Valve Testing: Ensuring Industrial Valve Safety and Peak Performance

In industrial production and piping systems, valves serve as crucial components for controlling the flow of fluids, and their performance directly affects the safety and stability of the system. Valve testing is an essential process to ensure the reliability and durability of valves. By employing scientific testing methods, it evaluates the valve’s sealing performance, strength, and leakage, providing safety assurance for industrial enterprises.

Part 1. What is Valve Testing?

Valve testing is the process of evaluating a valve’s performance under actual operating conditions. It primarily includes pressure testing, sealing performance testing, and leakage testing. Through these tests, the valve’s ability to operate under high, medium, and low pressures can be verified, as well as its compliance with design standards and industry regulations.

Common types of valves suitable for testing include:

- Gate Valve

- Ball Valve

- Globe Valve

- Check Valve

- Plug Valve

Part 2. Why Valves Testing is Essential?

Checking compliance really adds value. In most industrial processes that valves are associated with, compliance testing should be an integral part of testing. This is important for the following reasons:

Ensuring the Safety of Piping Systems

Too rapid fluid flow past a valve may set off dangerous slam, shock, or sudden pressure change waves within the system. It could occur, among other ways, allowing liquid flow in water applications at a speed exceeding 75 feet per second or holding back a fluid flow upstream of a fluid velocity greater than 175 feet per second in large gas applications.

Verifying Valve Pressure Resistance

Pressure testing allows engineers to confirm that a valve can withstand its designed operating pressures. This prevents damage, deformation, or failure during normal operation, maintaining system integrity under high, medium, or low pressure conditions.

Compliance with Industry Standards and Regulations

Industries like the oil and gas, chemical processing, nuclear power, and marine engineering impose stringent criteria for valve safety and performance. Valve testing counted among the necessary parts of factory quality control and acceptance inspection is appreciated as essential to ascertain adherence to both design specifications and regulatory standards.

Prolonging Valve Longevity

Should any irregularity wear, corrosion, or minor leaks detect in a valve, it will escalate into a major opportunity loss if the same is not addressed. It effectively shortens the valve’s service life and exponentially spreads maintenance and downtime costs for various industrial systems.

Part 3. Common Valve Testing Methods

Tests of valves use multiple techniques that are aimed to evaluate various aspects of valve performance like strength, sealing ability, and operational robustness. Through the use of the desired testing method, a valve can, with confidence, be tested for compliance with design standards and for its safety while performing optimally.

Method 1. Hydraulic Testing

Using water or hydraulic oil as a medium to detect leakage and assess the strength under pressure for a valve. Thus, this test imitates the high pressure operational conditions and is probably the most critical test concerning industrial valves.

The valve is required to be tested at a pressure in excess of its normal operational range to verify that the valve can stand up to those rigorous conditions without leakage or deformation.

Method 2. Pneumatic Testing

Pneumatic test is when air or an inert gas is been used to determine leaks mainly on valves of low or medium pressures. It is highly effective at idenfying very small leakages early, thereby facilitating any test that may need done to evaluate any possible problem before setting the tested valve.

Method 3. Functional Test

Functional test then confirms whether the valve works correctly and in response. Includes checking functions of the opening and closing functions; actuator; safety valves work correctly. This is especialy critical with regard to automated control valves and safety-critical applications.

Method 4. Shell and Seat Test

Shell Test: an evaluation of the valve body to withstand internal pressure without deformation, cracks or rupture.

Seat Test: a test on the seats for air leakage in high-pressure or hazardous media applications.

Part 4. Applications of Valve Testing Across Industries

Valve testing is a crucial procedure across various industries, which are requisites necessary to assure system safety, operational reliability, and code compliance. Some of the big applications encompass:

1. Oil and Gas Industry

Valve testing ensures secured transportation of crude oil, natural gas, and other hydrocarbons in oil and gas pipeline and wellhead systems.

