Burst Pressure Testing Machine for Wellhead Pressure Test in the Gas and Oil Industry

A burst pressure testing machine is a device used to test the pressure capacity of a material or component before it fails. It is an essential safety tool in the gas and oil industry, where equipment is subjected to extreme pressures. Burst pressure testing is used to test the integrity of wellhead equipment, pipelines, pressure vessels, and other equipment used to transport and store gas and oil.

There are three main types of burst pressure testing machines: hydraulic, pneumatic, and combined hydraulic/pneumatic.

- Hydraulic burst pressure testing machines use hydraulic fluid to apply pressure to the test specimen. These machines are typically more accurate than pneumatic burst pressure testing machines, but they can also be more expensive.

- Pneumatic burst pressure testing machines use compressed air to apply pressure to the test specimen. These machines are less expensive than hydraulic burst pressure testing machines, but they may not be as accurate.

- Combined hydraulic/pneumatic burst pressure testing machines use a combination of hydraulic fluid and compressed air to apply pressure to the test specimen. These machines offer the best of both worlds, but they are also the most expensive type of burst pressure testing machine.

Working Principle of a Burst Pressure Testing Machine

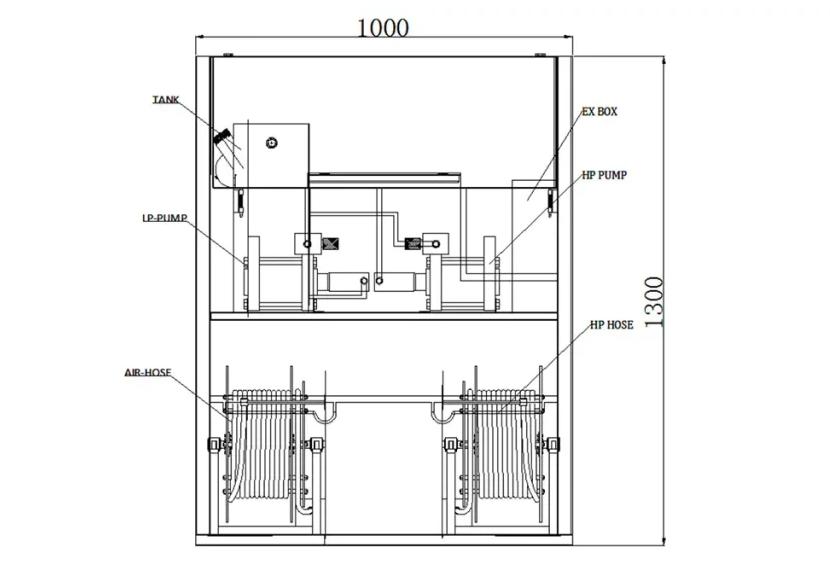

A burst pressure testing machine typically consists of a pressure source, test chamber, test specimen, pressure measurement system, and safety features.

- The pressure source provides the pressure that is applied to the test specimen. This can be a hydraulic pump, air compressor, or other type of pressure source.

- The test chamber is a sealed vessel in which the test specimen is placed. The test chamber must be strong enough to withstand the pressures that will be applied to the test specimen.

- The test specimen is the material or component that is being tested. It can be a section of pipe, a pressure vessel, or any other type of component.

- The pressure measurement system measures the pressure that is applied to the test specimen. This information is used to determine the burst pressure of the test specimen.

- The safety features are designed to protect the operator and prevent damage to the equipment in the event of a failure. These safety features may include pressure relief valves, rupture discs, and emergency stop switches.

Applications of Burst Pressure Testing in the Gas and Oil Industry

Burst pressure testing is used in a variety of applications in the gas and oil industry, including:

- Testing the integrity of wellhead equipment: The wellhead is the point at which the well meets the surface. It is important to ensure that the wellhead equipment is strong enough to withstand the pressures of the well. Burst pressure testing is used to test the integrity of wellhead valves, connectors, and other equipment.

- Testing the strength of materials used in the construction of gas and oil wells: The materials used to construct gas and oil wells must be able to withstand the extreme pressures and temperatures that they will be subjected to. Burst pressure testing is used to test the strength of these materials, such as casing, tubing, and cement.

- Testing the integrity of pipelines and pressure vessels: Pipelines and pressure vessels are used to transport and store gas and oil. It is important to ensure that these pipelines and pressure vessels are strong enough to withstand the pressures of the gas and oil. Burst pressure testing is used to test the integrity of these pipelines and pressure vessels.

- Commissioning new pipelines and pressure vessels: When new pipelines and pressure vessels are installed, they must be commissioned to ensure that they are safe and reliable. Burst pressure testing is one of the tests that are performed during the commissioning process.

- Recertifying existing pipelines and pressure vessels: Existing pipelines and pressure vessels must be recertified at regular intervals to ensure that they are still safe and reliable. Burst pressure testing is one of the tests that are performed during the recertification process.

Benefits of Using a Burst Pressure Testing Machine

There are many benefits to using a burst pressure testing machine, including:

- Improved safety and reliability of gas and oil operations: Burst pressure testing helps to identify and eliminate weaknesses in gas and oil equipment before they can cause accidents.

- Reduced risk of accidents and environmental damage: Burst pressure testing helps to reduce the risk of accidents and environmental damage that can occur if gas and oil equipment fails.

- Extended service life of gas and oil equipment: Burst pressure testing helps to extend the service life of gas and oil equipment by identifying and eliminating weaknesses before they can cause premature failure.

- Compliance with industry standards and regulations: Burst pressure testing is required by many industry standards and regulations. Using a burst pressure testing machine helps to ensure compliance with these standards and regulations.

Conclusion

Burst pressure testing machines are an essential safety tool in the gas and oil industry. Burst pressure testing helps to ensure the integrity of wellhead equipment, pipelines, pressure vessels, and other equipment used to transport and store gas and oil. Burst pressure testing can help to improve the safety and reliability of gas and oil operations, reduce the risk of accidents and environmental damage, extend the service life of gas and oil equipment, and ensure compliance with industry standards and regulations.