Frac Ball, Coated Dissolvable Ball

- Frac balls are inserted into wells to build up pressure in the ground. WINGOIL frac ball can be used as a test for the HCL Acid Resistance Test.

- The dissolvable frac ball is composed of Dissolvable Magnesium Alloy material that can withstand the extreme pressures and temperatures encountered during the fracking process. Once the fracturing operation is complete, the ball begins to dissolve, eliminating the need for costly and time-consuming milling operations.

Share to

Dissolvable Frac Ball HCL Acid Resistance Test

Experimental purpose: Obtain the acid corrosion resistance of the coating soluble ball in a certain temperature and certain concentration of HCL solution through experimental observation

Experimental Steps

1. Prepare experimental equipment, soluble ball, solute (HCL), clean water, beaker, balance, vernier caliper Constant temperature water bath

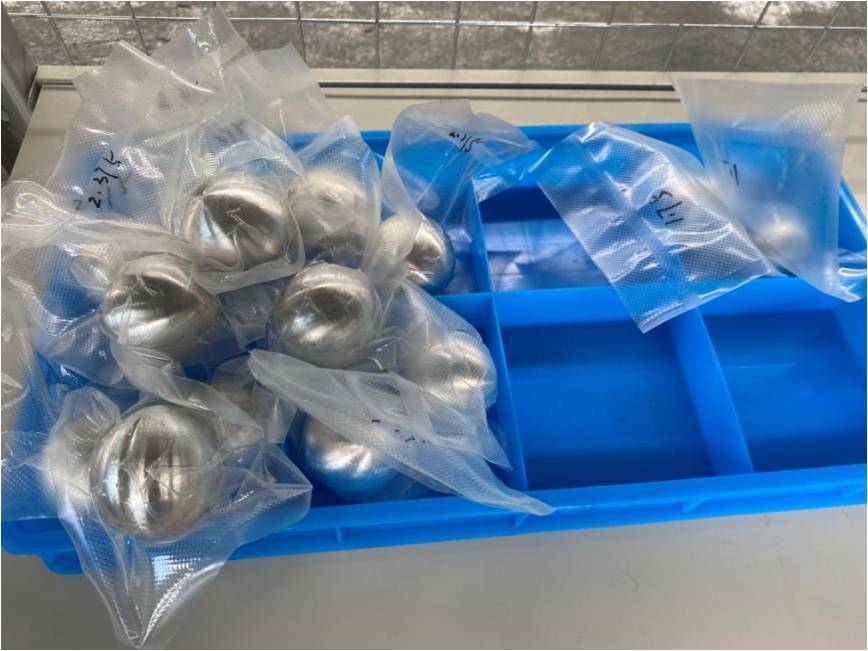

2. Check the appearance and size of the soluble ball, and take a photo

3. Prepare 20% HCL solution

4. Immerse the coating soluble ball in HCL solution

5. The constant temperature box maintains the HCL solution at a certain temperature, and observes the acid corrosion resistance of the soluble ball

6. Take out the soluble ball at intervals, check the appearance, shape and size of the soluble ball, and record the soluble ball weight, reconstitute the acid solution, continue to observe the corrosion resistance of the soluble ball

Test index: Record the corrosion resistance of the soluble ball every 24 hours.

Experimental considerations: Every time during an acid resistance check, pay attention to safety, record relevant data and take pictures clearly.

| Date | Test location | Model |

| 2020.11.15.10:00 | Wingoil Lab | Dissolvable Magnesium aluminum alloy ball with Protection Coating |

| Temperature | Fluid | HCL Acid |

| 70℃ | HCl | 20% |

Solution Preparation and Appearance of Acid-resistant Soluble Ball

Remarks (appearance of soluble ball): smooth and bright surface

Remarks (appearance of soluble ball): The soluble ball is corroded with a few holes, the largest hole diameter is 6mm, and the depth is 2mm.

Remarks (appearance of soluble ball): The soluble ball is corroded with notches and holes, the notch diameter is 25mm, and the depth is 8mm.

Remarks (appearance of soluble ball): The gap of the soluble ball is slightly deepened, the gap diameter is 30mm, and the depth is 11mm.

Experimental Results

The coating soluble ball is at 70℃, 20% concentration of HCL solution, within 24 hours, the acid corrosion resistance is good, and the soluble ball coating is intact; 24 to 48 hours, the soluble ball has a few holes, 48 to 60 hours, A slightly larger gap appears, and within 60 to 72 hours, the gap is slightly deepened and enlarged.