By verifying the valve’s ability to contain pressure and seal strength, tests are very crucial to preventing costly leakages and subsequent liabilities, such as polluting the environment, which is paramount inshore as well as offshore operations.

2. Chemical and Petrochemical Industry

Valves are substituted with hazardous chemicals; so testing is an absolute must to avoid leakages and subsequently maintain production safety in the chemical processing plants.

Properly tried and tested valves ensure the effective containment of highly corrosive or toxic materials: the resultant disasters thereby decrease due to lesser harm to equipment, accidents, and environmental contamination.

3. Nuclear Power and Power Generation

In nuclear and conventional power plants, valves are often critical safety components controlling steam, coolant, and other high-pressure fluids. Testing these valves under actual pressure conditions ensures their durability and proper function, contributing directly to plant safety and regulatory compliance.

4. Mechanical Manufacturing and Hydraulic Systems

Hydraulic circuits, that include everything from hydraulic valves to on-off valves, air-control valves, etc., must go through rigorous testing to establish their operational perfection.

Hydraulic valves can maintain separation with pressure, have high level-of-flight ranges, meet endurance requirements in medium-duty cycles for dynamic loads. These valves must provide accurate control under wide-ranging operating conditions.

5. Marine and Water Treatment Equipment

Valves are indispensable for regulation of flow of fluids and ensuring system integrity on ships, offshore platforms, and water treatment facilities. Valve testing ensures reliability and safety in tough marine environments and critical water processing applications, preventing leaks, and system failures that can seriously disrupt operations.

Part 5. How to Select the Proper Valve Test Bench?

It is extremely important to choose the right valve test bench for getting accurate test results, safety, and efficiency. Factors for consideration include:

1. For optimal match

The size and design of the valve will in large measure determine the type of test bench that will be needed. Testing of large, standard valves would be best effected on a horizontal test bench, thus affording the large valves extra curricular accommodation of weight and balance space for hydraulic and pneumatic tests.

Smaller valves, however, may include safety valves and/or delicate valves, and testing would best be achieved using a vertical test bench wherein precise positioning may be performed for functional tests and minor leakage tests of the compact and delicate components.

2. According to Test Medium

For the actual service of the said medium, be it air, water, or oil, our hydraulic testing with water or oil is ideally suited to high-pressure situations while pneumatic tests with air or inert gas are appropriate for low- to medium-pressure.

Taking care to use the right test medium for the operating condition of the valve is what ensures the accuracy of data and thereby allows the test results to reflect real-world performance.

3. Automation Grade and Safety Features

Automated test benches can increase accuracy, reduce chances of human errors in tests, and boost the safety of the operator.

Their automated pressure operations and coordinated actuator control, as well as real-time data recording mechanisms, provide provisions for repeatable, consistent testing while reducing manual interference and potential risk elements.

4. The Customization Features and Ease of Operation

Towards this end, test benches with multiple customization features and specs, e.g., adjustable pressure ranges, control modes, and interface configurations, will match a broad spectrum of valves and peculiar testing requirements.

Moreover, these designs’ ease of use and provision for integrated data storage and management further support the possibilities of recording test results, with provision for maintenance tracking and simplified quality control.

Part 6. Wingoil Valve Test Bench – Your Reliable Choice

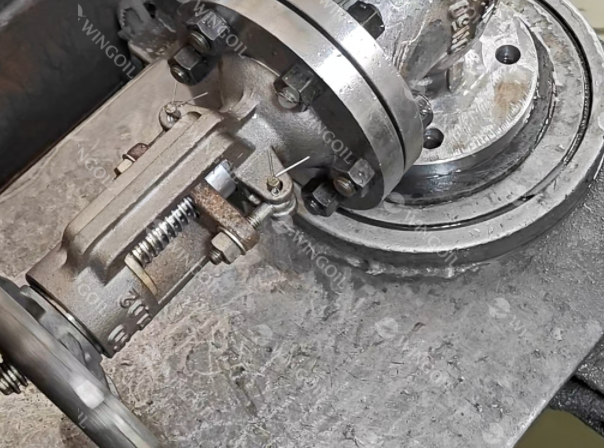

Wingoil Valve Test Bench serves the profession of a specialized valve test bench manufacturer, incorporating electromechanical, hydraulic, and pressure test fluid-based storage and circulation system assembly.

