Optimizing Nitrogen Generator Container Units: The Role of an Efficient Control System

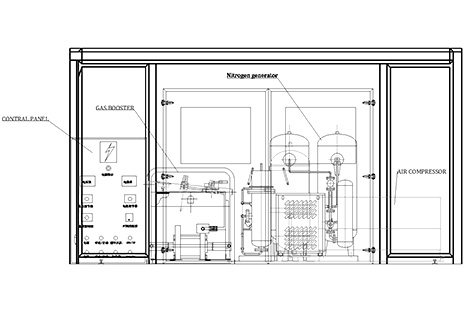

Nitrogen generator container units have become indispensable in various industries that require a reliable and on-site nitrogen supply. These units utilize advanced nitrogen generation systems to produce high-purity nitrogen gas efficiently and cost-effectively. However, to ensure optimal performance, safety, and ease of operation, a well-designed and efficient control system is crucial. In this article, we will explore the significance of a robust control system in nitrogen generator container units and its various components. We will also delve into how nitrogen generator manufacturers prioritize the development of control systems to meet industry demands.

Components of the Control System

The control system of a nitrogen generator container unit consists of several components that work together to deliver precise control, monitoring, and automation capabilities. At the forefront is the user interface, which provides operators with a clear and intuitive control panel. This interface allows users to easily navigate through the control system, adjust settings, and monitor the nitrogen generation process. Nitrogen generator manufacturers prioritize the design of user-friendly interfaces to enhance the overall user experience.

Automation capabilities play a significant role in optimizing the nitrogen generation process. These capabilities enable the nitrogen generator container unit to start and stop automatically based on pre-defined conditions or schedules. Moreover, sensor integration enables real-time monitoring of essential parameters such as flow rate, purity, and pressure, facilitating continuous and accurate control over nitrogen production. This automation eliminates the need for constant manual adjustments, allowing operators to focus on other tasks.

The monitoring and control features of the control system are instrumental in ensuring smooth operation. Operators can closely monitor real-time data on the control panel, providing insights into the performance of the nitrogen generator. Alarms and alerts promptly notify operators of any abnormal conditions, such as low pressure or high temperature, enabling quick response and preventive actions. Some advanced control systems also offer remote monitoring capabilities, allowing off-site monitoring and control, enhancing convenience and efficiency.

Integration and Connectivity are vital aspects of a nitrogen generator container unit’s control system. Manufacturers design their systems to be compatible with existing control systems, such as programmable logic controllers (PLC) or supervisory control and data acquisition (SCADA) systems. This integration facilitates seamless data exchange and communication between different components, enabling streamlined operations. Additionally, communication protocols like Modbus and Ethernet provide reliable connectivity and allow for easy integration into industrial networks.

Operation and Functionality

The control system simplifies the operation of the nitrogen generator container unit through user-friendly interfaces and guided procedures. Operators can easily follow step-by-step instructions for startup and shutdown procedures, ensuring safe and efficient operation. Moreover, setpoint adjustments allow for the customization of nitrogen flow rate, purity, and pressure, ensuring that the N2 generator meets the specific requirements of different applications. These adjustments can be made effortlessly through the control system, granting operators precise control over nitrogen output.

Maintenance and service are essential aspects of any nitrogen generator container unit. The control system assists in ensuring proper maintenance by providing timely reminders for routine tasks such as filter replacements, lubrication, and calibration procedures. Maintenance logs and records are often included, allowing operators to keep track of maintenance history and plan preventive maintenance accordingly. Troubleshooting and diagnostic features within the control system help identify and resolve common issues quickly, reducing downtime and maximizing productivity.

Safety Features and Emergency Shutdown

Safety is of paramount importance in nitrogen generator container units. The control system incorporates safety interlocks and safeguards to prevent overpressure, overheating, or other hazardous conditions. In the event of a critical failure or malfunction, emergency shutdown procedures can be initiated through the control system, ensuring the safety of personnel and equipment. Nitrogen generator manufacturers adhere to safety standards and regulations to provide a reliable and secure operating environment.

User Training and Support

To assist operators in making the most of the control system, nitrogen generator manufacturers offer comprehensive user manuals and documentation. These resources provide in-depth explanations of the control system’s functionalities, operation procedures, and troubleshooting guides. In addition to documentation, manufacturers often provide training programs or resources to ensure that operators are well-trained in utilizing the control system effectively.

Technical support channels are also available to address any concerns or issues that operators may encounter. Manufacturers typically offer multiple avenues for technical support, including phone assistance, email support, and online forums. These support channels allow operators to seek guidance, receive prompt responses, and collaborate with experts to resolve any challenges they may face.

Conclusion

An efficient control system is a vital component of nitrogen generator container units, optimizing their performance, safety, and usability. With user-friendly interfaces, automation capabilities, and real-time monitoring, operators can easily control and monitor the nitrogen generation process. Integration and connectivity features facilitate seamless integration into existing control systems, enhancing overall operational efficiency. Moreover, maintenance and diagnostic functionalities simplify maintenance procedures and troubleshooting, minimizing downtime.

Nitrogen generator manufacturers prioritize the development of robust control systems to meet the specific demands of various industries. By providing comprehensive documentation, training programs, and technical support, manufacturers ensure that operators are well-equipped to operate the control system effectively.

As industries continue to rely on on-site nitrogen generation for a wide range of applications, the role of an efficient control system in nitrogen generator container units becomes increasingly critical. By investing in advanced control systems, manufacturers empower operators to optimize nitrogen production, enhance safety, and streamline operations, ultimately contributing to improved productivity and cost-effectiveness.