Everything you have to know about the ball check valve

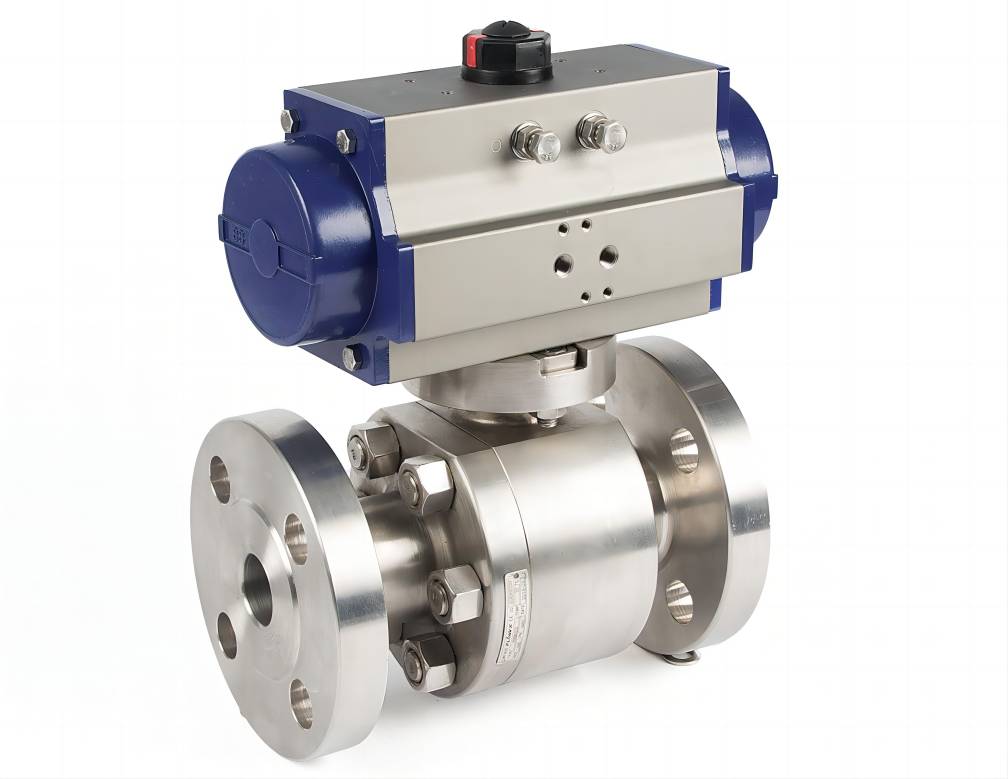

What is a ball check valve?

The ball check valve is a one-way valve that permits fluids to flow in only the desired direction opening the valve, while backflow forces the valve closed to block the reverse flow. It is built with an internal guidance system that entirely removes the rubber-coated ball from the flow path, resulting in optimal performance and minimal pressure drop.

It is the most used check valve for preventing backflow in both municipal and industrial settings. With spring-assist closing, hydraulic cushions, and other accessories utilized to prevent the check valve from slamming, the straightforward and economical design eliminates the need for pricey swing-type check valves.

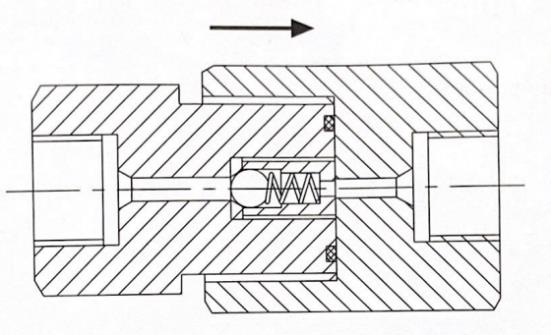

How does the ball check valve work?

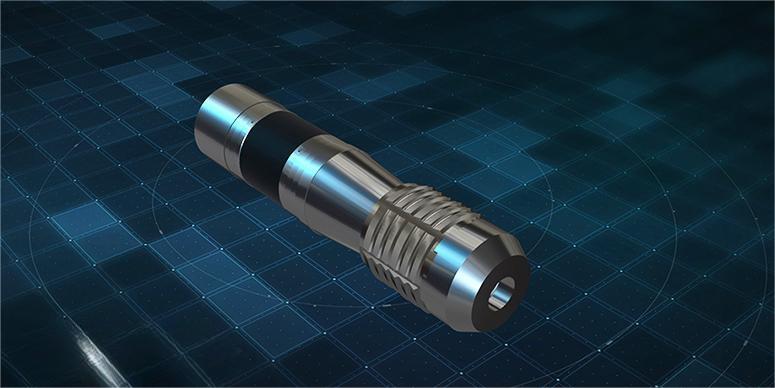

A spring-loaded or free-floating ball that sits on the sealing seat is used by a ball check valve to close the valve opening. To help the ball enter the sealing seat and form a positive seal that prevents reverse flow, the sealing seat is conically tapered. The ball is knocked out of its seat and fluid flow begins when the fluid pressure on the inlet side is higher than the cracking pressure. The ball closes with the backpressure or via the spring, effectively sealing the orifice when the inlet pressure does not exceed the cracking pressure (pressure needed to overcome spring force), backpressure, or both.

The wastewater or sewage pump’s discharge pipe is fitted with ball check valves. The valve makes sure that after the pump stops, the effluent does not return to the sewage pit or wet well. These guards are against hydraulic shock and running backward-related damage to the pump. By not re-pumping the fluid that would typically drain back into the wet well after each pumping cycle, energy costs are decreased.

Consider factors while choosing a ball check valve

Pressure drop: When choosing a ball check valve, it is critical to understand the pressure drop within the flow management system. The flow is controlled by variations in system pressure, which also affects how well the ball check valve works. The reverse pressure drop, which occurs when the downstream pressure is greater than the upstream pressure, determines how tightly the valve closes off during backflow. A minimum pressure difference is required between the input and output ports of a ball check valve. When selecting a valve, make sure it satisfies this demand and take the required maximum pressure into account.

Operating environment: When choosing the housing materials, it is important to consider the ambient heat of the valve’s functioning. When temperatures are high, brass is a great material for valve housing.

Lifespan (maintenance): To determine the amount of maintenance necessary, take into account the typical lifespan intended for the valve. Ball check valves made of stainless steel have a high level of resistance to abrasion, pressure, and temperature.

Media: If a gas or corrosive liquid is the operating medium, PVC ball check valves are a fantastic option. However, compared to valves made of brass and steel, these valves have lower pressure ratings.

Four different types of ball check valves

Sinking Ball Check Valves

It is specifically made for preventing Storm Water, Wastewater, and Sewage Backflow in residential, commercial, municipal, and industrial applications. Sewage pumps, submersible wastewater lift stations, and any application involving viscous liquids or slurries are where they are most frequently used. Vertical placement is ideal for a ball check since it ensures that gravity will always seat the ball properly. The static head must be at least 20 feet of water, though, if the ball check valve is to be used in a horizontal arrangement. The suggested range for flow velocity is 3–5 feet/second.

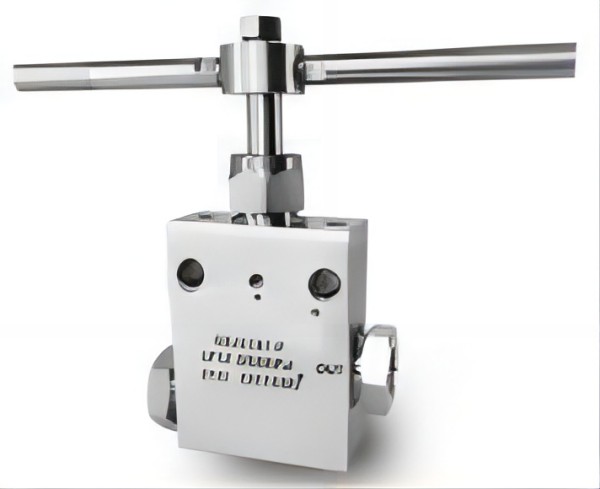

Floating Ball Check Valves

Checking the floating ball, vacuum or anti-flooding applications requires valves. In flood control applications, a floating ball is utilized to stop the overflow of rising water and stop backflow from drains. Additionally, they serve as an air vent to release air during tank and pipe filling. For proper sealing, floating ball check valves must only be mounted vertically and have a minimum of 10 feet of static head.

Buttweld ball check valves

For the inlet or outlet ports of these valves, a butt weld connection is provided.

Soldered ball check valves

These valves’ ends are attached to the pipe fittings by soldering. For more information, see our article on soldering ball valves.

Advantages of ball check valve

Small size

Easy to use

Inexpensive

Be installed in lines with both horizontal and vertical flow

Handles high pressure and large fluid volume with various media like gas, air, steam, vapor, or water

Ball rotation ensures the valve’s self-cleaning

Renewable seat rings are available

Summary

This article provides a summary of ball check valves, including their construction, working principle, different types, key specifications, and advantages. Wingoil is a professional manufacturer of ball check valves. If you have any needs, Please contact us, and we will be happy to develop a customized solution for you.