Basic Pneumatic Driven Needle Valves

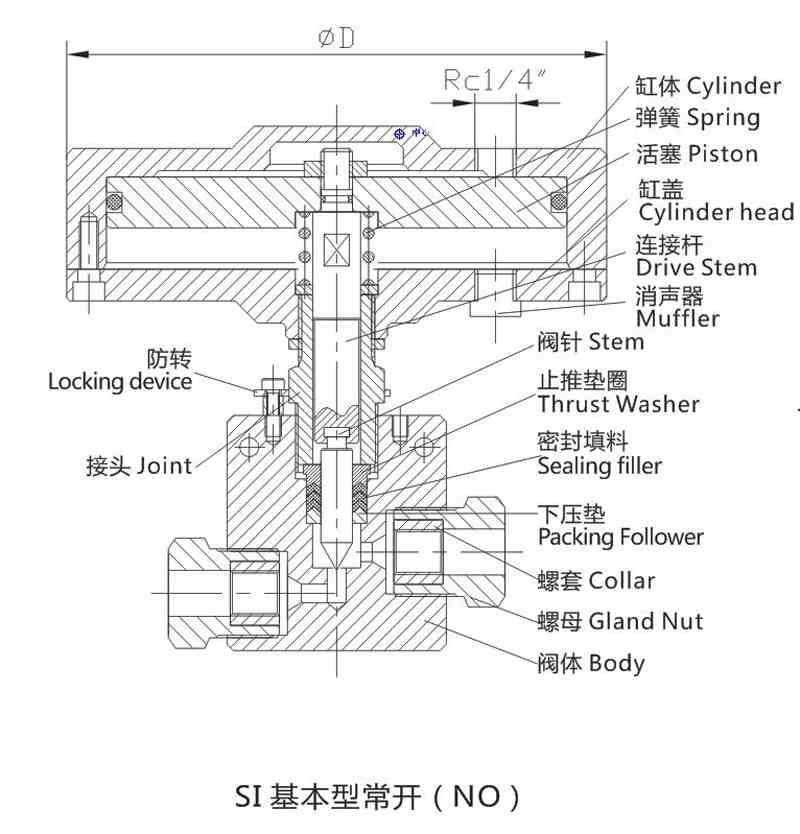

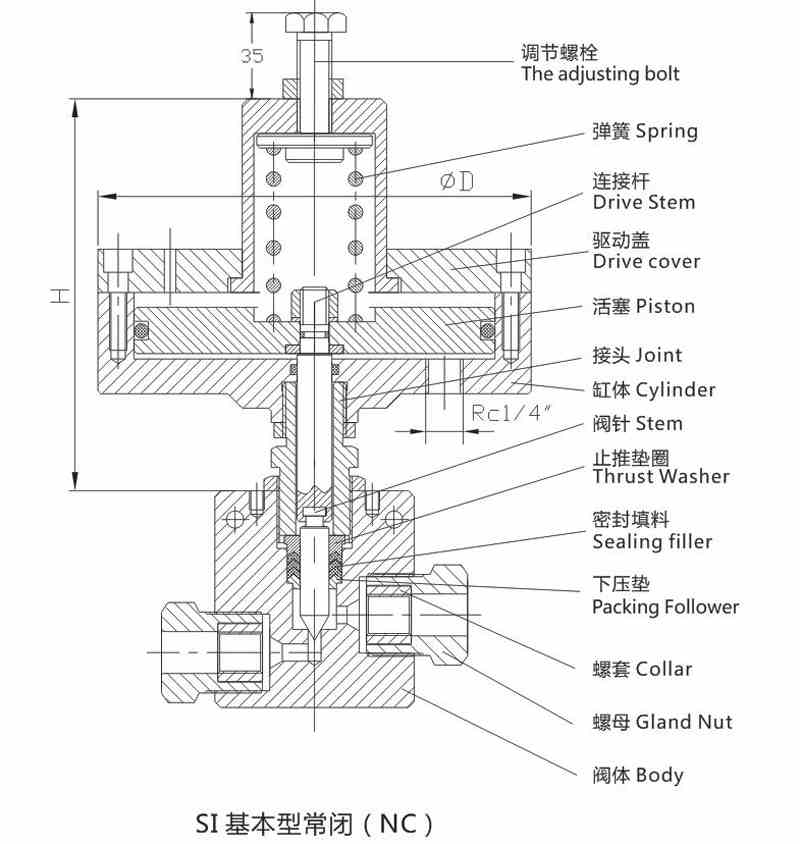

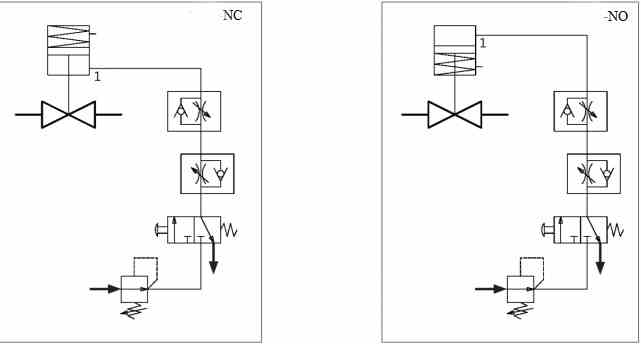

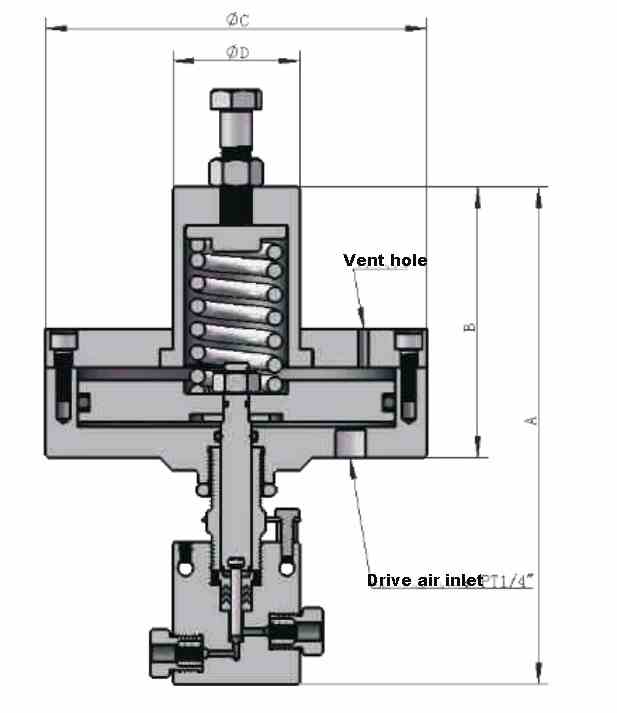

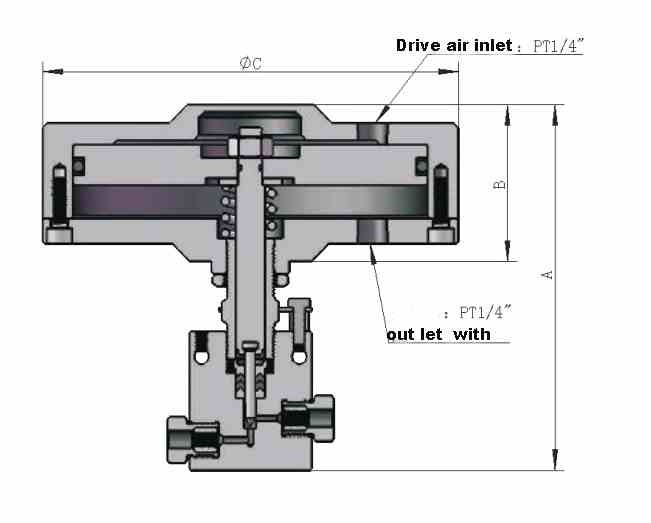

- Wingoil pneumatic control valve series uses low pressure compressed air (75psi) as the power to push the cylinder to control the on-off of ultra-high pressure fluid in the valve body, which has two forms: normally open and normally closed. There are 6 types of valve body connection port positions, which meet various connection requirements.

Share to

Overview

The needle valve provides maximum safety and reliability. Even under adverse operating conditions, the valve can be installed in any direction and can effectively seal gas and liquid media. The maximum working pressure can reach: 60,000 psi (4140 bar). Products with switch position sensing can be provided: HI type, convenient for remote control.

