6 Basic Information About Hydraulic Testing Pump

Introduction

The hydraulic testing machine can be used in various industries including hydrostatic testing of gas cylinders, pressure vessels, various valves, various pipes, and special tools for some industries, such as blowout preventers for the petroleum industry, wellhead equipment, and other various tools. It is especially suitable for equipment manufacturers to do product production testing and scientific research and testing institutions to verify equipment.

What Are Hydro Testing Pumps?

Hydro testing pumps are a common procedure used to check fluid pressure vessels, such as cylinders, boilers, tubes pipe, valves, castings, components, etc. Hydrostatic testing pumps are also a common testing procedure to verify pressure vessels do not leak or have manufacturing flaws. Hydro testing pumps & units are important for pressure vessels in the interest of device safety, and durability under operating pressure.

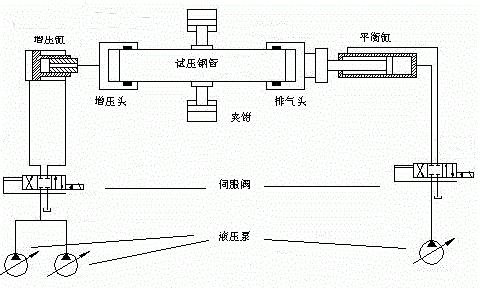

The Working Principle Of Hydraulic Testing Pump

Taking the principle of the gas cylinder hydrostatic testing machine as an example, it uses a pneumatic liquid booster pump to pressurize the inside of the gas cylinder, and when the pressure is increased to the set pressure, it will automatically stop, and carry out a pressure maintenance test. At the same time, the external test method test device is equipped with an expansion detection device (with external test method water jacket), and the computer can automatically calculate the total volume deformation and volume residual deformation of the gas cylinder, and output standard test reports and curves etc.

What Materials Can The Hydraulic Testing Pump Test?

1. Metals: steel pipes, copper pipes, steel cylinders, aluminum pipes;

2. Non-metallic: plastic pipe, composite pipe, cement pipe, rubber pipe;

3. Use type: inflatable pipe, small diameter pipe, steam pipe, U-shaped pipe, air conditioning pipe, spiral pipe

What Is The Function Of a Hydraulic Testing Pump?

The function of the hydraulic testing machine is mainly reflected in the safety and reliability of product use, such as through testing, measurement, calibration, and outside. The inner side and other test methods are used to test the performance of high-end, static resistance, standard, explosion-proof, safety, high resistance, slow down, and precision.

What Types Of Hydraulic Testing Pumps Are There?

In the current testing machine market, the most commonly used hydraulic testing machines are plunger type, fixed type, mobile type, etc., which can perform mortgage, static pressure, decompression, static, pneumatic, dynamic, and ultra-high pressure on the valve. Wait for the test performance to be tested.

Features Of Hydraulic Testing Pump

1. The booster pump can easily realize any adjustable and controllable output pressure and has a memorized instrument to record the instantaneous burst pressure.

2. Advanced technology and reasonable structure design. It has the characteristics of small size, lightweight and beautiful appearance.

3. All pressure-bearing parts are standard parts of international famous brands, without any welding connection, easy to disassemble, have high safety factor, long life, and easy maintenance.

4. Manual control, digital pressure gauge display, computer control, and other operation modes can be selected.

Conclusion

At WINGOIL, hydrostatic testing machines can also provide product performance such as hydrostatic tests, hydrostatic blasting, hydrostatic strength, hydrostatic rupture, high-pressure test, and so on. We continue to innovate and improve technology to provide customers with safe and reliable pressure test equipment. If there are any questions, please feel free to contact us!