Everything You Need to Know about Hydrostatic Test Pumps

Hydrostatic test pumps play a crucial role in ensuring the safety and integrity of various systems that rely on pressurized fluids. These pumps are specialized tools used in hydrostatic testing, a process that involves applying high-pressure water to a system to identify potential weaknesses and leaks. This testing procedure is critical for preventing catastrophic failures and protecting lives and property.

What are Hydrostatic Test Pumps?

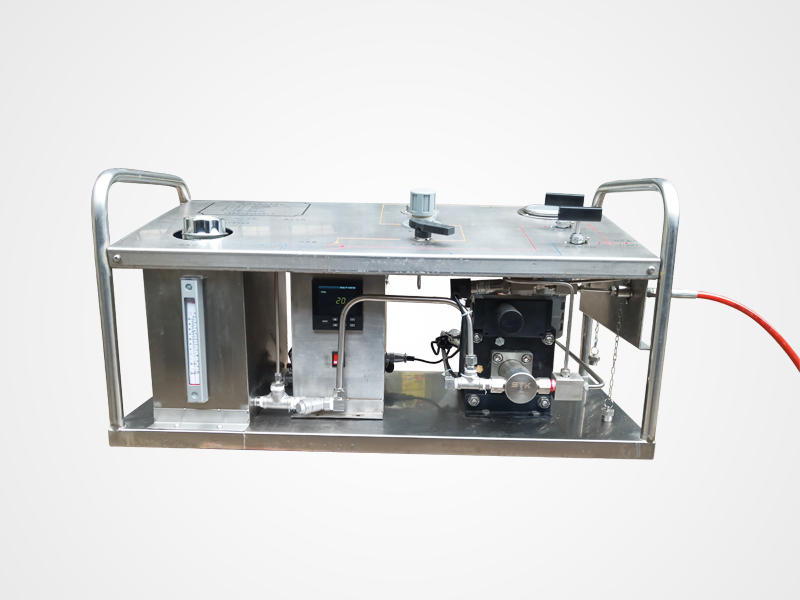

Hydrostatic test pumps are self-contained units designed to generate and maintain high pressure within a system. They typically consist of a pump mechanism, a pressure gauge, a reservoir, and a system of valves and hoses. The pump mechanism, powered by either manual operation, electricity, or a gasoline engine, forces water from the reservoir into the system being tested. The pressure gauge allows the operator to monitor and control the applied pressure, ensuring adherence to specific testing requirements. Valves and hoses facilitate the connection of the pump to the system and control the flow of water during the test.

Why is Hydrostatic Testing Important?

Hydrostatic testing is not just a “crucial safety measure” or something that “serves several vital purposes.” It is an absolutely necessary procedure for guaranteeing the safe and reliable operation of various pressurized systems across numerous industries. Here’s a breakdown of the critical reasons why:

1. Early Leak Detection: Hydrostatic testing acts as a highly effective method for identifying and uncovering leaks within pressurized systems. These leaks might be too small or inconspicuous to be detected during normal operation, potentially leading to serious consequences down the line. By intentionally pressurizing the system beyond its usual operating level, even the smallest leaks become easily identifiable, allowing for timely repairs and maintenance to prevent future failures.

2. Verifying Structural Integrity: During hydrostatic testing, the system is subjected to a pressure significantly higher than its standard operating pressure. This simulates extreme conditions that the system might encounter in unforeseen circumstances. By successfully withstanding this intensified pressure, the test verifies the system’s structural integrity and its ability to handle the intended load without any risk of failure. This proactive approach helps to prevent potential accidents, equipment damage, and any associated safety hazards or financial losses.

3. Regulatory Compliance: In many industries, including construction, fire protection, and power generation, strict regulations mandate regular hydrostatic testing of critical equipment. These regulations are established by governing bodies and industry standards to ensure the overall safety and reliability of the systems and the protection of people and property. By adhering to these regulations and conducting regular hydrostatic testing, companies demonstrate their commitment to safety and comply with established guidelines, avoiding potential legal ramifications or operational disruptions.

How Hydrostatic Test Pumps Work?

Operating a hydrostatic test pump involves a series of crucial steps that ensure the safe and effective execution of the testing procedure. Here’s a detailed breakdown of each step:

1. System Preparation

- Isolation: The system being tested needs to be completely isolated from any connected systems or equipment. This prevents unintended pressurization of other components and ensures the test focuses solely on the designated system.

- Drainage: The system is then thoroughly drained of any existing liquid or water. This eliminates potential air pockets that can interfere with the test’s accuracy and ensures the system is ready to receive the pressurized water.

- Venting: Vent lines within the system are opened to release any trapped air pockets. Air pockets can significantly alter the test results by creating areas of lower pressure or causing inaccurate gauge readings. Releasing trapped air ensures a consistent and reliable testing environment.

2. Connection and Setup

- Pump Connection: The hydrostatic test pump is connected to the system using appropriate hoses and fittings. These connections must be secure and leak-proof to prevent pressure loss and ensure the test’s integrity.