It offers many other features plus stable performance with a high degree of automation, meeting the testing requirements imposed on various industrial valves. The entire testing process is held through hydraulic transmission and electrical systems with pressure applied, with no other external force. Such circumstances guarantee accurate and reliable test results.

Main advantages include:

Multiple Media Compatibility: With water, gas, and oil available, it can benefit testing an immense variety of valve types to numerous industrial applications.

High-precision Pressure Testing: Sealing test pressure exceeds an upper limit of 25 MPa and strength testing pressure goes as far as 37.5 MPa, accommodating high, medium, and low airtight valves.

Compatibility with Multiple Valve Types: Shell tests, top seal tests, high-pressure water seal tests, and low-pressure air seal tests applied for the gate valves, ball valves, globe valves, check valves, and plug valves.

Automated Control: Graduation of pressure gauges and water-control valves and buttons have been centralized upon a control panel. All operations can be managed simultaneously so as to control the mechanisms interdependently, thereby making it an easy, safe, and reliable project.

Modular Design: The bench design is built upon modular concepts such that it is divided into hydraulic, mechanical, and electrical control systems, thereby making it easy for maintenance and upgrading while maintaining a stable and efficient testing system.

Wide Application Range: Their broad range of applications stands undeniable as they are being applied for test and calibration purposes on flange globe valves with an internal nominal diameter ranging from DN15 to DN300, thereby covering various demands in industrial production.

Wingoil Valve Test Bench, when woven with mentioned attributes, not only enhances the efficacy of testing valves, but also brings about the most preferred choice for the global industrial sector when it comes to industrial valve testing, thereby promising industrial enterprises, a great deal of quality assurance.

Part 7. Valve Testing: Operating and Maintenance Recommendations

Operational and maintenance activities need to be properly carried out so that the testing of valves can be measured, to increase the life of testing equipment, and to assure the safety of valves.

The main requirements to be maintained include:

Regular Calibration of Pressure Gauges and Test Pumps

Pumps, pressure gauges, and other measuring devices shall be calibrated at regular intervals so that correct and accurate results are obtained. Inaccuracy at calibration will mean that applied pressure is wrong in terms of control optimality. Wrong assessment of valve performances are courtesy of misreading of pressure.

Following Standard Operating Procedures

All testing consulting to valves – be it pressure testing, seepage test, or leak testing- needs to be conducted with compliance only with standard protocols and procedures.

Compliance with standardized procedures provides the same results each and every time, minimizes the chance of causing damage from human error, and minimizes some risks due to equipment malperformance.

Choose the Right Test Medium and Pressure Range

Choose a medium of testing-water, air, or oil-based on the environment in which the valve will be operated. Make sure you do not exceed the valve’s rated pressure rating-demanding the proper media and the pressure range will eliminate unwarranted wear and also destruction or failure of the valve during testing.

Regular Maintenance of Test Equipment

Regular maintenance must be bestowed upon valve test beds and associated systems, including cleaning, lubrication, and checking of pumps, valves, hoses, and control systems. Proper maintenance ensures equipment reliability, extends its service life, and most importantly, maintains a safe test environment for operators.

Final Thoughts

Valve testing is an indispensable part of industrial production and piping systems. By employing scientific and professional testing methods along with Wingoil’s automated valve test benches, the safety, reliability, and service life of valves can be effectively ensured.

Investing in Wingoil‘s high-performance valve test benches not only enhances product quality but also reduces safety risks, improves the stability of industrial piping systems, and strengthens customer confidence.