What Keeps the Oilfield Pipeline From Leaking?

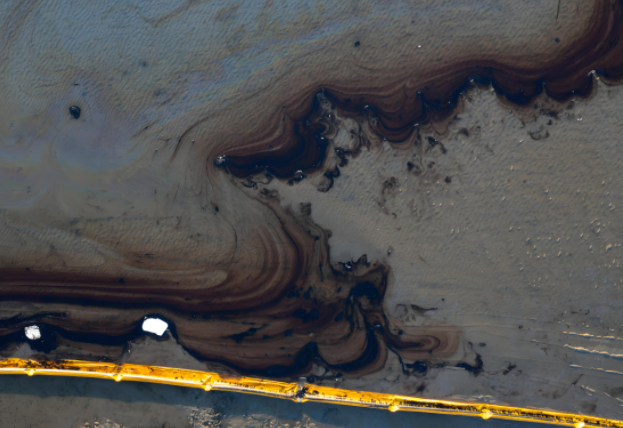

Oilfield pipelines serve as the backbone of production, being continually exposed to extreme conditions like high pressure, elevated temperatures, and corrosive substances. Even an undetectable leak can become an imminent safety threat and must therefore be eliminated in order to ensure production success. Preventing pipeline leaks remains a top priority throughout the oil and gas industry.

In this article, we will delve into the common causes of pipeline leaks in oilfields and explore what keeps the oilfield pipeline from leaking. Let’s take a closer look!

Part 1. Main Causes of Oilfield Pipeline Leaks

Before we get into the subject we must first understand the common causes that result in leaks in pipelines for oilfields.

When it comes to extraction of gas and oil and transport, pipeline systems are exposed to long periods of stress. Even a slightest defect can escalate into a serious leakage incident. Leaks usually found at pipeline connection points The main reasons are:

1. Poor Threaded Connection Sealing

Casing and tubing used in oilfields are typically joined using threaded joints to ensure strength of the joint and seal. However, when the threads are not properly machined, have rough surfaces, or an excessive clearance, tiny leak paths can be created.

Furthermore, the effectiveness and quality of sealants are crucial. If sealing materials such as PTFE tapes or sealants made of liquid are not properly selected or deteriorate over time, they may fail at high temperatures and pressures.

2. Material Aging or Damage

Pipeline components are subject to a mix of chemical and physical stresses. When exposed to constant extreme pressure and corrosive media, metal components may develop pitting, fatigue cracks, and stress corrosion. They can also cause tiny cracks in the pipe’s wall. When these problems arise, they can quickly develop into leaks or more serious structural issues.

3. Improper Installation

The environments in oilfields are typically rough and unpredictable, which makes an effective installation crucial. Any defects in the assembly process, like inadequate or excessive tightening of threads or rings, incorrect alignment, or missing sealing rings or welding that is not up to par, could cause damage to the seal’s integrity.

In deep-sea installations, in particular the installation process, mistakes can be expensive and difficult to fix later on and could pose a significant risk.

4. Impact of Extreme Operating Conditions

Complex geological formations may cause pipelines to be exposed to harsh conditions, such as high temperatures as well as high pressures, and high hydrogen sulfide levels with high content of water.

In these circumstances, sealing systems undergo more stress, and conventional methods and materials may not be sufficient. In addition, well-functioning procedures, such as fracturing or testing, can cause high-speed cyclic loads to the system, leading to stress on the sealing components.

The two factors are often together, not separated, slowly diminishing the strength of the pipeline over time. A tiny seal defect could quickly turn into a severe leak when exposed to high-pressure fluid scouring.

Thus, each step, starting with design, material selection, manufacturing, installation, to periodic checking and maintenance, has to be closely monitored. Then, we can efficiently stop leaks in pipelines and assure secure, reliable, and long-lasting oil and gas production.

Part 2. How to Prevent Oil Pipeline Leakage?

Now that we understand the main causes of leaks, most of which occur at pipeline connection points. Therefore, what can keep oilfield pipelines from leaking? Don’t worry, in the following sections, we will provide you with a detailed introduction.

1. Use of High-Quality Sealing Materials

Effective sealing starts with the right materials. Oilfield environments often involve extreme conditions such as high temperature, high pressure, and corrosive fluids like hydrogen sulfide or saltwater. Therefore, gaskets, sealing rings, and thread compounds must be made from materials that can withstand these challenges.

