How To use Hydrostatic Test Pump and Complete a Hydrostatic Test?

The Hydrostatic Test Pump generates calibration pressures of up to 10,000 psi. It uses water or mineral-based hydraulic oil as a source for calibration of high-pressure input devices such as pressure transmitters or pressure gauges. Hydro testing a new water line essentially begins during the design phase. Understanding testing factors during design will enable the water professional to prepare for obstacles that may arise during the fire sprinkler hydrostatic test pump process.

Hydrostatic Test requirements are set by considering the following:

Flow/volume demands

Size and length of pipe

The total overall difference from the low to highest elevations

Changes in elevation or “high spots.

hydro test pump specifications

How To Use a Hydrostatic Test Pump?

The hydrostatic test parameters must be clearly defined during the design phase and stated in the project specifications.

Test pressure shall be 1.25 times the operating pressure. The duration of the test is two hours. Special consideration must also be given when multiple piping products are used.

The test pressure of 300 psi will be detrimental to weak materials, such as polyvinyl chloride (PVC) rated at 125 psi, which also does not have a safety factor of 2 and surge allowance of 100 psi included in the design, compared to the stronger ductile iron that does.

Any material not designed for the specific pressures should not be used and should be isolated from any section of a line to be tested at higher pressures. (hydrostatic test pump 15000 psi).

How to build a hydrostatic test pump?

Attention to Completing a Hydrostatic Test Pump Installation detail is of the utmost importance:

Cleaning the bells, spigots, and gaskets

Proper lubrication of gaskets and spigots

Use of approved accessories

Mechanical Joint installation should include gasket lubrication, straight alignment, and specified bolt torque.

Proper alignment of joints during the homing process – “Straight is great!”

Deflection of joints -after the pipe is homed.

Anyone who has searched for a leak will attest to the importance of proper installation. There is an extremely good chance that the most common installation, a manual hydro test pump.

Hydrostatic Testing WARNING:

The testing methods described in this section are for water-pressure testing only. These procedures should not be applied for air-pressure testing because of the serious safety hazards of compressed air. Also, pipelines intended for buried service should generally be tested with the backfill.

Related products of Hydrostatic Test Pump:

Product technical performances of Hydrostatic Test Pump:

- Pump model: WY-M07

- Pump type: Single head single, acting

- Max pressure: 700 psi @100 psi driving air pressure

- Max. flow rate: 6.36 L/M

- Pressure ratio: 7:1

- Test medium: Clean water, hydraulic oil

- Driven: By compressed air

- Driving air pressure: 100 psi

- Driving air inlet: NPT1/2F

- HP outlet: NPT1/2F

- Dimension: 600L*550W*600H (mm)

- Weight: 20kgs

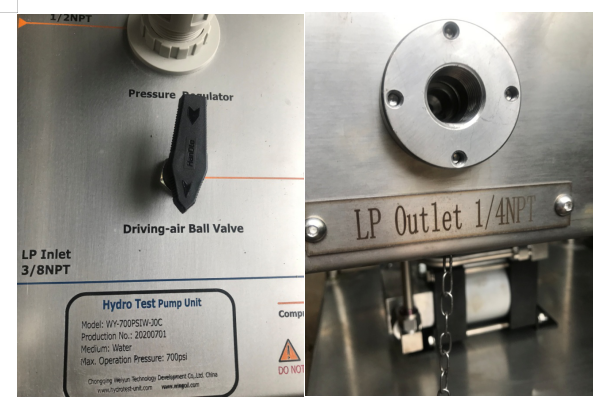

Product Image Hydrostatic Test Pump: