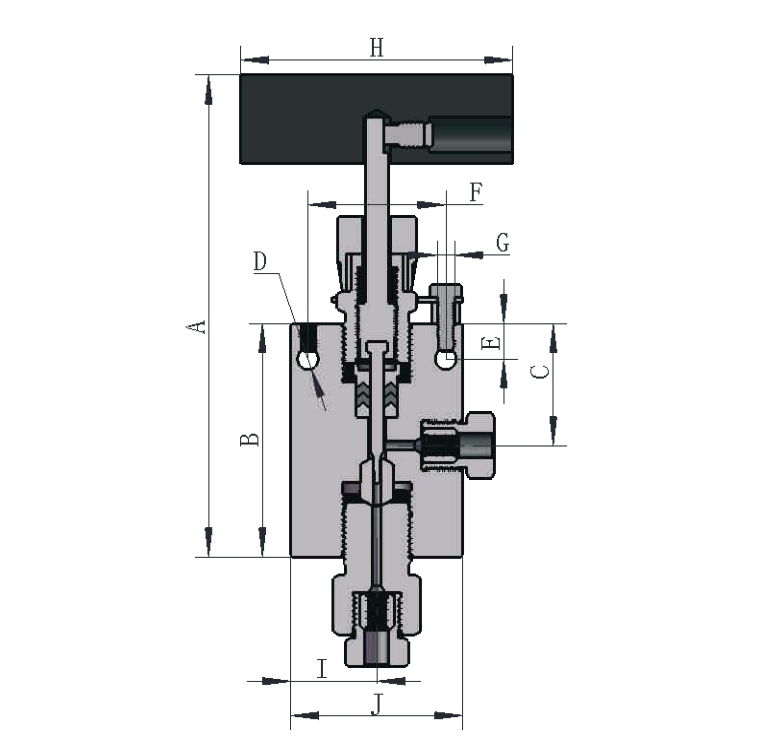

Dimensions (mm) |

Valve Panel Hole |

Block Thick ness |

||||||||||

| A | B | C | D | E | F | G | H | I | J | K | ||||||

|

HS10116-K-F | 1/8″ | 1.57 | 136.5 | 66.5 | 34.5 | 6 | 10 | 40 | M5 | 79 | 25 | 50 | / | 24 | 24 |

| Hs30126- F | 1/4″ | 1.57 | 136.5 | 66.5 | 34.5 | 6 | 10 | 40 | M5 | 79 | 25 | 50 | / | 24 | 24 | |

| HS30136-F | 3/8″ | 1.57 | 137 | 66 | 34.5 | 6 | 10 | 40 | M5 | 79 | 25 | 50 | / | 24 | 30 | |

| HS60126-F | 1/4″ | 1.57 | 136.5 | 66.5 | 34.5 | 6 | 10 | 40 | M5 | 79 | 25 | 50 | / | 24 | 26 | |

| HS60136-F | 3/8″ | 1.57 | 137 | 66 | 34.5 | 6 | 10 | 40 | M5 | 79 | 25 | 50 | / | 24 | 30 | |

| Catalog Number | O.D.Tube | Orifice | Dimensions(mm) | Valve Panel Hole | Block Thick-ness | ||||||||||

| A | B | C | D | E | F | G | H | I | J | K | |||||

| HS10116-K-F | 1/8” | 1.57mm | 136.5 | 66.5 | 34.5 | 6 | 10 | 40 | M5 | 79 | 25 | 50 | / | 24 | 24 |

| HS10116-F | 1/4” | 1.57mm | 136.5 | 66.5 | 34.5 | 6 | 10 | 40 | M5 | 79 | 25 | 50 | / | 24 | 24 |

| HS10116-F | 3/8” | 1.57mm | 137 | 66 | 34.5 | 6 | 10 | 40 | M5 | 79 | 30 | 60 | / | 24 | 30 |

| HS10116-F | 1/4” | 1.57mm | 136.5 | 66.5 | 34.5 | 6 | 10 | 40 | M5 | 79 | 25 | 50 | / | 24 | 26 |

| HS10116-F | 3/8” | 1.57mm | 137 | 66 | 34.5 | 6 | 10 | 40 | M5 | 79 | 30 | 60 | / | 24 | 30 |

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————