- Pressure Relief Valve: If the system has pressure relief valves, they are temporarily disabled during the test. These valves are designed to automatically release pressure when it exceeds a specific limit. Disabling them allows for accurate testing of the system’s true pressure tolerance.

3. Filling and Pressurization

- Pump Activation: Once the connections are secure and the system is prepared, the pump is activated. This draws water from the pump’s reservoir and begins to fill the system.

- Gradual Pressurization: The operator gradually increases the pressure using the pump’s controls. This controlled approach minimizes the risk of sudden pressure surges that could damage the system.

- Pressure Monitoring: The operator closely monitors the pressure gauge as the system fills. This ensures the pressure reaches the required test pressure, which is typically specified in the testing protocol or relevant regulations.

4. Holding and Inspection

- Pressure Holding: Once the desired pressure is reached, it is maintained at a constant level for a predetermined period, typically ranging from 15 to 30 minutes. This holding period allows for any potential leaks or weaknesses in the system to become evident.

- Visual Inspection: During the holding period, the system is thoroughly inspected for any signs of leaks, bulges, or other signs of weakness. This visual inspection is crucial for identifying any areas that might compromise the system’s integrity.

5. Release and System Reset

- Controlled Release: After the holding period is complete, the pressure is gradually released using a controlled venting process. This prevents sudden pressure drops that could damage the system or cause injuries.

- Air Venting: Trapped air within the system is carefully vented to avoid pressure surges during the release process. This ensures a safe and controlled pressure reduction.

6. Disconnection and System Restoration

- Disconnection: The pump and hoses are disconnected from the system once the pressure has been fully released.

- Thorough Draining: The system is then thoroughly drained of any remaining test water to prevent corrosion or other potential issues.

- Repair and Reset: Any identified leaks or weaknesses are addressed and repaired before the system is reset and placed back into service.

Different Types of Hydrostatic Test Pumps

Hydrostatic test pumps come in a variety of configurations to match the diverse needs of various testing applications. Here’s a detailed breakdown of the different types categorized by their key differentiating features:

1. Power Source

- Manual: These pumps are operated entirely by hand, requiring physical effort from the user. They are typically best suited for low-pressure testing applications or situations where portability is critical. Due to the physical exertion involved, manual pumps are not ideal for extended testing periods or high-pressure testing requirements.

- Electric: Electrically powered pumps offer greater ease of operation compared to manual versions. They provide consistent and controllable pressure making them ideal for applications requiring precise control or testing larger systems. Additionally, electric pumps are a preferred choice when manual operation is impractical due to the size or weight of the pump or the testing environment.

- Gasoline-powered: These pumps offer the highest level of portability among the three types. They are well-suited for use in remote locations where access to electricity is limited. However, gasoline-powered pumps generate noise and fumes, requiring additional safety precautions during operation, such as proper ventilation and adherence to handling and storage regulations.

2. Pressure Capacity

- Low-pressure: These pumps are designed for testing systems with pressure ratings below 300 psi (pounds per square inch). They are commonly used in domestic plumbing applications where the pressure typically falls within this range.

- Medium-pressure: These pumps can handle pressures ranging from 300 psi to 1000 psi. This makes them suitable for testing fire sprinkler systems, hydraulic lines, and other medium-pressure systems found in various applications.

- High-pressure: High pressure hydro test pumps are specifically designed for testing high-pressure systems exceeding 1000 psi. They are often used in industrial settings for applications involving boilers, pressure vessels, and high-pressure piping systems. Choosing the appropriate pressure capacity is crucial, as using a pump with insufficient pressure can lead to inaccurate test results and potential safety hazards.

3. Portability

- Hand-operated: These are compact and lightweight pumps, making them ideal for situations requiring easy transportation and use in confined spaces. Their small size allows for easier maneuvering and access to tight areas. However, their reliance on manual operation limits their suitability for large-scale or high-pressure testing.

- Cart-mounted: These pumps are mounted on wheeled carts, providing improved portability compared to hand-operated versions. This makes them suitable for testing larger systems or situations where frequent movement between testing locations is necessary. The cart facilitates easier transportation and reduces the physical exertion required for the user.

- Trailer-mounted: These are heavy-duty pumps mounted on trailers, making them ideal for high-pressure testing applications in industrial settings. Their size and weight necessitate transportation using a trailer and are typically not suitable for smaller testing environments. However, they offer the highest pressure capacity and are well-suited for demanding industrial testing needs.

How to Choose the Right Hydrostatic Test Pump?

Choosing the most suitable hydrostatic test pump requires a careful evaluation of several crucial factors that influence its effectiveness for your specific testing needs. Here’s a detailed breakdown of these key considerations:

1. Required Pressure Rating

The pressure capacity of the pump you choose must consistently exceed the maximum operating pressure of the system you intend to test. Selecting a pump with an insufficient pressure rating can lead to several detrimental consequences:

- Inaccurate Test Results: If the pump cannot generate enough pressure to fully test the system, the results might be misleading or unreliable, potentially indicating a pass when the system might actually have weaknesses at higher pressures.

- Potential Safety Hazards: Using a pump with inadequate pressure capacity creates a potential safety hazard. During real-world operation, the system could be exposed to pressures exceeding the test pressure, leading to unexpected failures and possible injuries or damage.