For example, elastomers like Viton or metal-to-metal seals are commonly used due to their durability, chemical resistance, and thermal stability. For threaded joints, specialized thread sealants or dopes with anti-corrosive and high-pressure properties are essential to ensuring a long-lasting, leak-free connection.

2. Strict Process Control in Manufacturing and Installation

Precision in machining and installation is critical. During pipe threading, any misalignment, burrs, or improper tolerance can compromise sealing integrity. To address this, manufacturers implement strict quality control processes such as precision CNC machining, surface treatment (e.g., phosphating or nitriding), and non-destructive testing of threads.

During field installation, torque specifications must be followed precisely, and all connections must be properly cleaned, lubricated, and sealed to prevent future leaks. Operators are trained to follow standardized procedures and checklists, minimizing the chance of human error.

3. Adoption of Advanced Leak Detection Technologies

While high-quality materials and careful installation reduce the likelihood of leaks, detection systems are essential for identifying hidden or developing issues. Advanced leak detection technologies serve as the final safeguard in the sealing system. These include:

Helium Leak Detection: Using helium gas as a tracer, this method can detect extremely small leaks that traditional methods might miss. Helium is non-toxic, non-flammable, and has small atomic size, allowing it to escape through the tiniest of openings.

Pressure Decay Testing: This method involves pressurizing the system and monitoring for pressure drops, which can indicate a leak.

Ultrasonic Leak Detectors: These devices pick up the high-frequency sound of gas escaping through a leak point, even when the leak is invisible to the eye.

Among these, helium gas testing equipment for casing and tubing threads has become a particularly important tool. Due to its high sensitivity and precision, helium leak detection is widely used in quality inspection stages to ensure that threaded connections are truly airtight. This technology plays a vital role in catching potential defects before pipelines are deployed in the field.

In short, leak prevention is not about relying on a single solution, but rather building a complete system of reliable materials, accurate engineering, and smart testing. Each link in the chain reinforces the next, forming a comprehensive defense against oilfield pipeline failures.

Part 3. Wingoil Helium Gas Casing and Tubing Thread Seal Test Equipment – Your Trusted Choice

If you are looking for efficient and reliable leak detection equipment, Wingoil Helium Gas Casing and Tubing Thread Seal Test Equipment can be your trusted choice.

It uses high pressure to mix helium with nitrogen at a pre-set testing pressure. A dual-seal detection packer is deployed to the threaded connection of the downhole tubing string, forming a tight seal once activated.

Then, high-pressure helium is injected into the packer, and the external high-sensitivity detector takes advantage of helium’s small molecular size and ease of escape to accurately test the sealing performance of casing and tubing thread connections, effectively ensuring there are no leak risks.

Key Features of Wingoil Leakage Detection Equipment

Ultra-High Sensitivity: Detection sensitivity reaches a helium leakage rate of 1×10⁻⁷ Bar·ml/sec, capable of capturing extremely small leaks and preventing potential safety hazards.

Safe and Environmentally Friendly: Helium is an inert gas, lighter than air, non-corrosive, and harmless to both equipment and operators.

Efficient and Convenient: The average testing time per tubing segment is only about 2 minutes, enabling rapid inspections without affecting subsequent downhole operations.

Wide Applicability: Supports multiple thread sizes (such as 2-3/8″, 2-7/8″, 3-1/2″, 4-1/2″, etc.) and is compatible with mainstream thread standards including FOX, BGT, and VAM. Suitable for casing, tubing, Christmas tree assemblies, pipelines, and various other scenarios.

Durable and Reliable: Features a patented design with a steel cylinder and rubber seals, providing fast sealing and high pressure resistance (70Mpa/10,000 psi). It can be used continuously for more than 300 cycles, ensuring long-term stable operation.

Final Words

Leak prevention in oilfield pipelines is a systematic process. Only through multi-layered and comprehensive protective measures can the safe operation of oilfield pipelines be effectively ensured, preventing leakage incidents.

If you want to learn more about oilfield pipeline leak prevention technologies or seeking professional oilfield equipment services, please feel free to contact Wingoil. We are dedicated to providing you with the best solutions.