Chemical Injection Unit for High Flow Rate

- WINGOIL Chemical injection is a process whereby a secondary chemical solution is added to the primary process flow to improve the primary fluid quality or to enhance the flow of primary fluid. The main -material is glass and 316s to meet the corrosion-proof requirements.

Share to

Overview

In various industries such as oil and gas, petrochemical, and water treatment, the precise and reliable injection of chemicals is critical for maintaining operational efficiency and meeting regulatory requirements. When high flow rates are required, specialized equipment known as chemical injection units come into play. These units are designed to handle large volumes of chemicals and deliver them accurately and consistently into the system.

Feature

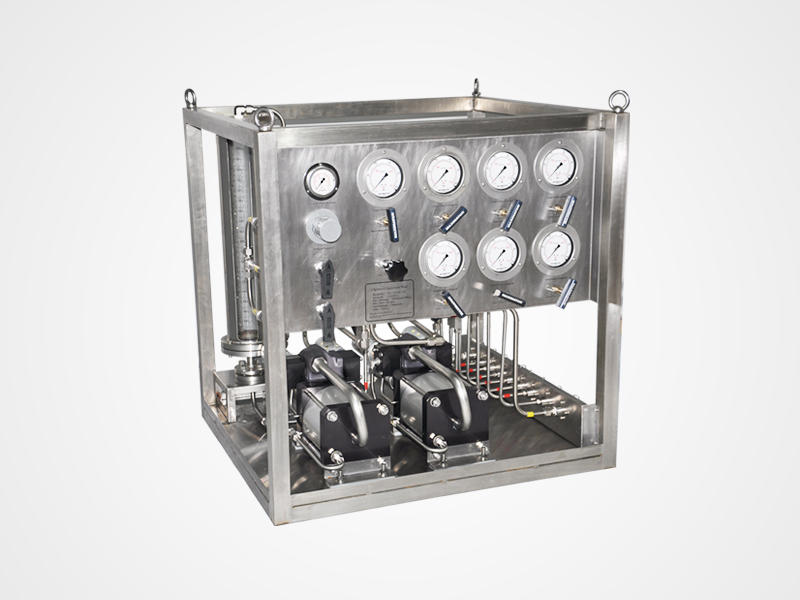

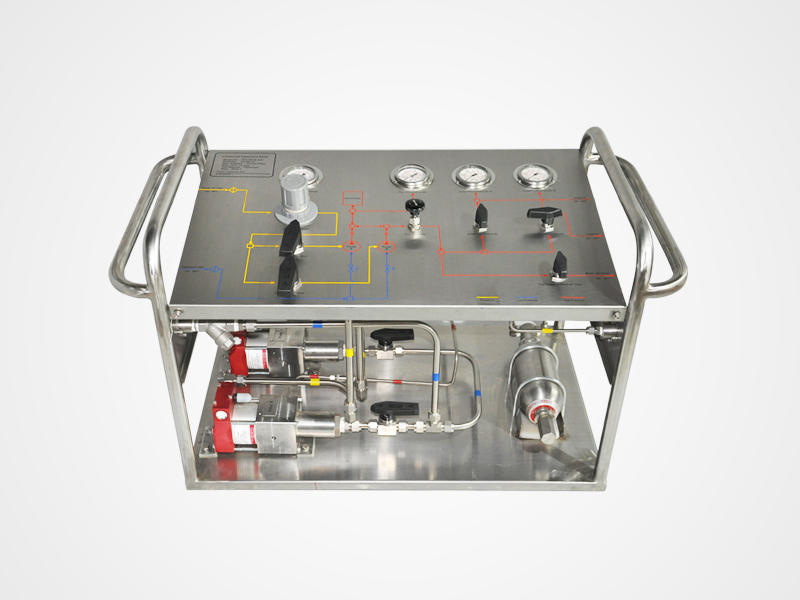

- With shockproof and dual scale display pressure gauge.

- Low-pressure compressed air as a booster power source to keep convenience and safety.

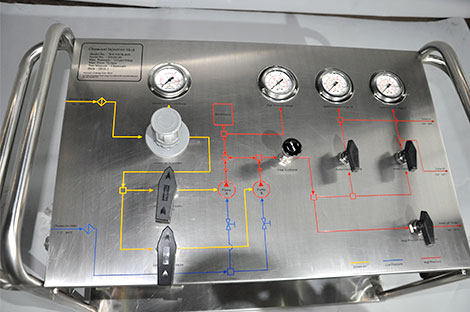

- Has an operation schematic on the control panel, which is easy to observe and operate.

- All components, piping, and valves are made of 316s or 316L, which can prevent corrosion effectively.

- Adopted pressure to be self-locked to adjust output pressure keeps constant in case of overshoot under air-driven pressure setting constant.

- Equipped with a glass column and high-precision flow control valve to meet the requirements of high flow rate chemical injection. The main -materials are glass and 316s to meet the corrosion-proof requirements.

| Chemicals | Anti-frozen agent, viscosity reducer, blocking remover, biocide chemicals, oxygen scavenger, pour point disperant(PPD), anti-corrosion agent |

| Pressure | 0 to 2000 bar / 29,000 PSI |

| Flow rate | 0 to 24L/min (customize) |

| Pressure accuracy | ±1%FS |

| Ambient temperature | -20℃ to 65℃ |

| Application | Surface low pressure, downhole high pressure |

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————