Therefore, it’s essential to carefully evaluate the maximum operating pressure of the system being tested and ensure the chosen pump’s pressure capacity significantly surpasses this value.

2. Volume of the System Being Tested

The reservoir capacity of the hydrostatic test pump needs to be sufficient to completely fill the system being tested and maintain the required pressure throughout the entire holding period. Using a pump with an inadequate reservoir size can lead to two main issues:

- Pressure Fluctuations: If the reservoir cannot hold enough water to fill the entire system, pressure fluctuations might occur during the test. These fluctuations can compromise the accuracy of the test results and make it difficult to determine if the system is truly leak-proof.

- Incomplete Testing: If the reservoir runs out of water during the holding period, the test might be interrupted prematurely. This incomplete testing leaves uncertainties about the system’s integrity and could potentially lead to safety risks in the future.

To ensure a reliable and complete test, the chosen pump’s reservoir capacity must be large enough to accommodate the entire volume of the system being tested and sustain the required pressure for the entire holding period.

3. Portability Needs

The size and weight of the hydrostatic test pump should be carefully considered in relation to the work environment where it will be used. Here’s a breakdown of the different types of pumps and their suitability for various situations:

- Hand-operated or Cart-mounted: These pumps are ideal for situations requiring easy transportation and use in confined spaces due to their compact size and lighter weight. They allow for easier maneuvering and access in tight environments. However, their reliance on manual operation or limited portability might not be suitable for large-scale testing or testing in remote locations requiring frequent relocation.

- Trailer-mounted: These are heavy-duty pumps designed for high-pressure testing applications in industrial settings. Their large size and weight necessitate transportation using a trailer. While they offer the highest pressure capacity, their limited portability makes them unsuitable for smaller testing environments or situations requiring frequent movement.

It’s crucial to select a pump with a portability level that aligns with the accessibility and size constraints of your testing environment.

4. Budget

Hydrostatic test pumps come in a variety of price ranges depending on their features, capabilities, and brand. It’s important to strike a balance between affordability and functionality to meet your specific testing needs. While higher-priced pumps might offer greater features, higher pressure capacities, and increased portability, lower-priced options might be sufficient for simpler testing situations with lower pressure requirements.

Applications of Hydrostatic Test Pumps

Hydrostatic test pumps play a vital role in maintaining the safety and reliability of various pressurized systems across numerous industries. Here’s a detailed breakdown of the crucial applications of these pumps:

1. Fire Sprinkler Systems

Fire sprinkler systems are subjected to regular hydrostatic testing to guarantee their proper operation during a fire emergency. This testing process verifies the system’s ability to:

- Withstand the designated pressure: The test ensures the system can handle the pressure it’s designed for without failing, allowing it to function effectively during a fire.

- Identify leaks and weaknesses: The test helps identify any leaks or weak points within the system that could prevent proper water distribution in case of a fire. Addressing these issues proactively minimizes the risk of malfunction and ensures the system’s overall effectiveness in protecting lives and property.

2. Plumbing Lines

Hydrostatic testing is performed on both newly installed and repaired plumbing lines before placing them into service. This testing serves two critical purposes:

- Leak Detection: The test effectively detects leaks that might be too small or inconspicuous to be identified during regular visual inspections. These even minor leaks, if left undetected, could lead to significant water damage and pose potential safety hazards.

- Functionality Verification: The test verifies the overall functionality of the plumbing system by ensuring it can withstand the intended water pressure without any issues. This helps to prevent potential bursts, leaks, or malfunctions that could disrupt water flow and cause inconvenience or damage.

3. Boilers and Pressure Vessels

Various industries, including power generation and chemical processing, rely on boilers and pressure vessels. These critical components undergo periodic hydrostatic testing to ensure their:

- Structural Integrity: The testing process verifies that the vessels can withstand the designed operating pressure without any structural weaknesses or failures. This helps to prevent potential catastrophic accidents and protects personnel and surrounding areas from harm.

- Safety Compliance: Many industries have strict regulations mandating regular testing of boilers and pressure vessels. Hydrostatic testing helps ensure compliance with these regulations, demonstrating the commitment to safety and operational integrity.

4. Hydraulic Systems

Many types of machinery and equipment rely on hydraulic systems that utilize pressurized fluids to function. Hydrostatic testing plays a crucial role in maintaining the integrity of these systems by:

- Identifying Leaks and Weaknesses: The test helps detect leaks, weaknesses, or potential component failures within the hydraulic system. Addressing these issues promptly prevents malfunctions, performance issues, or even equipment breakdowns.

- Ensuring Operational Efficiency: By identifying and addressing potential problems within the hydraulic system, hydrostatic testing helps to maintain optimal performance and efficiency. This translates to reliable operation, reduced downtime, and cost savings in the long run.

Conclusion

Regular hydrostatic testing plays a vital role in maintaining the safety and reliability of systems that rely on pressurized fluids. By employing appropriate hydrostatic test pumps and adhering to safety protocols, technicians and inspectors can ensure the integrity of these systems, preventing failures that could lead to property damage, injuries, or even fatalities.