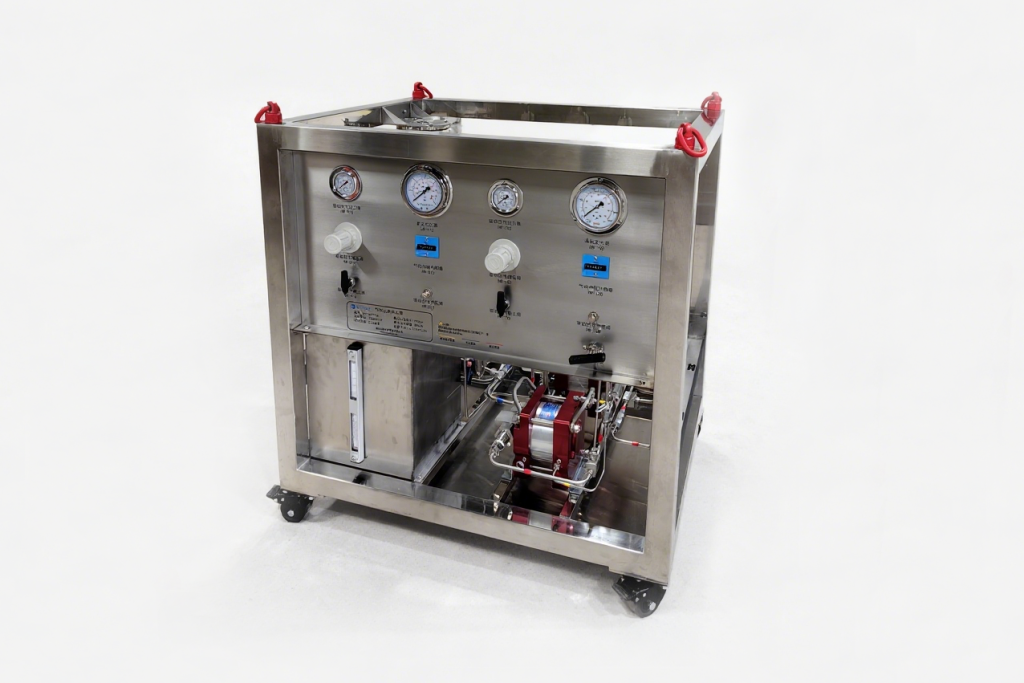

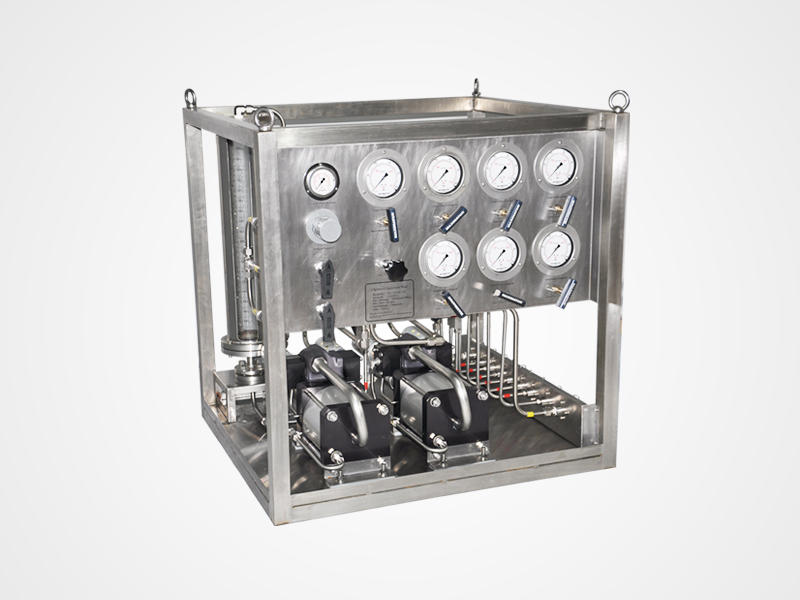

Chemical Injection Package

- Model: WY-8C-TJ1-L / WY-8C-TJ1-H / WY-10C-TJ1-L

- The main components of the Chemical Injection Package include an open skid-mounted structure, dosing part, storage tank part, control part, and eyewash station

- The control methods of the package are mainly divided into manual control and automatic scheduled task control

- Stable three-phase AC power supply is required for the normal operation of the package

Share to

Overview

The package is divided into three major systems: liquid storage tank, pump and pipeline, and electrical system. The liquid storage tank system includes chemical storage tank, mixer, liquid level meter and other components. The pump and pipeline system includes flow calibrator, Y-shaped filter, precision metering pump, pulse damper, safety valves, pipelines and pipeline valves and other components. The electrical system mainly includes local automation operation, remote operation, data recording, etc. The three major systems are generally integrated in the same skid, and each system can be customized according to specific needs.

Advantage

- One mechanical diaphragm metering pump for use and one for standby.

- One independent pipeline energy storage device for use and one for standby.

- All pipelines are made of 316 material.

- The connection between fluid components and pipelines adopts the ferrule method, which is convenient for later tightening and replacement.

- The open skid-mounted structure is convenient for maintenance.

- The bottom of the skid is designed with a 20mm sump pit to prevent leakage of chemical.

- The top of the skid is designed with a sun shading board to block some direct sunlight and rain.

- The flow rate can be infinitely adjusted within the range of 0-100%, and precisely adjusted within the range of 10-100%.

- The device can set up scheduled tasks through the control panel.

- When the package malfunction occurs, a fault code will be generated in real time and the alarm buzzer will sound.

- A set of external PLC module is reserved inside the package for users to connect to the main control system.

FAQ

| ① Driving air source pressure is too low (Driving Air Source Pressure * Boost Ratio = High-Pressure Outlet Pressure) | a. Check whether the driving air pressure reaches the rated value. b. Listen for air leaks or abnormal noises in the air loop. c. Adjust the driving air pressure to the required value. |

| ② Filter—Pressure Regulator Component Failure | Check if the pressure regulator filter is blocked or if there is water accumulation. |

| ③ Pressure fluctuations | a. Observe the pressure gauge at the outlet of the pressure regulator to ensure the pressure remains stable at the rated value. b. Consider adding pressure stabilization protection as needed, such as installing a small pressure buffer tank to absorb momentary pressure fluctuations and ensure stable air pressure at the pump end. |

Model: WY-8C-TJ1-L / WY-8C-TJ1-H / WY-10C-TJ1-L

Model: WY-8C-TJ1-L / WY-8C-TJ1-H / WY-10C-TJ1-L

| Medium | Oxygen Scavenger, Biocide, Corrosion Inhibitor Demulsifier, Scale Inhibitor, Water Clarifier |

| Dimension | L2300 * W1800 * H2100 |

| Weight | 850KG |

| Ambient temperature | -10 to 50 ℃ |

| Power supply | AC400V 50HZ 3φ |

| Max. pressure | 0.8 Mpa / 1 Mpa |

| Max. flow rate | 20L/h / 25L/h |

| Storage tank volume | 1000L |

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————