The valve body is made of 316 material, and the pressure bearing parts are made of high-quality corrosion-resistant stainless steel. The hard sealing valve needle matched with the valve port is made of 17-4PH or hard alloy. The valve needle and valve stem are non-rotating design, wear-resistant, long life, and meet various working conditions. All needle valves record the reliability of the serial number. Provide complete traceability of all pressure retaining parts.

SI-type Pneumatic Driven Needle Valves Features

- The spring returns the air to open or close.

- Suitable for high-pressure gas and liquid control system or test system.

- Piston-type pneumatic valves offer unique and reliable designs that are longer than diaphragm valves.

| Actuator max. allowable working pressure | 7 bar / 100 psi |

| Allowable piston temperature range | -29°C to 93°C (-20°F to 200°F) |

| Max. working pressure | 4140 bar / 60,000 psi |

| Working medium | Gas, oil and water |

| Standard operating temperature | -30℃ to 150℃ (-22°F to 302°F) |

| Pressure | Tube-Ø | Orifice | 2-Way Staraight | 2-Way Angel | 3-Way 2 | 3-Way 1 | 3-Way ,2-Stem Manfoldon pressure | 2-Way Angel/Replaceable- |

| on pressure | on pressure | seat | ||||||

| Kpsi | 1/4” | 2.8mm | SI20121-NC/NO | SI20122-NC/NO | SI20123-NC/NO | SI20124-NC/NO | SI20125-NC/NO | SI20126-NC/NO |

| 3/8” | 4.5mm | SI20131-NC/NO | SI20132-NC/NO | SI20133-NC/NO | SI20134-NC/NO | SI20135-NC/NO | SI20136-NC/NO | |

| 9/16” | 7mm | SI20141-NC/NO | SI20142-NC/NO | SI20143-NC/NO | SI20144-NC/NO | SI20145-NC/NO | SI20146-NC/NO | |

| 30Kpsi | 1/8” | 1.2mm | SI30111-NC/NO | SI30112-NC/NO | SI30113-NC/NO | SI30114-NC/NO | SI30115-NC/NO | SI30116-NC/NO |

| 1/4” | 2.4mm | SI30121-NC/NO | SI30122-NC/NO | SI30123-NC/NO | SI30124-NC/NO | SI30125-NC/NO | SI30126-NC/NO | |

| 3/8” | 3.2mm | SI30131-NC/NO | SI30132-NC/NO | SI30133-NC/NO | SI30134-NC/NO | SI30135-NC/NO | SI30136-NC/NO | |

| 9/16” | 3.5mm | SI30141-NC/NO | SI30142-NC/NO | SI30143-NC/NO | SI30144-NC/NO | SI30145-NC/NO | SI30146-NC/NO | |

| 60Kpsi | 1/4” | 2mm | SI60121-NC/NO | SI60122-NC/NO | SI60123-NC/NO | SI60124-NC/NO | SI60125-NC/NO | SI60126-NC/NO |

| 3/8” | 2mm | SI60131-NC/NO | SI60132-NC/NO | SI60133-NC/NO | SI60134-NC/NO | SI60135-NC/NO | SI60136-NC/NO | |

| 9/16” | 3mm | SI60141-NC/NO | SI60142-NC/NO | SI60143-NC/NO | SI60144-NC/NO | SI60145-NC/NO | SI60146-NC/NO |

| Control type | Working pressure | Common code | Outer diameter of connecting pipe | Valve type | Valve category | Link type | Valve application |

| SI Pneumatic needle valve | 06 6000psi | 1 | 1 1/8″O.D. | 1 direct connection | NC normal close | No standard connection | H High-temperature valve |

| 10 10000psi | 1 | 2 1/4″O.D. | 2 right angle | NO normally open | T NPT | L Low temperature | |

| 20 20000psi | 1 | 3 3/8″O.D. | 3 Tee (one in and two out) | F Precision throttle valve | R G、BSPP | H₂ | |

| 30 30000psi | 1 | 4 9/16″O.D. | 4 Tee (one in and two out) | H high temperature | C Rc、RT、ZG | ||

| 60 60000psi | 1 | 6 3/4″O.D. | 5 Three-way two-control valve | L Low temperature | K Single ferrule | ||

| 8 1″O.D. | 6 Replaceable valve seat | K Ferrule valve |

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————