|

Grade | Max. Tensile Strength (Mpa) | Max. Pressure Strength (Mpa) | Yield Strength (Mpa) | Shear Strength (Mpa) | Elongation (%) | Elasticity Modulus (GPa) | Hardness (HB) | Testing Conditions | Dissolution Rate mg/(cm2*hr) | Dissolution Rate mm/hr | Density (g/cm3) | Sample Rod Size | |

| Temp (℃ ) | Concentration of CL | ||||||||||||

|

HH-006 | 380 | 430 | 260 | 140 | >3 | 44.8 | >80 | 93 | 3% | 50-70 | 0.56 | 1.83 | Φ110×1000 |

| 380 | 430 | 260 | 140 | >3 | 44.8 | >80 | 93 | 1% | 20-35 | 0.35 | 1.83 | Φ110×1000 | |

| 240 | 180 | 26 | 150 | Φ90 | |||||||||

| HH-006A | 320 | 366 | 240 | 162 | >6 | 44.8 | >75 | 93 | 3% | 50-70 | 0.56 | 1.83 | Φ70×1000 |

| 320 | 366 | 240 | 162 | >6 | 44.8 | >75 | 93 | 1% | 20-30 | 0.35 | 1.83 | Φ70×1000 | |

| HH-008 (012) | 410 | 486 | 290 | 197 | >5 | 45 | >100 | 93 | 3% | 40-55 | 0.46 | 1.94 | Φ110×1000 |

| 410 | 486 | 290 | 197 | >5 | 45 | >100 | 93 | 1% | 15-25 | 0.3 | 1.94 | Φ110×1000 | |

| 310 | 260 | 12 | 250 | Φ90 | |||||||||

| HH-008A | 410 | 486 | 290 | 197 | >5 | 45 | >100 | 93 | 3% | 60-80 | 0.68 | 1.94 | Φ110×1000 |

| 410 | 486 | 290 | 197 | >5 | 45 | >100 | 93 | 1% | 35-50 | 0.42 | 1.94 | Φ110×1000 | |

| HH-008B | 350 | 408 | 240 | 176 | >7 | 44.8 | >85 | 93 | 3% | 30-45 | 0.43 | 1.93 | Φ110×1000 |

| 350 | 408 | 240 | 176 | >7 | 44.8 | >85 | 93 | 1% | 15-25 | 0.25 | 1.93 | Φ110×1000 | |

| HH-010 | 200 | 325 | 130 | 99 | 24 | 44.3 | ≥40 | 93 | 3% | 20-30 | 0.12 | 1.8 | Φ110×1000 |

| HH-011 | 410 | 486 | 300 | 197 | >4.5 | 44.8 | >100 | 93 | 3% | 20-35 | 0.28 | 1.93 | Φ110×1000 |

| 410 | 486 | 300 | 197 | >4.5 | 44.8 | >100 | 93 | 1% | 8-15 | 0.17 | 1.93 | Φ110×1000 | |

| HH-016 | 280 | 350 | 190 | 127 | 13 | 44.8 | >60 | 93 | 3% | 40-55 | 0.46 | 1.8 | Φ110×1000 |

| 280 | 350 | 190 | 127 | 13 | 44.8 | >60 | 93 | 1% | 15-25 | 0.25 | 1.8 | Φ110×1000 | |

| HH-017 | 210 | 352 | 150 | 99 | 18 | 44.8 | >60 | 93 | 3% | 40-55 | 0.48 | 1.8 | Φ110×1000 |

| 210 | 352 | 150 | 99 | 18 | 44.8 | >60 | 93 | 1% | 15-25 | 0.19 | 1.8 | Φ110×1000 | |

| HH-017K | 235 | 352 | 170 | 120 | 15 | 44.8 | >60 | 93 | 3% | 100-130 | 0.75 | 1.81 | Φ110×1000 |

| 235 | 352 | 170 | 120 | 15 | 44.8 | >60 | 93 | 1% | 50-70 | 0.45 | 1.81 | Φ110×1000 | |

| HH-018 | 230 | 362 | 170 | 130 | 12 | 44.4 | ≥45 | 50 | 0.84% | 35-50 | 0.42 | 1.82 | Φ110×1000 |

| HH-019 | 235 | 352 | 170 | 120 | 7 | 44.5 | >55 | 93 | 3% | 160-190 | 0.86 | 1.8 | Φ110×1000 |

| 235 | 352 | 170 | 120 | 7 | 44.5 | >55 | 45 | 0.10% | 20-40 | 0.15 | 1.8 | Φ110×1000 | |

| HH-021 | 305 | 415 | 220 | 140 | >3 | 44.5 | >65 | 43 | 0.05% | 80-100 | 0.81 | 1.94 | Φ110×1000 |

| HH-022 | 305 | 415 | 220 | 155 | >4.5 | 44.8 | >80 | 43 | 0.05% | 45-60 | 0.45 | 1.94 | Φ110×1000 |

| HH-023 | 275 | 385 | 180 | 140 | 8 | 44.5 | >65 | 43 | 0.05% | 20-35 | 0.27 | 1.93 | Φ28×1000 |

| HH-024 | 280 | 415 | 240 | 145 | >4.5 | 44.8 | >70 | 43 | 0.05% | 45-65 | 0.46 | 1.83 | Φ60×1000 |

| HH-808 | 370 | 486 | 262 | 197 | >3.5 | 44.8 | >100 | 50 | 0.84% | 40-60 | 0.44 | 2.16 | Φ110×1000 |

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————