What is the Difference Between a Dissolvable Frac Plug and a Dissolvable Bridge Plug?

In the intricate realm of hydraulic fracturing, dissolvable frac plugs, and dissolvable bridge plugs play pivotal roles in isolating different sections of the wellbore, facilitating the creation of multiple fracture stages, and enhancing overall well performance. While both serve similar purposes, they exhibit distinct characteristics and applications, making it crucial to delve into their intricacies to grasp their true value.

What are Dissolvable Frac Plugs?

Dissolvable frac plugs, also known as dissolvable bridge plugs or dissolvable frac balls, are ingenious devices employed in hydraulic fracturing operations. These specialized plugs are strategically positioned within the wellbore to isolate specific zones, enabling controlled fluid injection and fracture initiation. Crafted from a unique blend of materials designed to dissolve under specific downhole conditions, these plugs offer a multitude of benefits over conventional mechanical plugs.

What are Dissolvable Bridge Plugs?

Dissolvable bridge plugs, akin to dissolvable frac plugs, excel in isolating specific sections of the wellbore during hydraulic fracturing. However, they differ in their placement and functionality. Bridge plugs are typically installed at the junction between different wellbore sections, effectively sealing off unwanted communication paths and preventing fluid migration. Their dissolvable nature eliminates the need for costly milling operations, streamlining the well completion process.

A Comparative Analysis of Dissolvable Frac Plugs and Dissolvable Bridge Plugs

To better understand the nuances between these two dissolvable tools, a comparative analysis of their key features is essential:

| Feature | Dissolvable Frac Plugs | Dissolvable Bridge Plugs |

| Size | Smaller, typically ranging from 1.25 inches to 2.5 inches in diameter | Larger, typically ranging from 3.5 inches to 7 inches in diameter |

| Location | Primarily used in horizontal and extended-reach wells | Primarily used in vertical and deviated wells |

| Application | Isolating individual fracture stages in multi-stage fracturing operations | Isolating larger zones within the wellbore, such as preventing communication between zones |

Applications of Dissolvable Frac Plugs: Unleashing Their Potential

Dissolvable frac plugs find widespread applications in hydraulic fracturing operations, enhancing well performance and streamlining operations. Their primary applications include:

- Isolating fracture stages: Dissolvable frac plugs effectively isolate individual fracture stages, ensuring precise fluid injection and controlled fracture initiation.

- Enabling multi-stage fracturing: By isolating each fracture stage, dissolvable frac plugs facilitate the execution of multi-stage fracturing, a technique that enhances well productivity.

- Optimizing wellbore integrity: The ability to dissolve and disappear without residue eliminates the need for costly milling operations, maintaining wellbore integrity and reducing operational risks.

Applications of Dissolvable Bridge Plugs: Harnessing Their Versatility

Dissolvable bridge plugs offer a range of valuable applications in hydraulic fracturing operations, ensuring well stability and enhancing productivity. Their key applications include:

- Isolating unwanted communication paths: Dissolvable bridge plugs seal off unwanted communication paths between different wellbore sections, preventing fluid migration and ensuring well stability.

- Protecting casing integrity: By isolating zones with potential integrity issues, dissolvable bridge plugs safeguard the wellbore casing from potential damage.

- Facilitating well interventions: Dissolvable bridge plugs enable safe and efficient well interventions by isolating specific zones, minimizing operational downtime.

Dissolvable frac plugs and dissolvable bridge plugs offer a plethora of advantages over conventional mechanical plugs, but they also present certain drawbacks.

Advantages and disadvantages of dissolvable frac plugs

Advantages:

- Eliminate the need for milling operations, reducing operational costs and environmental impact

- Provide precise control over fracturing operations

- Reduce the risk of fracturing into unwanted formations

Disadvantages:

- Limited pressure and temperature tolerance compared to permanent plugs

- Potential for premature dissolution in certain well conditions

Advantages and disadvantages of dissolvable bridge plugs

Advantages:

- Provide a long-lasting barrier between wellbore sections

- Eliminate the need for future milling operations

- Reduce the risk of fluid migration and wellbore integrity issues

Disadvantages:

- Higher initial cost compared to dissolvable frac plugs

- Limited pressure and temperature tolerance compared to permanent plugs

- Potential for premature dissolution in certain well conditions

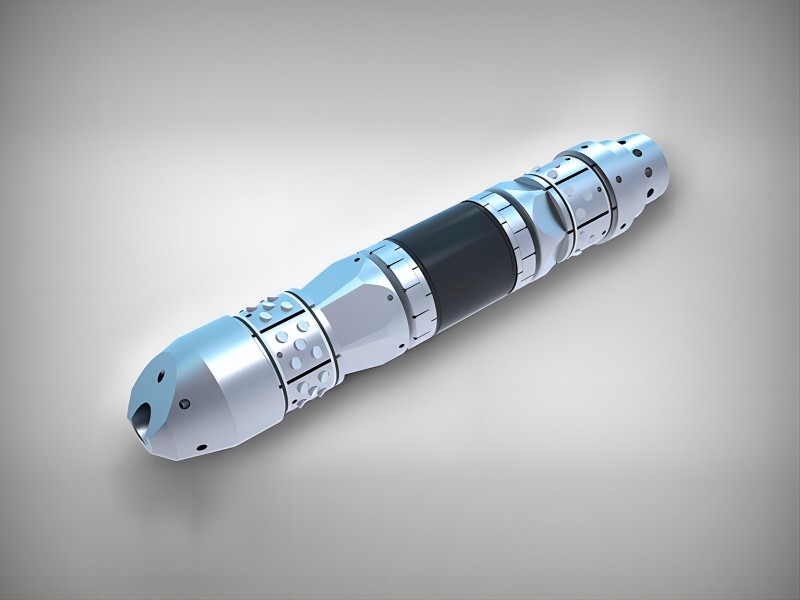

Dissolvable bridge plug

Conclusion

Dissolvable frac plugs and dissolvable bridge plugs have revolutionized hydraulic fracturing operations, offering a multitude of benefits over conventional mechanical plugs. Their ability to dissolve without residue eliminates the need for costly milling operations, reducing operational risks and enhancing wellbore integrity. While each type of plug possesses unique advantages and limitations, careful consideration of wellbore conditions, application requirements, and cost factors will guide the selection of the most suitable solution. As technology advances, dissolvable frac plugs and dissolvable bridge plugs will continue to evolve, further enhancing well performance and streamlining operations in the ever-evolving field of hydraulic fracturing.